Introduction to SCADA Systems

SCADA, which stands for Supervisory Control and Data Acquisition, is an advanced industrial control system used to monitor, control and analyze industrial processes in real time. SCADA systems are widely implemented in sectors such as power generation and distribution, water treatment, oil and gas pipelines, manufacturing plants, transportation systems and smart cities.

The primary purpose of a SCADA system is to enable operators to supervise large-scale and geographically distributed processes from a centralized location. By collecting real-time data from field devices and providing control commands remotely, SCADA systems improve operational efficiency, safety, reliability and decision-making. With the integration of modern communication networks and cyber security measures, SCADA has evolved into a critical component of industrial automation and digital transformation.

How It Works?

SCADA (Supervisory Control and Data Acquisition) is a system used to monitor, supervise, and control industrial processes from a centralized location. SCADA systems collect real-time data from field devices such as PLCs, sensors and Remote Terminal Units (RTUs) and display this data to operators through graphical interfaces.

The working of a SCADA system involves four main steps:

- Data collection from field devices

- Data communication through wired or wireless networks

- Data processing and storage in central servers

- Data visualization and control through Human Machine Interfaces (HMI)

For diploma learners, SCADA can be seen as a system that shows machine status on a computer screen. For BSc students, SCADA includes system architecture, communication protocols, databases, and alarm management.

SCADA systems allow operators to monitor large and geographically distributed processes such as power grids, water distribution networks, oil pipelines, and industrial plants. By providing real-time visibility and remote control, SCADA systems improve efficiency, safety, and operational awareness.

Importance of PLC and SCADA in Modern Industry

The importance of PLC and SCADA systems in modern industry cannot be overstated. As industries grow in size and complexity, manual control becomes inefficient, unsafe and prone to errors. PLC and SCADA systems enable automation, centralization, and intelligent control.

PLCs ensure precise and fast control of machines, reducing production errors and improving product quality. SCADA systems provide real-time monitoring, historical data analysis and centralized supervision, enabling better decision-making.

For diploma students, PLC and SCADA reduce manual work and improve safety. For BSc students, these systems support advanced automation strategies, optimization and integration with digital technologies.

Industries such as manufacturing, power generation, oil and gas, water treatment, transportation, and smart infrastructure rely heavily on PLC and SCADA systems. These technologies also support modern concepts like Industry 4.0, smart factories, and energy management, making them essential tools in today’s industrial environment.

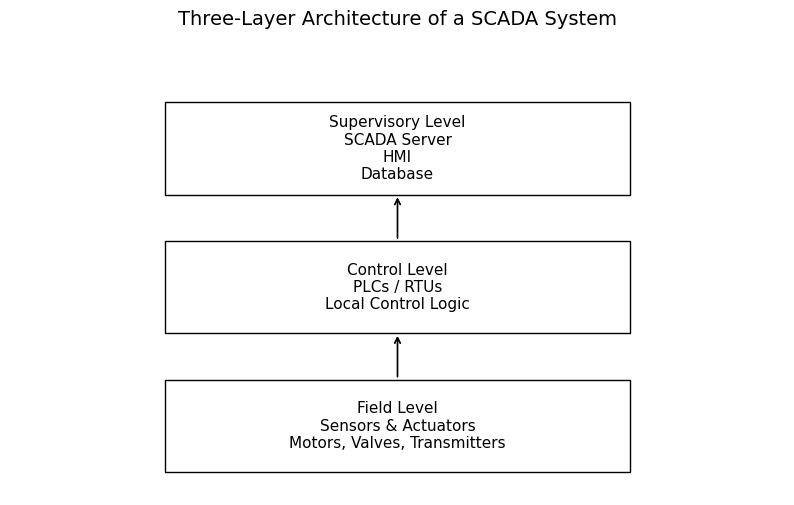

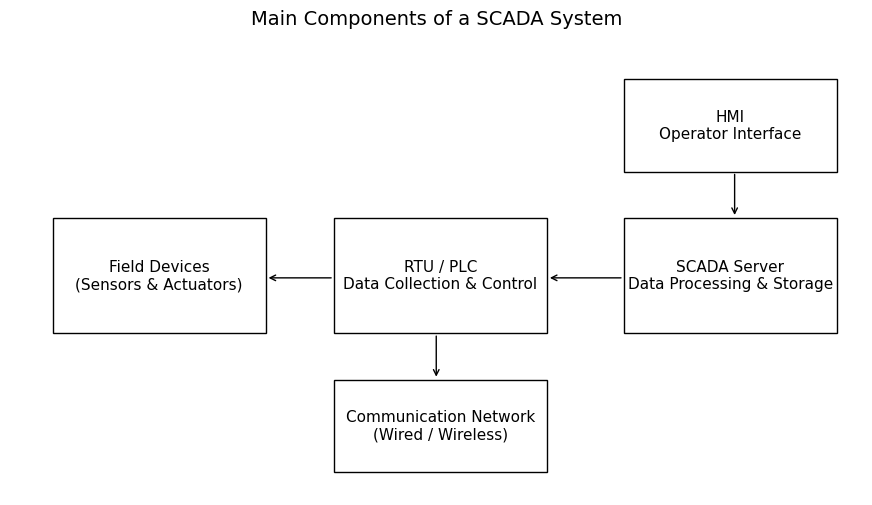

Architecture of a SCADA System

The architecture of a SCADA system defines how it’s hardware and software components interact to ensure seamless monitoring and control. Typically, SCADA architecture is organized into three main layers:

Field Level:

Description

The Field Level is the lowest layer of the SCADA architecture. It consists of physical devices that directly interact with the industrial process.

