Single-Phase Induction Motor ;

A Single-Phase Induction Motor (SPIM) is one of the most commonly used types of electric motors, especially for small appliances and household applications. It operates on a single-phase AC power supply.

A single-phase induction motor is an AC electric motor that converts single-phase electrical energy into mechanical energy using magnetic interactions. They work on the principle of electromagnetic induction, where a rotating magnetic field induces current in the rotor, causing it to rotate.

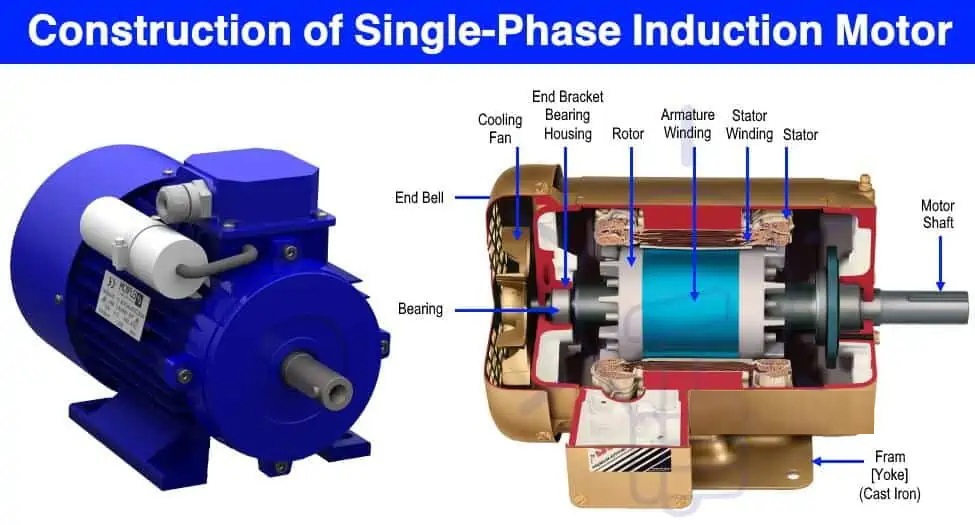

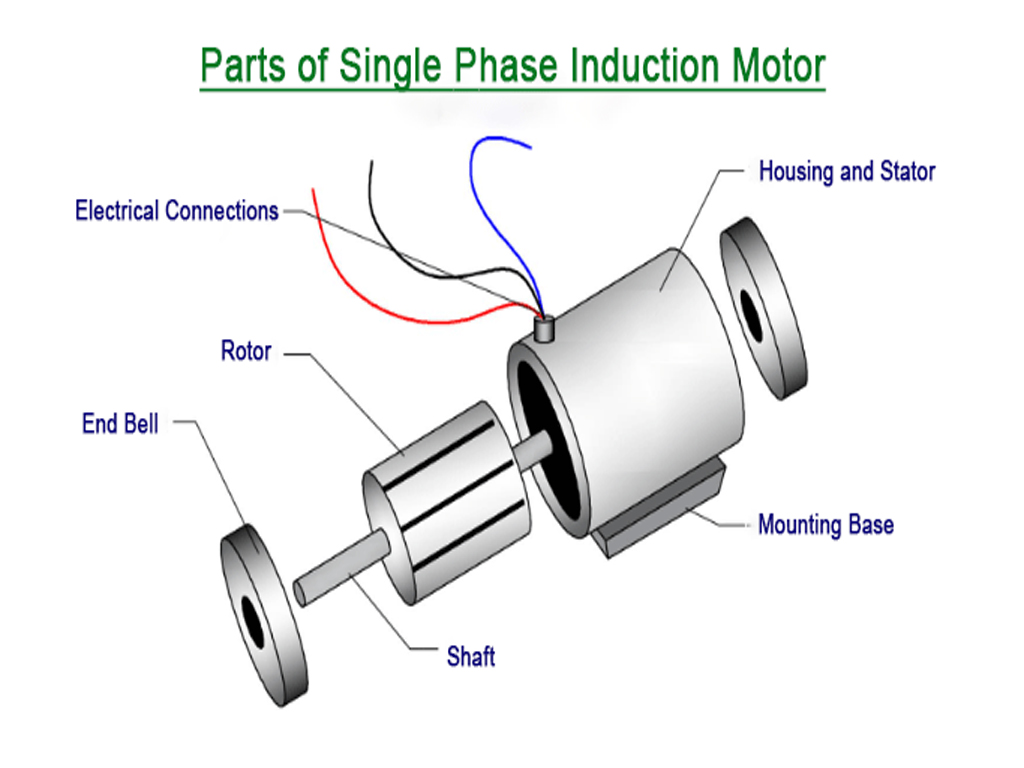

Construction of a Single-Phase Induction Motor:

The basic construction of a single-phase induction motor consists of the following main parts:

Stator:

The stator is the stationary part of the motor. It is made up of laminated sheets of silicon steel to reduce eddy currents. It has two parts:

- Main winding (or running winding): This winding is powered by the single-phase AC supply.

