Answer: Transformer protection is important to prevent damage to expensive equipment, ensure system reliability, and enhance safety. It detects faults like overloads or short circuits, isolates the affected transformer, and minimizes downtime. This helps maintain power system stability, protects against safety hazards, and reduces repair costs. Transformer protection basically divided into two types. One is Electrical Protection and it is designed based on Electrical parameters like Current, Voltage, Frequency, and Impedance. The second type of protection is Mechanical Protection and it is designed based on Mechanical parameters like Temperature, Pressure, Density, etc.

Transformer-Electrical Protection Types with relay number:

Over current Protection (51):

This protection is designed to detect and respond to excessive current flow, which can be caused by short circuits or overloads. Devices like fuses and over current relays are used to interrupt the circuit when the current exceeds a predetermined level.

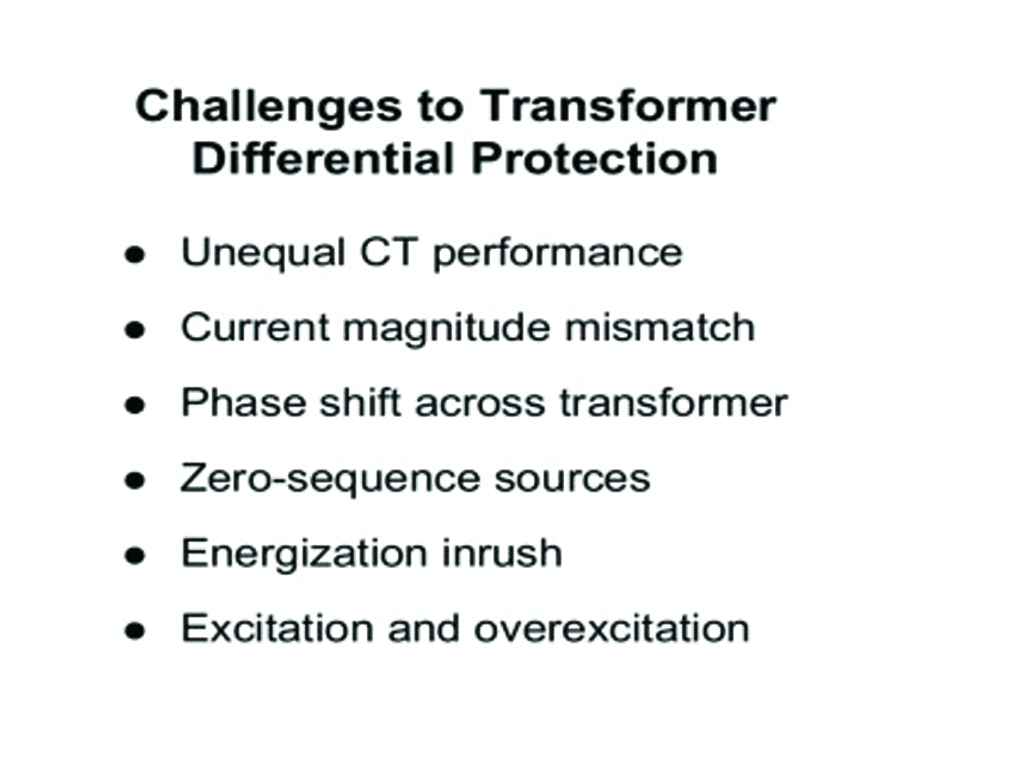

Differential Protection (87):

Detects internal faults by comparing the current entering and leaving the transformer. If there is a difference, it indicates a fault within the transformer.

Buchholz Relay Protection (87R):

A gas-operated relay used for detecting internal faults in oil-filled transformers. It senses gas buildup caused by faults like insulation breakdown or arcing.

Earth Fault Protection (50N/51N):

Protects against earth faults by detecting any leakage of current to the ground, preventing damage to the transformer or system.

Over Voltage-59/Under Voltage-27 Protection:

Protects the transformer from voltage fluctuations. It disconnects the transformer when voltage exceeds or falls below safe operating levels.

Thermal Protection (49):

Monitors the transformer’s temperature to prevent overheating. If the temperature exceeds a set threshold, the protection system will trigger a shutdown.

Protection against Unbalanced Loads (46):

Detects when the transformer is operating with an unbalanced load, which can cause overheating or damage, and disconnects it if necessary.