Main Components

- Sensors (temperature, pressure, flow, level)

- Actuators (motors, valves, pumps)

- Transmitters and switches

Function

- Sensors measure real-world physical parameters.

- Actuators perform physical actions based on control commands.

- Raw process data is generated at this level and sent to the control level.

Key Point

Field level is responsible for data generation and physical process execution.

Control Level

Description

The Control Level acts as the brain of local automation. It processes data received from the field level and makes immediate control decisions.

Main Components

- Programmable Logic Controllers (PLCs)

- Remote Terminal Units (RTUs)

- Local control panels

Function

- Receives signals from sensors

- Executes control logic and automation programs

- Sends control commands to actuators

- Communicates process data to the supervisory level

Key Point

Control level performs real-time decision-making and local control.

Supervisory Level

Description

The Supervisory Level is the top layer of the SCADA system. It provides centralized monitoring, visualization and data management.

Main Components

- SCADA servers

- Human Machine Interface (HMI)

- Databases and historian servers

Function

- Displays real-time process data on graphical screens

- Allows operators to control the process remotely

- Stores historical data for analysis and reporting

- Generates alarms and system notifications

Key Point:

Supervisory level enables monitoring, supervision and decision support.

Data Flow in SCADA Architecture

- Upward flow:

Field Level → Control Level → Supervisory Level (process data) - Downward flow:

Supervisory Level → Control Level → Field Level (control commands)

This bidirectional flow ensures continuous monitoring and efficient control.

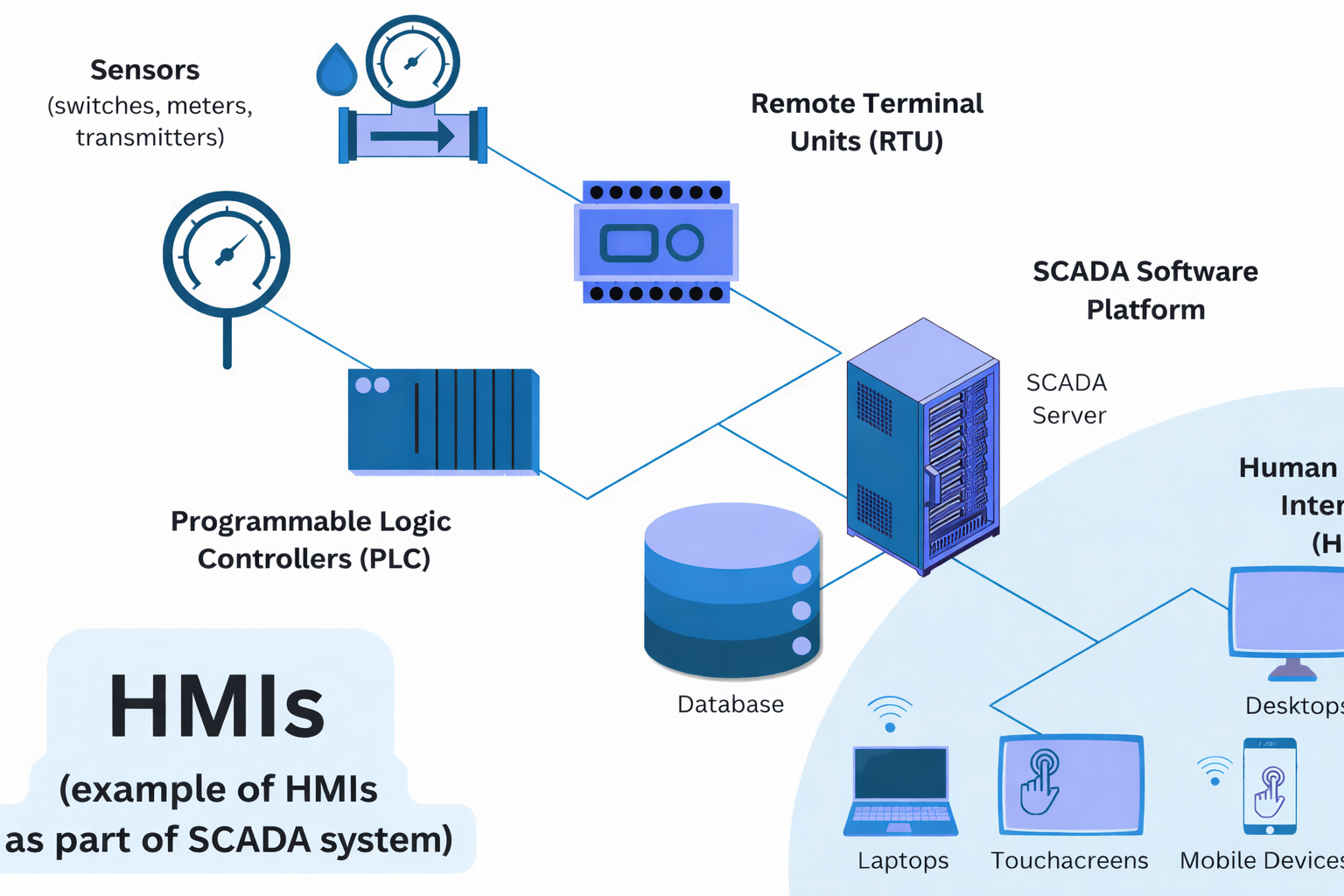

Components of SCADA Systems

A SCADA system is composed of several essential components that work together to provide reliable supervision and control.

Field Devices (Sensors and Actuators)

Explanation

Field devices are installed directly on the industrial process.

