Definition:

SF6 (Sulfur Hexafluoride) Circuit Breakers is a high-voltage electrical switchgear device that uses sulfur hexafluoride gas to protect power systems from short circuits and overloads. SF6 is a sulfur hexafluoride is used as the arc extinguishing medium. The sulfur hexafluoride gas attracts free electrons. SF6 (Sulfur Hexafluoride) Circuit Breakers are widely used in electrical power systems for high-voltage switching and protection.

Types of SF6 Circuit Breakers:

There are three distinct types of SF6 (Sulfur Hexafluoride) Circuit Breakers available. These product types include the double beam piston, non-inflating piston, and the single beam piston SF6 circuit breaker.

Double Beam Piston SF6 Circuit Breaker:

The double beam piston SF6 (Sulfur Hexafluoride) Circuit Breakers utilizes sulfur hexafluoride gas compressed in a cylinder to quench electrical arcs. During the arc extinguishing process, the gas transitions from a high-pressure state to a low-pressure state. However, the usage scope of this product is somewhat restricted when compared to other types.

2. Single Beam Piston SF6 Circuit Breaker:

The single beam piston SF6 (Sulfur Hexafluoride) Circuit Breakers is crafted with a hollow cylinder. This cylinder serves as a bridge between two contacts. The piston, integrated with the cylinder, moves between the two fixed contacts and is employed to either establish or disrupt the contact. Typically, the product is suitable for use in the voltage range of 13.6- 760 kV.

3. Non-Inflating Piston SF6 Circuit Breaker:

The non-inflating piston SF6 circuit breaker represents the initial model that was manufactured. Its operational principle can be likened to that of an air-blown circuit breaker. However, with the introduction of newer varieties of SF6 circuit breakers, the application scope of this product has diminished.

Construction of SF6 Circuit Breaker:

An SF6 circuit breaker consists of several key components:

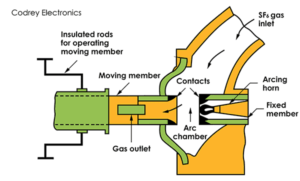

- Arc Quenching Chamber: This is the most critical part where the actual interruption of the arc takes place. The chamber is filled with SF6 gas under pressure. The arc is formed inside this chamber when contacts open and it is extinguished by the SF6 gas.

- Contacts: The breaker has fixed and moving contacts, typically made of materials such as copper or copper alloys, which allow current to flow when the breaker is closed. When a fault occurs, these contacts open, and an arc is formed.

- SF6 Gas System: SF6 gas, which has excellent dielectric and arc-quenching properties, is stored and circulated inside the breaker.The gas is maintained under pressure (typically 2 to 7 bar) inside the breaker to help quench the arc and ensure fast recovery of dielectric strength.

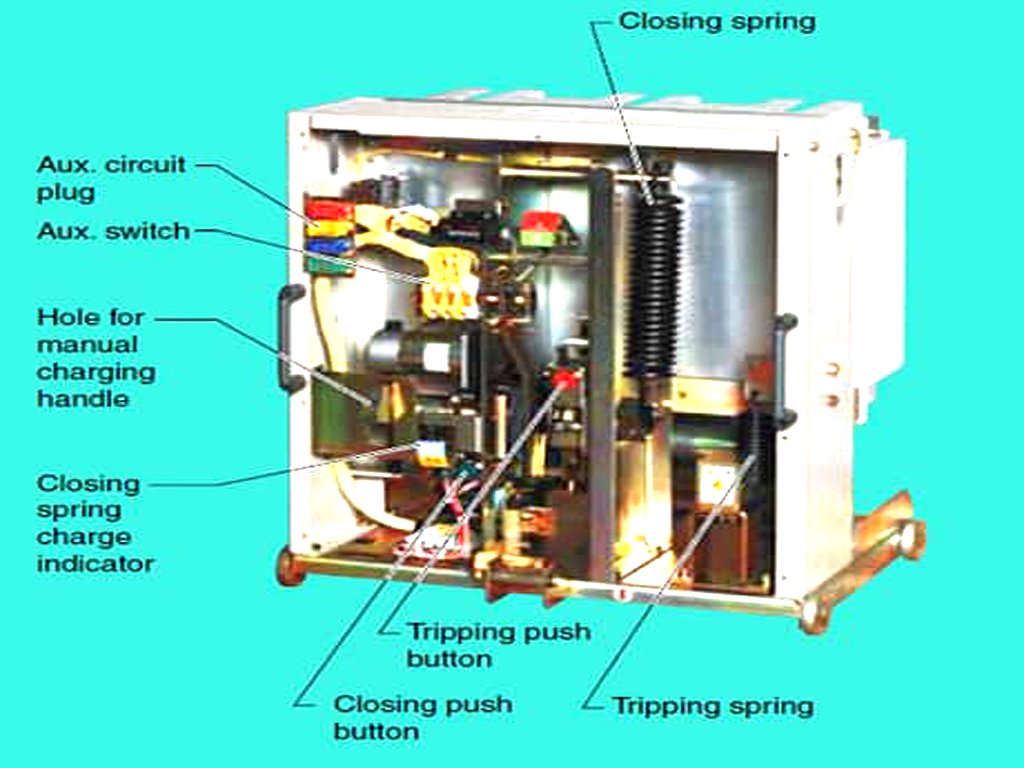

- Operating Mechanism: This system controls the opening and closing of the contacts. It can be either hydraulic, pneumatic, or spring-loaded. A spring-driven mechanism is most commonly used for its fast response time.