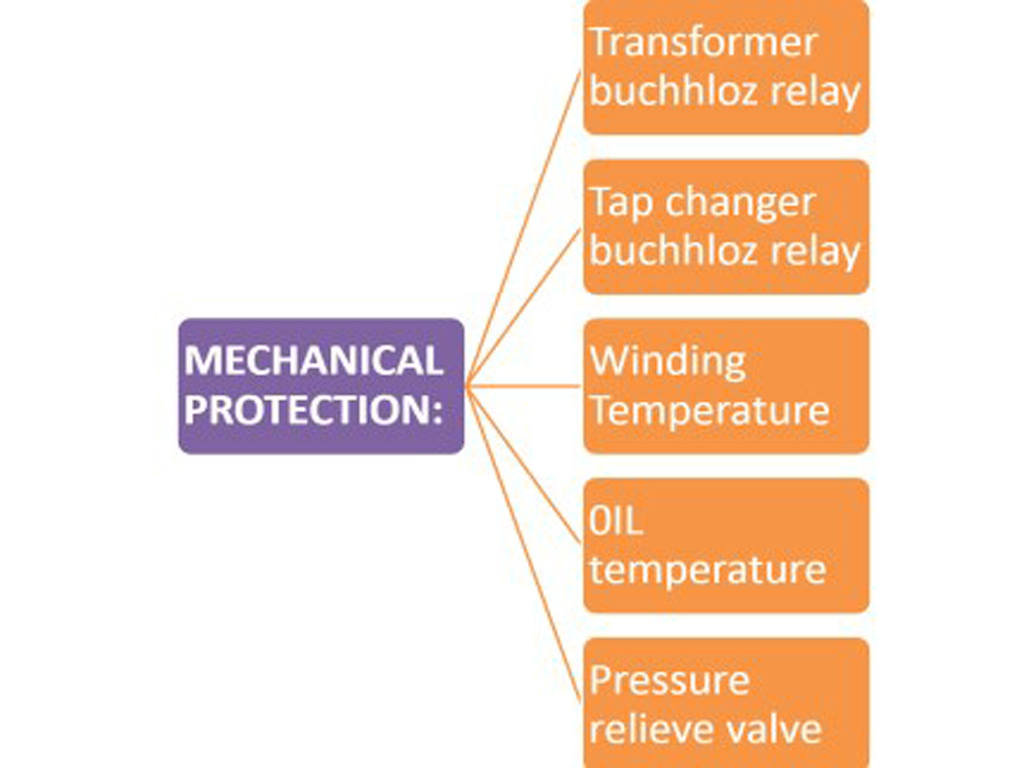

Transformer-Mechanical Protection Types with relay number:

Transformer mechanical protection types are designed to safeguard the physical integrity of transformers against mechanical faults or stresses. These protections are typically designed to prevent issues such as excessive vibrations, thermal stresses, or structural damage. Below are common mechanical protection types for transformers, along with their corresponding relay numbers:

Buchholz Relay Protection (87R)

Relay Number: 87R

Function: Protects oil-filled transformers by detecting gas buildup due to internal faults such as insulation failure or arcing. It triggers an alarm or disconnects the transformer if a fault is detected. This relay works by sensing the gas produced by the fault inside the transformer tank.

Pressure Relief Valve Protection

Relay Number: No specific relay number, typically mechanical device

Function: When the pressure inside the transformer tank increases due to gas accumulation (from a fault or overheating), the pressure relief valve opens to release pressure and prevent damage. This is a mechanical safety device that does not typically use relays but is part of transformer mechanical protection.

Transformer Explosion Protection (Pressure Transducer)

Relay Number: Often combined with 87R or other protective relays

Function: Pressure sensors or transducers monitor internal pressure within the transformer. When pressure exceeds safe limits (often due to internal faults), the relay triggers protective actions such as tripping the transformer. The pressure transducer may also provide feedback to a digital relay for integrated protection.

Tap-Changer Protection (NC or 52T)

Relay Number: 52T (Tap-Changer Control Relay)

Function: Protects the mechanical tap changer, which adjusts the voltage levels of the transformer. This protection prevents mechanical damage to the tap changer by monitoring its operations. Over current or mechanical failures in the tap changer are detected and the system trips if necessary.

Vibration Protection

Relay Number: 86 (Lockout relay)

Function: Vibration sensors are used to detect abnormal mechanical vibrations in the transformer tank. Excessive vibrations can indicate mechanical problems or issues with cooling systems. The relay will trip if vibration thresholds are exceeded, preventing potential mechanical damage.

Oil Temperature Protection (49)

Relay Number: 49

Function: This is a thermal protection scheme for oil-filled transformers. The oil temperature is monitored, and the relay will initiate an alarm or trip the transformer if the oil temperature exceeds safe operating levels. This helps prevent mechanical damage caused by overheating.

Transformer Tank Monitoring (for Leaks or Deformation)

Relay Number: Relays typically combined with other protective devices

Function: In some cases, mechanical sensors detect tank deformation, leaks, or abnormal expansion. These may not have a specific relay number but are integrated into the protection systems for transformers.