Sensors measure physical parameters such as:

- Temperature

- Pressure

- Flow

- Level

- Voltage

Actuators perform actions such as:

- Starting motors

- Opening or closing valves

- Switching relays

Key Point

Field devices collect real-world data and execute physical actions.

RTU / PLC (Remote Terminal Unit / Programmable Logic Controller)

Remote Terminal Units (RTUs)

RTUs are microprocessor-based devices installed at remote sites. They interface with sensors and actuators to collect field data. RTUs are designed to operate in harsh environmental conditions and often support multiple communication protocols. They send acquired data to the SCADA master station and receive control instructions in return.

Programmable Logic Controllers (PLCs)

PLCs are specialized industrial computers used primarily for local automation and control. Unlike RTUs, PLCs are optimized for high-speed logic execution and are commonly used in manufacturing and process industries. In SCADA systems, PLCs act as intelligent field controllers that communicate with supervisory software.

RTUs and PLCs act as the control units of the SCADA system.

Functions:

- Receive signals from sensors

- Process data using control logic

- Send commands to actuators

- Communicate data to the SCADA server

Key Point

👉 RTU/PLC performs local control and data acquisition.

Communication Network:

The communication network connects field devices to the SCADA master station. It can be based on wired (Ethernet, fiber optics) or wireless (radio, cellular, satellite) technologies. Common protocols include Modbus, DNP3, IEC 60870 and OPC. Reliable communication is crucial for real-time monitoring and system integrity.

Explanation

The communication network transfers data between field devices, RTUs/PLCs and the SCADA server.

Types:

- Wired: Ethernet, Fiber Optic, Serial

- Wireless: Radio, Cellular, Satellite

Common protocols:

- Modbus

- DNP3

- Profibus

- Ethernet/IP

Key Point

👉 Communication network ensures reliable data transfer.

SCADA Server

The SCADA server is the central processing unit of the system.

Functions:

- Receives real-time data from PLCs/RTUs

- Processes and stores data in databases

- Generates alarms and reports

- Sends control commands back to PLCs

Key Point

👉 SCADA server handles data processing, storage, and supervision.

HMI (Human Machine Interface)

The HMI is the graphical interface through which operators interact with the SCADA system. It displays real-time data using graphs, alarms, dashboards and mimic diagrams. HMIs allow operators to issue control commands, acknowledge alarms and analyze trends for informed decision-making.

HMI is the graphical interface used by operators.

Functions:

- Displays live system status

- Shows alarms and warnings

- Allows operators to control processes

- Displays trends and reports

Examples:

- Control room screens

- Touch panels

- Web-based dashboards

Key Point

👉 HMI allows human interaction with the SCADA system.

Data Flow in SCADA Components

- Upward Flow:

Sensors → RTU/PLC → SCADA Server → HMI - Downward Flow:

