Transformer

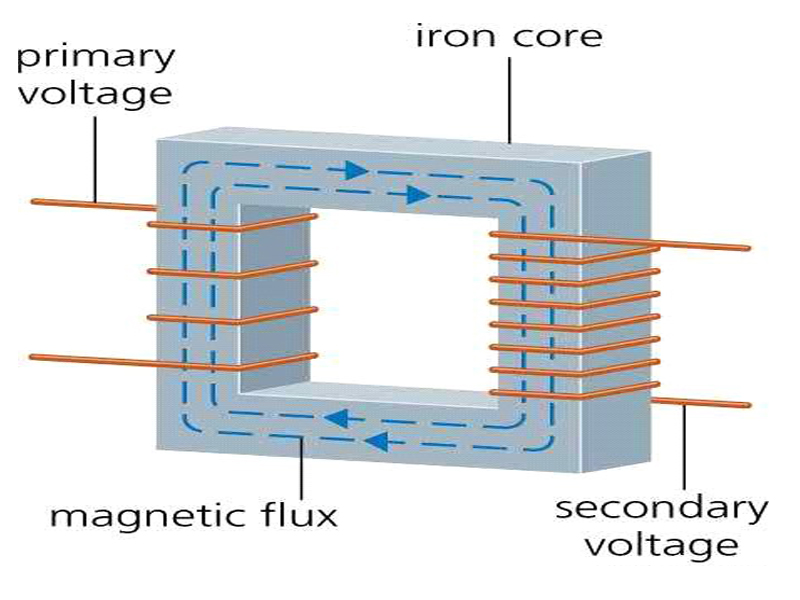

A transformer is an electro- static device that transform electrical power from one circuit to another one of the same frequency or without changing frequency. Its change the voltage level (either stepping it up or stepping it down) corresponding decrease or increase in current. It operates on the principle of electromagnetic induction. The physical basis of a transformer is mutual induction between two circuits linked by a common magnetic flux. Here two circuits means two coils which are electrically separated but magnetically linked through a path of low reluctance.

- Primary Coil: Receives the input voltage.

- Secondary Coil: Provides the output voltage.

- Core: Facilitates the transfer of energy between the coils through magnetic flux.

Transformer construction:

- Core (Magnetic Core):

The core is typically made of laminated sheets of silicon steel or grain-oriented electrical steel. These lamination’s are insulated from each other with a thin coating of varnish to prevent eddy currents (which cause heat and energy loss) from circulating through the metal. These materials are chosen because they have high magnetic permeability and low hysteresis loss.

- Windings:

The winding are typically made of copper wire (high conductivity and low resistance) or aluminum wire (lighter and more economical). The windings are insulated with materials like paper, varnish, or enamel to prevent short circuits and to ensure the transformer operates safely.

- Primary Winding: This winding is connected to the input side of the transformer. The primary winding creates a magnetic field when an alternating current (AC) flows through it.

- Secondary Winding: This winding is connected to the output side and is responsible for producing the transformed (either stepped-up or stepped-down) voltage. The secondary winding is magnetically coupled to the primary winding through the core.

- Insulation:

The insulation is typically made of oil, air, or synthetic resins. The type of insulation depends on the voltage level and the specific application of the transformer.

- Oil-filled transformers: These use mineral oil or synthetic oils to insulate and cool the windings and the core.

- Dry-type transformers: These use air or solid insulation materials (like epoxy or cast resin) and are typically used in lower voltage applications.

- Tank (Enclosure)

The tank is the outer casing of the transformer, designed to house all the internal components and provide protection from environmental elements. The tank is usually made of steel or aluminum for strength and durability. In oil-filled transformers, the tank is usually filled with transformer oil (also called insulating oil), which not only insulates but also helps with cooling by dissipating heat generated by the core and winding.

5. Cooling System

Transformers generate heat during operation, so a cooling system is needed to maintain safe operating temperatures.

- Oil Cooling: In oil-filled transformers, the oil circulates around the windings and the core, absorbing heat and dissipating it into the surrounding air. This oil is often circulated through a radiator or cooler to help reduce the temperature.