Sudden Pressure Relay (87SP)

Relay Number: 87SP

Function: This relay protects the transformer against sudden pressure rise, often caused by an internal fault like a short circuit. When there is a rapid buildup of gas or pressure inside the transformer, the relay triggers a trip to avoid mechanical damage or explosion.

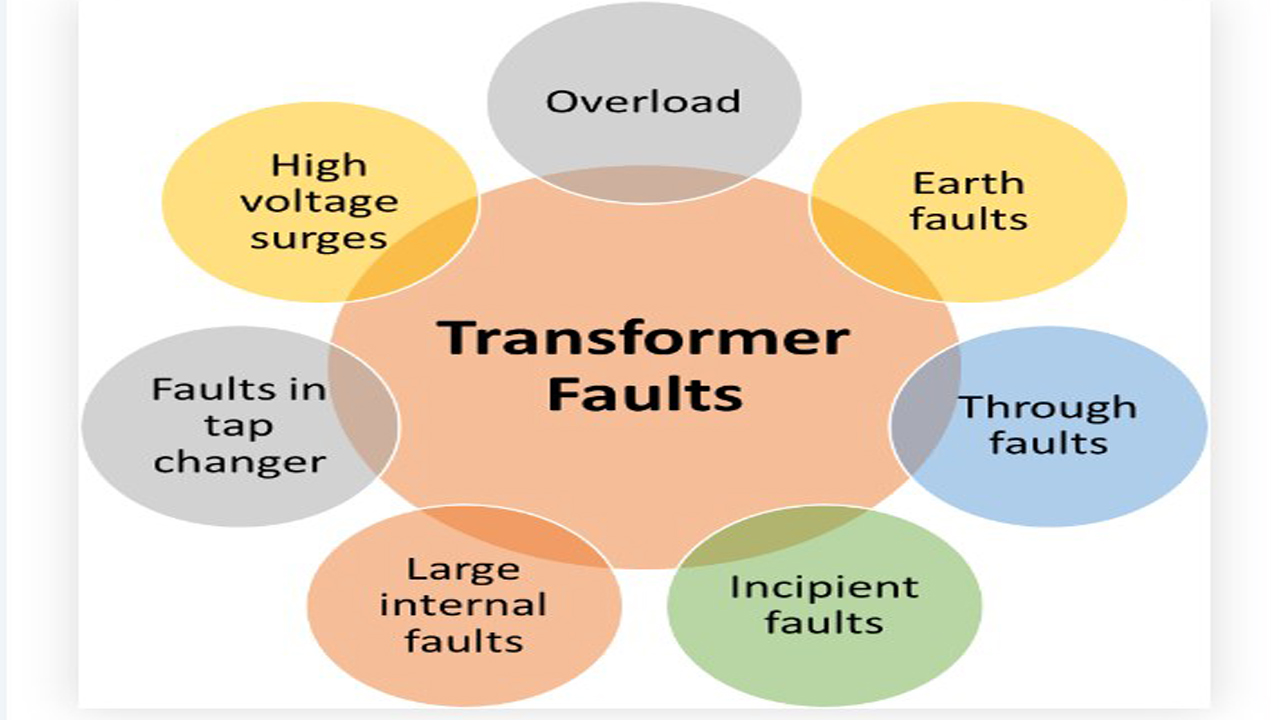

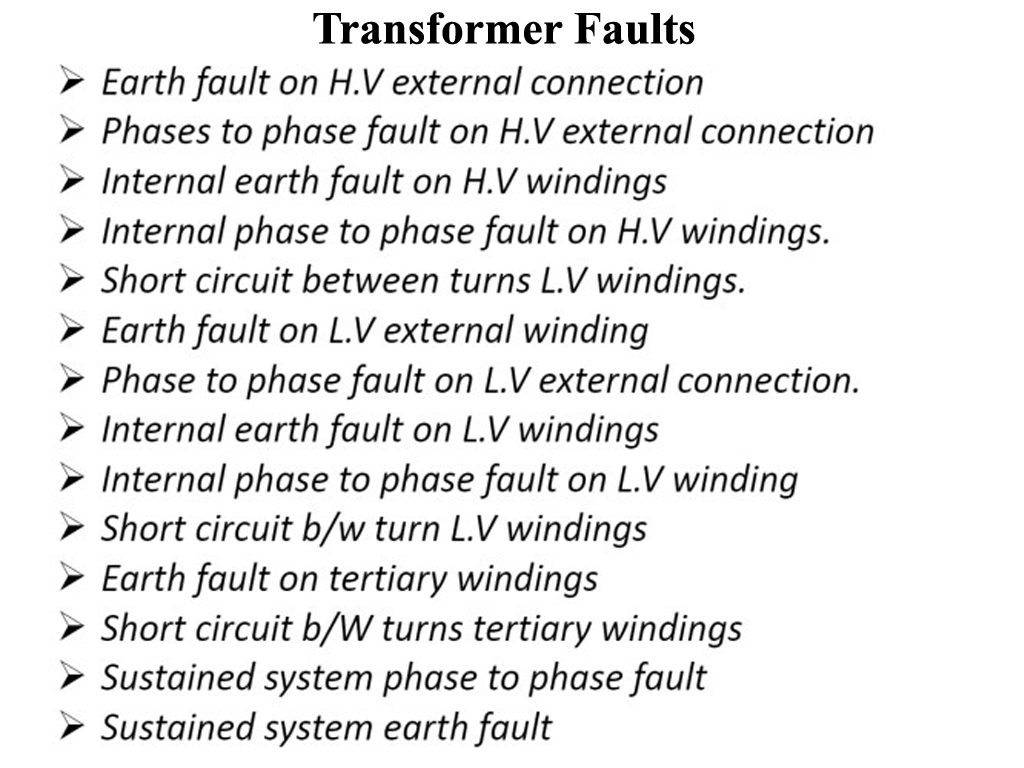

Transformers external faults and internal faults:

Transformers can experience both external and internal faults. These faults can lead to significant damage if not properly managed by protection systems. Here’s a breakdown of these types of faults:

External Faults

External faults occur outside the transformer and usually involve issues in the surrounding electrical network, impacting the transformer indirectly. These faults often lead to transformer protection systems detecting and isolating the fault quickly to minimize damage.

Short Circuits in the Power System (External Short Circuit):

Cause: A fault occurs in the connected power lines or other components of the electrical network, causing a sudden surge of current.

Impact on Transformer: The transformer is subjected to large currents, leading to potential overloads and thermal stress.

Protection: Over current protection (51) and differential protection (87) are typically used to disconnect the transformer from the system in such cases.

Ground Faults (External Earth Fault):

Cause: A short circuit to the ground occurs in the system outside the transformer.

Impact on Transformer: This causes a leakage current that can damage insulation and other components.

Protection: Earth fault protection (50N/51N) can detect leakage currents to the ground and isolate the transformer.

Over voltage or Under voltage:

Cause: External issues in the network cause the transformer to experience voltage levels above or below its rated range.

Impact on Transformer: Over voltage can cause insulation breakdown, while under voltage can result in improper operation of the transformer.

Protection: Over voltage (59) and under voltage (27) protection systems will trip the transformer if the voltage goes beyond set limits.

System Frequency Variations:

Cause: Fluctuations in frequency from the power generation side (like a power plant failure).

Impact on Transformer: Significant frequency variations can lead to mechanical and thermal stresses on the transformer.

Protection: Frequency protection relays can detect these issues and disconnect the transformer.

Internal Faults