HMI → SCADA Server → RTU/PLC → Actuators

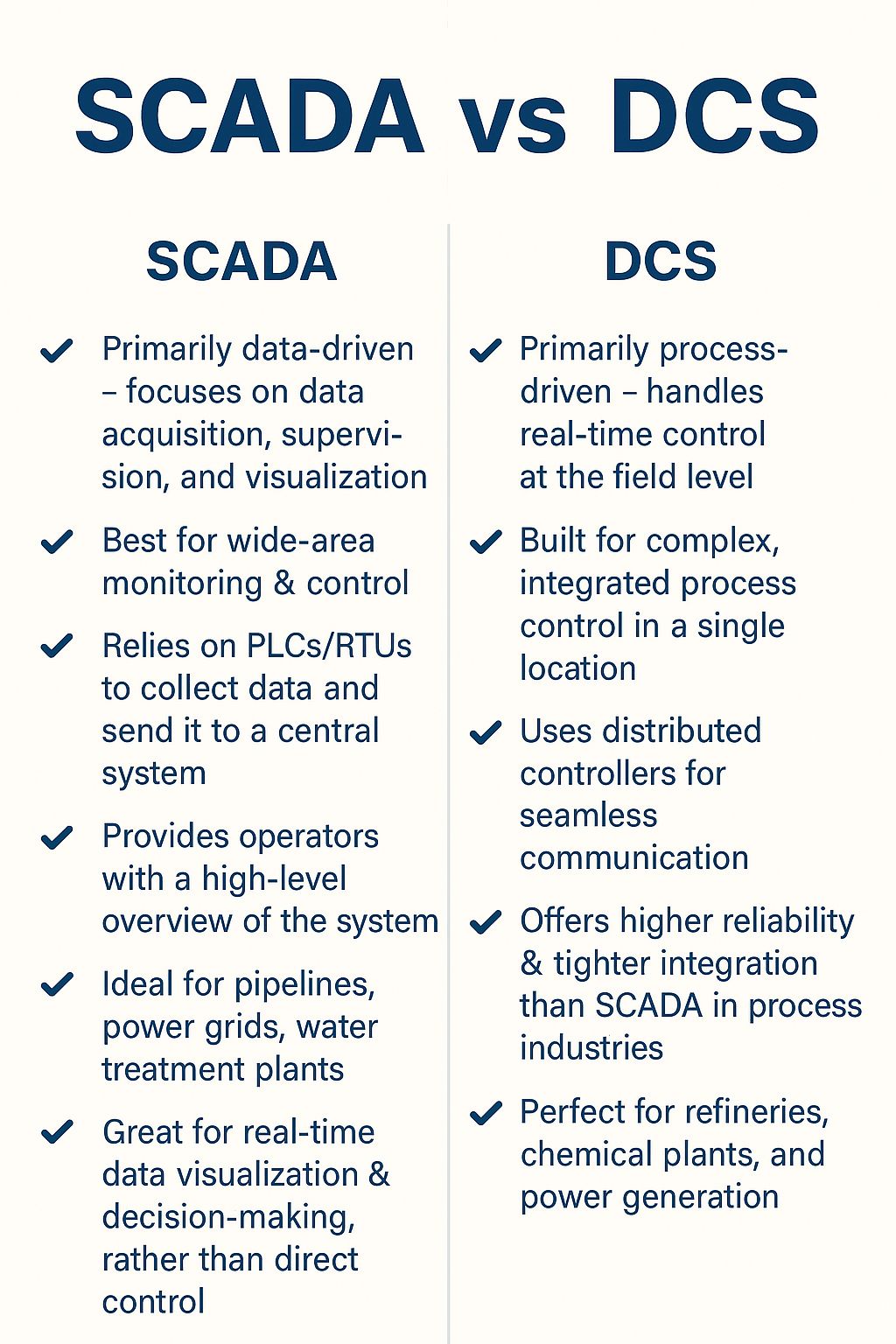

SCADA vs DCS: A Comparative Study

SCADA and Distributed Control Systems (DCS) are both industrial control systems but they differ in design and application.

SCADA systems are mainly used for large-scale, geographically dispersed operations such as pipelines or power grids. They focus on supervisory control rather than continuous process control. SCADA relies heavily on communication networks and remote monitoring.

In contrast, DCS systems are typically implemented within a single plant or facility, such as chemical or pharmaceutical plants. DCS provides tighter control loops and faster response times, making it ideal for continuous processes.

While SCADA emphasizes data acquisition and centralized supervision, DCS prioritizes real-time process control and automation. In modern industries, hybrid systems combining SCADA and DCS features are increasingly common.

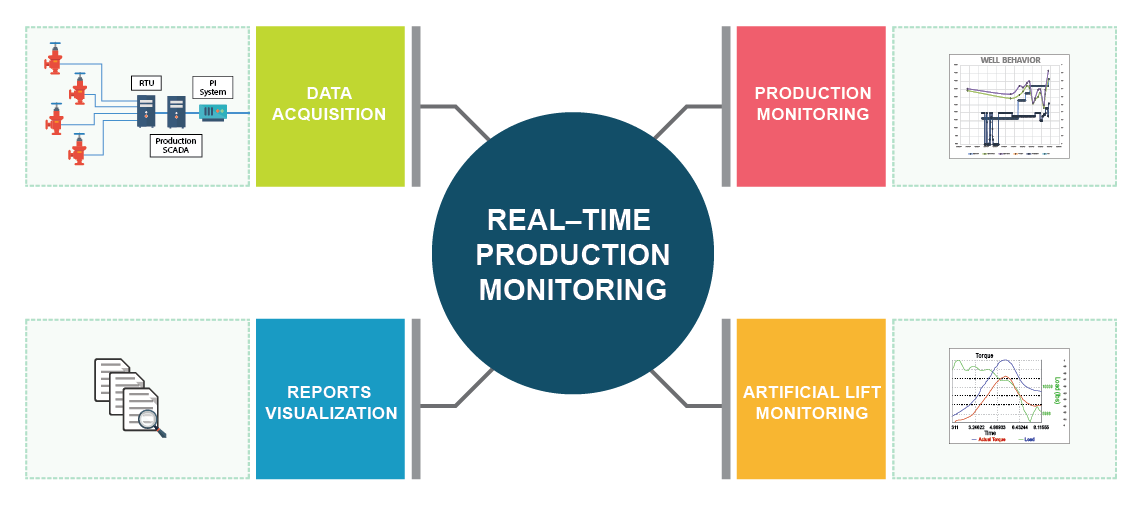

Data Acquisition in SCADA Systems

Data acquisition is the core function of any SCADA system. It involves the systematic collection, processing and transmission of data from field devices to the supervisory system.

Sensors continuously measure physical parameters and convert them into electrical signals. These signals are captured by RTUs or PLCs, which digitize the data and perform initial processing such as filtering or scaling. The processed data is then transmitted to the SCADA master station through communication networks.

Once received, the SCADA software stores the data in databases for real-time monitoring, historical analysis, and reporting. Alarms systems are triggered if predefined thresholds are exceeded, allowing operators to respond quickly to abnormal conditions.

Effective data acquisition enables predictive maintenance, fault detection, performance optimization, and regulatory compliance, making it a vital element of modern industrial operations.

SCADA systems play a crucial role in today’s industrial and infrastructure environments by enabling real-time supervision, control, and data-driven decision-making. Through a well-defined architecture and integrated components such as RTUs, PLCs, HMIs, and communication networks, SCADA systems ensure reliable and efficient operation of complex processes. Understanding the differences between SCADA and DCS, along with the importance of data acquisition, provides a strong foundation for engineers and students working in automation and control fields. As industries continue to adopt digital technologies, SCADA systems will remain a cornerstone of industrial automation and smart infrastructure.

SCADA Operation and Design in Industrial Automation

Supervisory Control and Data Acquisition (SCADA) systems play a vital role in modern industrial automation by enabling efficient monitoring, control and analysis of industrial processes. SCADA operation focuses on how data is collected, displayed, analyzed and used to control real-time processes, while SCADA design emphasizes usability, reliability and safety. This article discusses key aspects of SCADA operation and design, including Human Machine Interface (HMI) design, real-time monitoring, industrial process control, alarm management and data logging with historical analysis. Together, these functions allow industries to operate complex systems with accuracy, speed, and minimal human error.