- Interrupter Unit: This consists of the moving contact (which is connected to a drive mechanism) and a fixed contact. The unit is designed to separate the contacts under load conditions, and the SF6 gas ensures that the arc formed between the contacts is extinguished quickly.

- Bushing and Terminal Connectors: These are used to connect the breaker to the electrical circuit.

Working Principle of SF6 Circuit Breaker:

When a fault (such as a short circuit) occurs in the electrical system, the circuit breaker detects the fault condition and initiates the process of opening the contacts. The moving contacts are mechanically operated to separate from the fixed contacts, creating an electrical arc between them. An arc is initially formed when the contacts are separated. The arc generates extreme temperatures, which can be as high as several thousand degrees Celsius.

SF6 gas has exceptional dielectric strength, and its high molecular weight helps absorb the energy from the arc. It also rapidly cools the arc and helps to break the arc. SF6 molecules undergo a process known as “electronegative behavior,” where the free electrons in the arc are captured by the SF6 molecules, neutralizing the arc and allowing the circuit to be interrupted.

After the arc is extinguished, the dielectric strength of SF6 gas rapidly recovers, allowing the circuit breaker to handle high voltages without re-establishing the arc. In some cases, the circuit breaker may automatically attempt to close again if the fault is transient. This is known as reclosing. If the fault persists, the breaker will remain open.

Applications of SF6 Circuit Breakers:

SF6 (Sulfur Hexafluoride) Circuit Breakers are used in various high-voltage applications due to their excellent insulating and arc-quenching properties:

- Power Transmission Networks: SF6 (Sulfur Hexafluoride) Circuit Breakers are widely used in power transmission networks for high-voltage substations (typically 72.5 kV and above). They protect transmission lines, transformers, and other critical components from faults.

- Electrical Distribution Systems: In medium-voltage systems (up to 36 kV), SF6 (Sulfur Hexafluoride) Circuit Breakers are used to protect distribution circuits in industrial plants, residential areas, and commercial buildings.

- Gas-insulated Switchgear (GIS): SF6 circuit breakers are integral components of gas-insulated switchgear systems, which are compact, require less maintenance, and are used in environments with limited space, such as underground or in urban areas.

- Renewable Energy Applications: SF6 circuit breakers are increasingly used in renewable energy systems, such as wind farms and solar power plants, to ensure protection against electrical faults.

- Railway Electrification: SF6 (Sulfur Hexafluoride) Circuit Breakers are also used in the railway industry for electrification systems to protect against faults in high-voltage circuits.

- Large Industrial Plants: In industrial plants with complex electrical systems and large electrical loads, SF6 breakers are used for protecting motors, generators, and other high-voltage equipment.

Advantages of SF6 Circuit Breakers:

- Excellent Arc Quenching: SF6 has superior arc-quenching properties, which allows for quick interruption of electrical arcs.

- High Dielectric Strength: SF6 gas has a higher dielectric strength compared to air, making it ideal for high-voltage applications. The dielectric strength of SF6 gas is 2 to 3 times that of air and can interrupt much larger currents.

- Compact Design: SF6 (Sulfur Hexafluoride) Circuit Breakers , especially in GIS systems, have a compact design and can be installed in space-constrained areas.

- Low Maintenance: SF6 circuit breakers generally require less maintenance compared to oil or air circuit breakers. Low maintenance cost

- There is no risk of fire as it is non-inflammable

- The gas has good insulating properties

- Less arcing time

- Noiseless operations

- Suitable for outdoor installation.

Disadvantages of SF6 Circuit Breakers:

- Environmental Impact: SF6 (Sulfur Hexafluoride) Circuit Breakers is a potent greenhouse gas, and its leakage into the atmosphere can contribute to climate change. Proper handling and disposal are critical to mitigate environmental impact.

- Cost: SF6 (Sulfur Hexafluoride) Circuit Breakers can be more expensive than other types of breakers, especially in terms of initial installation and maintenance.

- Needs cleaning periodically

- Re-condition of the SF6 gas after every operation

Conclusion

SF6 circuit breakers are essential for the protection and control of high-voltage power systems, offering reliable performance with excellent arc-quenching capabilities. Despite the environmental concerns associated with SF6, their widespread use in power transmission, industrial, and renewable energy applications highlights their importance in modern electrical systems.