Internal faults originate within the transformer itself, often due to physical breakdowns or failures of components such as insulation, windings, or the core. These faults are typically more damaging if not detected quickly.

Core Faults:

Cause: Faults in the transformer core, often due to insulation failure or a short circuit between the core laminations.

Impact on Transformer: Causes overheating, excessive current, and possible transformer destruction.

Protection: Differential protection (87) detects imbalances in the core, while overcurrent protection (51) may isolate the fault.

Winding Faults:

Cause: Short circuits or insulation failures in the windings due to overheating, mechanical stress, or aging.

Impact on Transformer: This can cause a large fault current, leading to possible damage to the windings and transformer failure.

Protection: Differential protection (87) can detect internal winding faults. Overcurrent protection (51) may also be used to detect winding failures.

Oil and Cooling System Failures:

Cause: Issues such as oil leakage, overheating of the oil, or malfunction in the cooling system.

Impact on Transformer: Lack of proper cooling can lead to transformer overheating, causing insulation breakdown or damage to the windings.

Protection: Oil temperature protection (49) and Buchholz relay protection (87R) are used to monitor and protect against these failures.

Buchholz Relay Detection (Gas Formation):

Cause: Internal faults, such as a fault between the windings or between a winding and the core, generate gas due to arcing or overheating.

Impact on Transformer: The accumulation of gas inside the transformer can indicate a serious fault like a winding short circuit or insulation failure.

Protection: The Buchholz relay (87R) detects gas buildup and provides an early warning or trips the transformer if necessary.

Tap Changer Malfunction:

Cause: Mechanical or electrical failure of the tap changer, which adjusts the transformer’s voltage output.

Impact on Transformer: The malfunction can cause incorrect voltage regulation or severe mechanical damage to the transformer.

Protection: Tap changer protection (52T) can detect mechanical or electrical issues in the tap changer and isolate the transformer.

In summary, external faults are typically caused by issues in the power system or network, while internal faults arise from problems within the transformer itself. Proper protection mechanisms are essential to detect both types of faults and prevent significant damage to the transformer and the power system.