Human Machine Interface (HMI) Design in SCADA

The Human Machine Interface (HMI) is the visual and interactive component of a SCADA system. It allows operators to observe system conditions, receive alerts and issue control commands. A well-designed HMI is critical because it directly affects operator efficiency, safety, and decision-making.

Effective HMI design follows principles such as simplicity, clarity, consistency, and usability. Screens should avoid unnecessary graphics and focus on meaningful information. Color usage must be standardized—normal conditions are usually displayed in neutral colors, while abnormal conditions are highlighted using warning colors like yellow or red.

For diploma-level users, HMIs provide intuitive graphical representations such as tanks, motors, valves, and pipelines. For BSc-level applications, HMIs may also include trend charts, diagnostic tools and performance indicators. Touchscreen support, scalable displays and role-based access control are common features in modern HMI design.

A well-designed HMI reduces operator fatigue, minimizes errors and improves response time during abnormal situations, making it a core element of SCADA operation.

Real-Time Monitoring Using SCADA

Real-time monitoring is one of the most important functions of a SCADA system. It allows operators to continuously observe industrial processes as they occur. Sensors installed in the field measure physical parameters such as temperature, pressure, flow rate, voltage and speed. These values are transmitted to the SCADA system through RTUs or PLCs.

SCADA software updates this information in real time on the HMI screens, allowing operators to detect changes instantly. Real-time monitoring helps in identifying abnormal conditions, equipment failures, or process deviations before they lead to serious problems.

For diploma-level understanding, real-time monitoring means watching live system values on a screen. At the BSc level, it involves understanding scan rates, communication delays, data validation and system latency. Advanced SCADA systems may also use predictive analytics to forecast potential failures based on real-time trends.

Overall, real-time monitoring improves operational safety, reduces downtime and supports quick decision-making in industrial environments.

SCADA for Industrial Process Control

SCADA systems are widely used for industrial process control in sectors such as manufacturing, power generation, oil and gas, water treatment and transportation. While SCADA does not usually perform high-speed control loops directly, it supervises and coordinates control actions carried out by PLCs and RTUs.

In industrial process control, SCADA allows operators to start or stop equipment, adjust setpoints and switch operating modes remotely. This centralized control reduces the need for manual intervention at field locations, especially in large or hazardous environments.

For diploma students, SCADA process control can be understood as remote operation of machines. For BSc students, it involves understanding control hierarchies, feedback loops, interlocks and system integration. SCADA also supports batch processing, sequence control, and optimization strategies in complex industrial systems.

By integrating monitoring and control functions, SCADA systems improve process efficiency, product quality and operational consistency.

Alarm Management in SCADA Systems

Alarm management is a critical safety and reliability feature of SCADA systems. Alarms notify operators when process variables exceed predefined limits or when equipment malfunctions occur. Without proper alarm management, operators may experience alarm flooding, leading to confusion and delayed responses.

A well-designed alarm system prioritizes alarms based on severity. Critical alarms require immediate action, while warning alarms indicate conditions that may become serious if ignored. Informational alarms are used for logging purposes only.

For diploma-level learning, alarm management focuses on recognizing alarms and responding correctly. At the BSc level, it includes alarm rationalization, deadband settings, shelving and alarm performance metrics.

Modern SCADA systems follow international standards for alarm management to ensure clarity and effectiveness. Proper alarm handling improves plant safety, reduces accidents and enhances operational awareness.

Data Logging and Historical Data Analysis

Data logging is the process of recording operational data over time. SCADA systems store real-time data in databases, creating historical records that can be analyzed later. This function is essential for performance evaluation, troubleshooting, compliance reporting, and future planning.

Historical data analysis allows engineers and operators to study trends, identify recurring issues, and optimize processes. For example, analyzing temperature trends may reveal equipment inefficiencies or maintenance needs.

Diploma students typically use historical data for basic reporting and trend viewing. BSc students analyze data statistically, perform root cause analysis and apply predictive maintenance techniques.

Advanced SCADA systems integrate data logging with cloud platforms and analytics tools, enabling long-term storage and deeper insights. This makes historical data a valuable asset for continuous improvement and smart industrial operations.

SCADA operation and design form the backbone of modern industrial automation systems. Through effective HMI design, real-time monitoring, industrial process control, alarm management and data logging, SCADA systems enable safe, efficient and intelligent operation of complex processes. The concepts discussed in this article are suitable for both diploma and BSc students, providing a strong foundation for understanding industrial control systems. As industries continue to adopt digital and smart technologies, the importance of well-designed and properly operated SCADA systems will continue to grow.

Advanced and Modern Applications of SCADA Systems

Supervisory Control and Data Acquisition (SCADA) systems have evolved significantly with the advancement of information technology, communication networks and industrial automation. Traditional SCADA systems were mainly limited to local control rooms and proprietary hardware. However, modern SCADA systems now integrate web technologies, cloud computing, cyber security frameworks and smart infrastructure applications. These advancements have expanded the role of SCADA beyond basic monitoring and control into intelligent, scalable and secure industrial management systems. This article discusses advanced and modern SCADA topics, including web-based SCADA, cyber security challenges, cloud-based solutions, smart grid applications, water treatment systems and reliability with redundancy.

Web-Based SCADA Systems

Web-based SCADA systems represent a major shift from conventional desktop-based SCADA software. In web-based SCADA, system data and graphical interfaces are accessed through web browsers using standard internet technologies. This allows operators, engineers and managers to monitor industrial processes remotely without the need for specialized software installations.