- Air Cooling: In dry-type transformers, cooling is achieved through natural air circulation or forced air cooling using fans.

- Water Cooling: For very large transformers, water cooling may be employed to assist in heat dissipation.

6. Tap Changer

A tap changer is used to adjust the voltage ratio of the transformer by selecting different tapping points on the winding. It can be manual or automatic, and it helps compensate for voltage fluctuations in the supply. Tap changers are often located on the primary winding of the transformer. Transformer have two types of tap changer.

- Off-load tap changers: Require the transformer to be disconnected from the power supply for adjustment.

- On-load tap changers: Allow voltage adjustments to be made while the transformer is in operation.

7. Conservator (for Oil-filled Transformers)

The conservator is a small tank attached to the main transformer tank, which stores extra transformer oil. It allows for expansion and contraction of the oil as it heats and cools, maintaining the proper oil level.

- Breather: The conservator is typically fitted with a breather to prevent moisture from contaminating the oil. It uses silica gel to absorb moisture from the air before it enters the oil.

8. Bushings

Bushings are typically made of porcelain or polymer insulators. Bushings are insulator assemblies that allow the electrical connections to pass through the transformer’s tank. Bushings preventing direct contact between the high-voltage parts of the transformer and the external environment.

9. Grounding

The transformer must be properly grounded to ensure safety in case of electrical faults, such as a short circuit. A grounding system prevents the buildup of dangerous voltages on the transformer’s metal parts.

10. Protective Devices

- Circuit Breakers: These are used to disconnect the transformer from the network in case of a fault or overload.

- Relays: Protective relays detect faults and send signals to the circuit breakers to protect the transformer from damage.

- Pressure Relief Valve: This valve is used in oil-filled transformers to release pressure in case of internal failure, preventing rupture.

After Installed, the transformer is subjected to high-voltage tests and checked for functionality before being commissioned into service.

Working principle of transformer

The working principle of a transformer is based on the fundamental concept of electromagnetic induction. Specifically, it relies on Faraday’s Law of Induction and Ampere’s Law to transfer electrical energy from one circuit to another through a magnetic field. When transformer is connected to an alternating current (AC) source at the primary side.

This AC current flows through the primary winding of the transformer and it creates a magnetic flux in the transformer’s core. The core is typically made of laminated steel sheets that provide a low-resistance path for the magnetic flux, minimizing energy loss. As the AC current in the primary coil changes direction, the magnetic field also changes direction and magnitude, creating a changing magnetic flux that passes through the core.

According to Faraday’s Law of Electromagnetic Induction, a changing magnetic flux through a coil of wire induces a voltage (also called electromotive force or EMF) in that coil, this induces voltage is linked to the secondary winding, and as it passes through the core, it induces an AC voltage in the secondary winding. The induced voltage in the secondary coil depends on the rate of change of the magnetic flux and the number of turns in the secondary winding.

The voltage induced in the secondary winding is related to the voltage in the primary winding by the turn’s ratio (the ratio of the number of turns in the primary coil to the number of turns in the secondary coil):

Vp/Vs=Np/Ns

Where:

- Vp = Voltage in the primary winding

- Vs = Voltage in the secondary winding

- Np = Number of turns in the primary winding

- Ns= Number of turns in the secondary winding

- If the number of turns in the secondary coil is greater than in the primary coil (Ns>Np), the transformer is a step-up transformer, meaning it increases the voltage.

- If the number of turns in the secondary coil is fewer than in the primary coil (Ns<Np), the transformer is a step-down transformer, meaning it reduces the voltage.

- The energy is transferred from the primary coil to the secondary coil through the magnetic field in the core, without any direct electrical connection between the two circuits. The power (the product of voltage and current) remains nearly the same on both sides (ignoring losses):

Pp = Ps

Where Pp is the power on the primary side, and Ps is the power on the secondary side.

- In a step-up transformer, voltage is increased, but the current decreases proportionally.

- In a step-down transformer, voltage is decreased, but the current increases proportionally.