- Auxiliary winding (or starting winding): This winding is used for starting the motor. It is connected in parallel with the main winding but is typically connected through a capacitor or a centrifugal switch.

Rotor:

The rotor is the rotating part of the motor and is located inside the stator. It is usually a squirrel cage type (squirrel cage rotor) consisting of laminated conductors shorted at both ends by conducting rings.

End Bells:

End bells cover the ends of the stator and rotor. They support bearings that allow the rotor to rotate.

Bearings:

Bearings support the rotor shaft and enable smooth rotation.

Working Principle of a Single-Phase Induction Motor:

A single-phase induction motor works on the principle of electromagnetic induction, which states that a current-carrying conductor placed in a magnetic field experiences a force (Lorentz force).

Key Working Steps:

- When an AC current flows through the stator winding, it produces a rotating magnetic field.

- However, a single-phase AC supply creates only a pulsating magnetic field, which is not a rotating magnetic field. To overcome this, the auxiliary winding and capacitor (in some motors) are used to create a phase difference, making the overall magnetic field appear to rotate.

- The rotating magnetic field induces current in the rotor conductors, and according to Faraday’s Law of Induction, this induces a torque that causes the rotor to rotate.

- Once the motor starts running, it behaves like a three-phase induction motor.

Types of Single-Phase Induction Motors:

Split-Phase Motor:

- The most common type of single-phase induction motor.

- It uses two windings: a main winding (running winding) and an auxiliary winding (starting winding).

- A centrifugal switch disconnects the auxiliary winding after the motor reaches a certain speed.

Capacitor-Start Motor:

- Has a capacitor in series with the starting winding to improve starting torque.

- The motor is disconnected from the capacitor once it reaches full speed (via a centrifugal switch).

Capacitor-Run Motor:

- A capacitor is permanently connected to the auxiliary winding during the motor’s operation.

- Provides better efficiency and continuous running performance.

Shaded Pole Motor:

- A simple design with a shaded pole to create a rotating magnetic field.

- Generally used in low-power applications (e.g., small fans and toys).

Permanent-split capacitor (PSC) motors:

- Use a single capacitor for both starting and running.

Advantages:

- Simple construction.

- Relatively low cost.

- Self-Starting.

- Reliable and require minimal maintenance.

- Suitable for household appliances.

- They are widely available and used in various household appliances, small tools, and industrial applications.

Disadvantages:

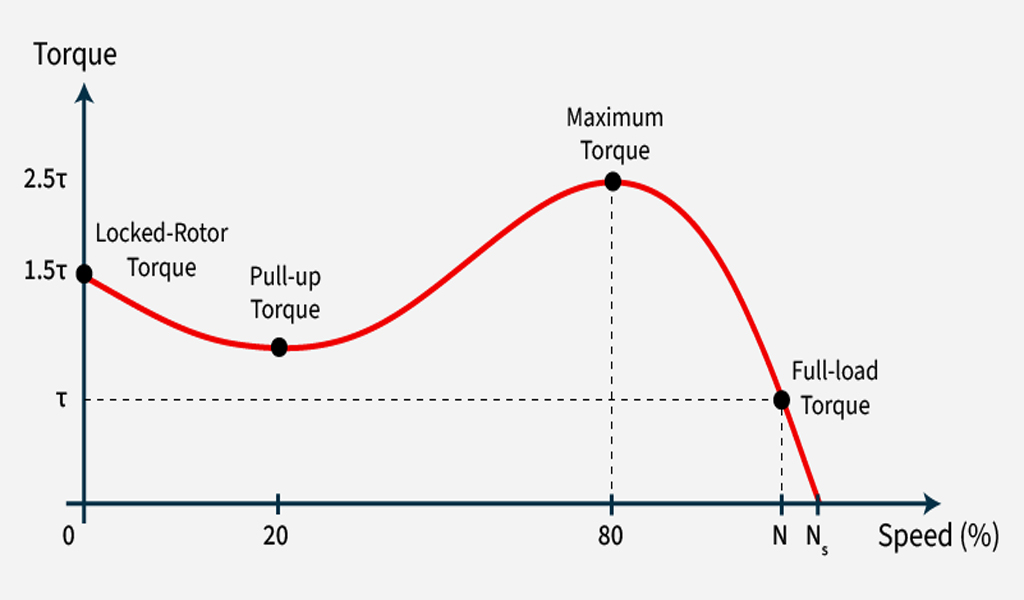

- Low starting torque.

- Lower efficiency compared to three-phase induction motors.

- Generally lower power ratings.

- Speed control is more difficult compared to other types of motors like DC motors or three-phase motors.

Applications of Single-Phase Induction Motors:

Household Appliances:

- Fans

- Washing machines

- Refrigerators

- Air conditioning units

Small Tools:

- Drills

- Blowers

- Pumps (in small capacities)

HVAC Systems:

- Small air handling units

- Exhaust fans

- Ventilation systems

Office Equipment:

- Shredders

- Printers

- Copy machines

Pumps and Compressors:

Small water pumps, oil pumps, and compressors used in homes or small industries.

Sewing Machines and Other Light Machinery:

In textiles and other small machinery, where power requirements are low.