For diploma-level understanding, web-based SCADA can be seen as viewing plant data through a secure webpage. For BSc students, it involves concepts such as client-server architecture, web protocols, real-time data rendering and secure authentication mechanisms.

Web-based SCADA improves accessibility, reduces maintenance costs and supports multi-user collaboration. However, it also introduces challenges related to network performance and security, which must be addressed through proper system design and access control.

SCADA Cyber security Challenges

As SCADA systems become more connected to corporate networks and the internet, cyber security has become a critical concern. Cyber threats such as malware, ransomware, unauthorized access and data manipulation can disrupt industrial operations and cause serious safety and economic consequences.

Traditional SCADA systems were designed with minimal security, assuming physical isolation. Modern systems, however, require strong cybersecurity strategies. These include firewalls, intrusion detection systems, encryption, secure communication protocols and regular system updates.

For diploma students, cyber security focuses on understanding threats and basic protection methods such as passwords and access levels. BSc-level learning includes risk assessment, network segmentation, security policies and compliance with international cyber security standards.

Addressing cybersecurity challenges is essential to ensure the safe and reliable operation of modern SCADA systems in connected environments.

Cloud-Based SCADA Solutions

Cloud-based SCADA solutions use cloud computing platforms to store, process and analyze industrial data. Instead of relying solely on on-site servers, data is transmitted securely to cloud infrastructure where advanced analytics and storage services are available.

For diploma learners, cloud-based SCADA means accessing system data from anywhere using secure internet connections. For BSc students, it involves understanding cloud architectures, virtualization, data synchronization, and latency management.

Cloud-based SCADA offers benefits such as scalability, reduced hardware costs, remote access, and integration with artificial intelligence and machine learning tools. However, challenges such as data privacy, communication delays, and dependency on internet connectivity must be carefully managed.

Cloud integration has transformed SCADA systems into powerful platforms for data-driven decision-making and industrial intelligence.

SCADA in Smart Grid Applications

Smart grids use digital technologies to improve the efficiency, reliability and sustainability of electrical power systems. SCADA plays a central role in smart grid operation by enabling real-time monitoring and control of power generation, transmission and distribution networks.

In smart grid applications, SCADA systems collect data from substations, transformers, smart meters, and renewable energy sources. This data helps operators balance load demand, detect faults and manage power quality.

For diploma students, SCADA in smart grids involves monitoring voltage and power flow. At the BSc level, it includes advanced topics such as distributed energy resources, automated fault isolation and grid optimization.

SCADA integration in smart grids supports renewable energy integration, reduces outages and enhances energy efficiency, making it a key technology for modern power systems.

SCADA for Water Treatment Plants

Water treatment plants rely heavily on SCADA systems to ensure safe, efficient, and continuous water supply. SCADA monitors parameters such as water level, flow rate, pressure, chemical dosage and water quality indicators.

For diploma-level understanding, SCADA allows operators to control pumps, valves and treatment processes remotely. For BSc students, it includes process modeling, control strategies, and compliance with environmental regulations.

SCADA systems help detect leaks, prevent overflows, and optimize chemical usage. Alarm systems alert operators to abnormal conditions, ensuring quick corrective actions.

By improving operational efficiency and safety, SCADA systems play a crucial role in protecting public health and managing water resources effectively.

SCADA System Reliability and Redundancy

Reliability is a critical requirement for SCADA systems, especially in industries where downtime can lead to safety hazards or financial losses. Modern SCADA systems are designed with redundancy to ensure continuous operation even in the event of component failure.

Redundancy may be implemented at various levels, including servers, communication networks, power supplies, and data storage. Backup systems automatically take over when a primary system fails, minimizing downtime.

For diploma students, reliability means system availability. For BSc students, it involves fault tolerance, failover mechanisms, system testing, and reliability analysis.

High system reliability ensures uninterrupted monitoring and control, making redundancy a vital design consideration in advanced SCADA systems.

Modern SCADA systems have evolved into advanced, intelligent platforms that support remote access, cyber security, cloud computing and smart infrastructure applications. Web-based SCADA improves accessibility, cloud solutions enhance scalability and cyber security ensures system protection. Applications in smart grids and water treatment plants highlight the importance of SCADA in critical infrastructure. Finally, system reliability and redundancy ensure continuous and safe operation. Understanding these advanced SCADA concepts provides both diploma and BSc students with essential knowledge for working in modern industrial automation and control systems.

PLC and SCADA Integration in Modern Industrial Automation

Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems are the backbone of modern industrial automation. While PLCs are responsible for real-time control of machines and processes, SCADA systems provide supervision, monitoring, data acquisition and centralized control. When integrated together, PLC and SCADA systems create a powerful automation solution that improves productivity, reliability, efficiency and decision-making across industries. This article discusses the integration of PLC and SCADA systems, their communication architecture, applications in industrial automation, role in Industry 4.0, a manufacturing plant case study and their use in energy management systems.

Integration of PLC and SCADA Systems

The integration of PLC and SCADA systems allows seamless interaction between field-level control and supervisory-level monitoring. PLCs control machines by executing programmed logic based on sensor inputs, while SCADA systems collect data from PLCs and present it to operators through graphical interfaces.

For diploma-level understanding, integration means connecting PLCs to a SCADA screen so operators can monitor and control machines remotely. At the BSc level, integration includes system configuration, tag mapping, data synchronization, and performance optimization.

Integrated PLC–SCADA systems reduce manual intervention, improve response time, and provide centralized control of distributed processes. This integration is essential in large industrial plants where multiple PLCs operate simultaneously under one SCADA platform.

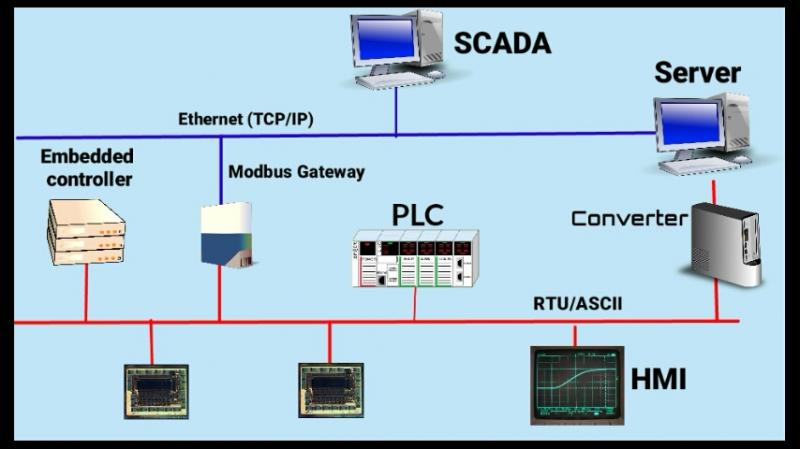

PLC–SCADA Communication Architecture

Communication architecture defines how PLCs and SCADA systems exchange data. Typically, PLCs are connected to sensors and actuators at the field level, while SCADA software operates at the supervisory level. Data flows from PLCs to SCADA systems for monitoring and control commands flow from SCADA back to PLCs.

Common communication methods include Ethernet, serial communication, and industrial networks. Standard protocols such as Modbus, Profibus, Profinet, Ethernet/IP and OPC are widely used.

For diploma students, this architecture can be visualized as PLCs sending data to a computer screen. For BSc students, it involves understanding network topology, communication latency, protocol selection and data integrity.

A well-designed communication architecture ensures reliable data transfer, minimal delays and secure operation, which are crucial for real-time industrial control.

Industrial Automation Using PLC and SCADA

Industrial automation using PLC and SCADA systems replaces manual control with automated, intelligent processes. PLCs handle fast and precise control actions such as motor starting, valve operation, and safety interlocks. SCADA systems supervise these actions, collect data and provide centralized monitoring.

In industries such as manufacturing, oil and gas, water treatment, power plants and food processing, PLC–SCADA automation improves consistency, reduces human error and enhances safety.

Diploma students focus on operating automated systems and understanding basic logic. BSc students analyze automation strategies, system optimization, and integration with other enterprise systems.

Together, PLC and SCADA systems enable industries to achieve higher productivity, reduced downtime, and improved quality control.

Role of PLC and SCADA in Industry 4.0

Industry 4.0 represents the fourth industrial revolution, characterized by smart factories, digitalization and interconnected systems. PLC and SCADA systems play a vital role in this transformation by acting as the foundation of industrial data collection and control.

Modern PLCs support advanced communication, data processing and connectivity with cloud platforms. SCADA systems integrate real-time data with analytics, dashboards and remote monitoring.

For diploma students, Industry 4.0 means smarter machines and digital monitoring. For BSc students, it includes concepts such as Industrial Internet of Things (IIoT), big data analytics, cybersecurity and predictive maintenance.

By enabling real-time data visibility and intelligent control, PLC and SCADA systems support smart manufacturing, flexible production, and data-driven decision-making in Industry 4.0 environments.

Case Study: PLC and SCADA in a Manufacturing Plant

Consider a medium-scale manufacturing plant producing consumer goods. The plant uses multiple machines such as conveyors, mixers, packaging units and robotic arms. Each machine is controlled by a PLC programmed to handle specific tasks.

All PLCs are connected to a central SCADA system through an industrial Ethernet network. The SCADA system displays machine status, production counts, fault conditions and energy consumption on HMI screens in the control room.

Operators can start or stop machines, adjust set points and respond to alarms from a single location. Maintenance engineers analyze historical data to identify recurring faults and schedule preventive maintenance.

This PLC–SCADA integration improves production efficiency, reduces downtime, enhances safety and provides management with real-time production insights.

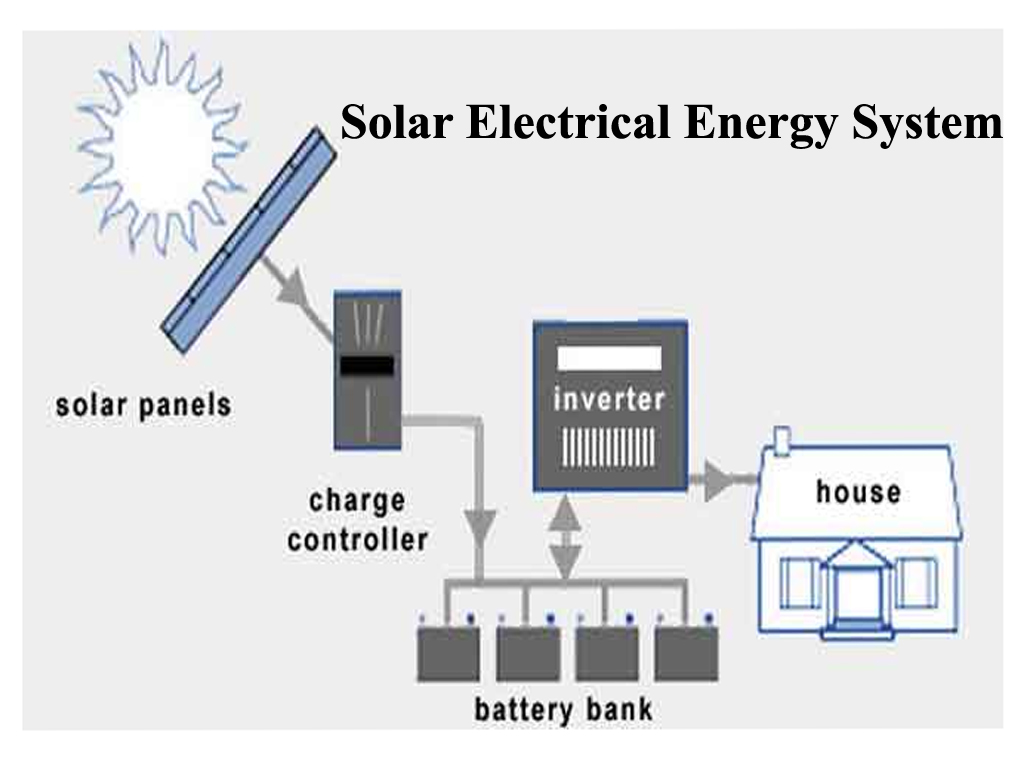

PLC and SCADA for Energy Management Systems

Energy management has become a critical concern due to rising energy costs and environmental regulations. PLC and SCADA systems are widely used to monitor, control and optimize energy usage in industrial and commercial facilities.

PLCs collect data from energy meters, sensors, and equipment such as motors, compressors and lighting systems. SCADA systems analyze this data and display energy consumption patterns, peak demand and efficiency indicators.

For diploma students, this involves monitoring energy usage. For BSc students, it includes load optimization, demand response strategies and integration with renewable energy sources.

PLC and SCADA-based energy management systems help industries reduce energy waste, lower operational costs and achieve sustainability goals.

The integration of PLC and SCADA systems forms the core of modern industrial automation. PLCs provide fast and reliable control, while SCADA systems offer supervision, visualization, and data analysis. Together, they enable efficient automation, support Industry 4.0 initiatives, improve manufacturing operations, and optimize energy management. Understanding PLC–SCADA integration, communication architecture, and real-world applications provides diploma and BSc students with essential skills for careers in industrial automation and control engineering. As industries continue to evolve, the importance of PLC and SCADA systems will continue to grow.

Introduction to PLC and SCADA Systems in Modern Industry

Automation has become an essential part of modern industry, enabling faster production, improved quality and safer working environments. Two of the most important technologies behind industrial automation are Programmable Logic Controllers (PLC) and Supervisory Control and Data Acquisition (SCADA) systems. PLCs perform control operations at the machine level, while SCADA systems provide monitoring, supervision, and data management at a higher level. Together, PLC and SCADA systems form the foundation of automated industrial operations. This article introduces PLC and SCADA in a beginner-friendly manner, explaining their functions, working principles, importance in modern industry, and their advantages and limitations.

What Is PLC and Why It Is Used?

A Programmable Logic Controller (PLC) is a specialized industrial computer designed to control machines and processes automatically. Unlike ordinary computers, PLCs are built to operate reliably in harsh industrial environments that may include high temperatures, dust, vibrations and electrical noise.

A PLC works by continuously scanning input signals from field devices such as sensors, switches and push buttons. Based on a pre-written control program, the PLC processes these inputs and generates output signals to control actuators such as motors, valves, relays and alarms.

For diploma students, a PLC can be understood as an electronic replacement for relay-based control panels. For BSc students, PLCs involve concepts such as scan cycles, memory organization, ladder logic and real-time control.

PLCs are widely used because they are flexible, reliable, easy to program and simple to maintain. If a control sequence needs to be changed, engineers can modify the PLC program without rewiring hardware. This makes PLCs ideal for industrial applications such as manufacturing lines, conveyor systems, elevators and packaging machines.

Advantages of PLC and SCADA

PLC and SCADA systems offer several advantages that make them indispensable in industrial automation.

One major advantage is improved efficiency. Automated systems operate continuously with minimal human intervention, increasing production speed and consistency.

Another advantage is enhanced safety. PLCs handle safety interlocks and emergency shutdowns, while SCADA systems provide alarms and warnings for abnormal conditions.

PLC and SCADA systems also offer flexibility and scalability. New machines, sensors, or control logic can be added without major system redesign.

Additionally, SCADA systems provide data logging and analysis, helping industries identify faults, optimize performance, and plan maintenance activities.

For both diploma and BSc students, understanding these advantages highlights why automation is essential for modern industrial growth.

Limitations of PLC and SCADA

Despite their many benefits, PLC and SCADA systems also have certain limitations. One limitation is initial cost, as hardware, software, and system integration can be expensive, especially for small industries.

Another limitation is cyber security risk. As SCADA systems become connected to networks and the internet, they become vulnerable to cyber threats if not properly protected.

PLC systems may also face limitations in handling extremely complex data processing compared to general-purpose computers. Additionally, SCADA systems depend on reliable communication networks; failures can affect monitoring and control.

For diploma students, these limitations emphasize the need for proper operation and maintenance. For BSc students, they highlight the importance of system design, cyber security, and reliability engineering.

PLC and SCADA systems are fundamental technologies in modern industrial automation. PLCs provide reliable and fast machine control, while SCADA systems enable supervision, monitoring and data management. Together, they improve efficiency, safety and productivity across various industries. Understanding what PLC and SCADA are, how they work, their importance and their advantages and limitations provides a strong foundation for both diploma and BSc students. As industries continue to evolve toward digital and smart systems, knowledge of PLC and SCADA will remain essential for future engineers and technicians.