What is Lightning Arrester?

A lightning arrester is a device used in electrical systems to protect buildings, electrical equipment, and power lines from the damaging effects of lightning strikes. A Lightning Arrester (LA), also known as a Surge Arrester or Surge Diverter. A lightning arrester provides a low-resistance path to the ground for lightning or high-voltage surges. It diverts the surge away from the protected equipment and safely dissipates it into the earth. After the surge, the arrester returns to its normal state and allows regular voltage to continue flowing.

Where it’s used:

- Power transmission and distribution systems

- Transformers and substations

- Telecommunications equipment

- Homes and commercial buildings (surge protectors are a type of low-power arrester)

How a Lightning Arrester Works:

- Connected in Parallel: A lightning arrester is always connected in parallel (across) the equipment it’s protecting, typically between the live (phase) conductor and the ground.

- High Resistance under Normal Conditions: Under normal operating conditions (i.e., at the system’s rated voltage), the lightning arrester presents a very high impedance (resistance). This prevents any significant current from flowing through it to the ground, allowing the normal power current to flow to the load.

- Low Resistance during Overvoltage: When a high-voltage surge (like from a lightning strike or a switching operation) travels along the line, the voltage across the arrester’s terminals rapidly increases. At a predetermined “breakdown” or “sparkover” voltage, the arrester’s internal resistance suddenly drops to a very low value.

- Diverting the Surge: This low-resistance path provides an easy and immediate route for the high-voltage surge current to flow directly to the ground, bypassing the protected equipment. This limits the voltage rise across the equipment to a safe level.

- Restoring to Normal: Once the surge current has been safely discharged to the ground and the voltage on the line returns to its normal operating level, the arrester’s resistance automatically reverts to its high-impedance state, effectively “resealing” the path to ground and allowing normal power flow to resume.

Key Purpose and Benefits:

- Equipment Protection: Prevents damage to expensive electrical apparatus like transformers, generators, circuit breakers, insulators, and other sensitive equipment from overvoltages.

- Insulation Protection: Safeguards the insulation of power lines and equipment, which can be permanently damaged by excessive voltage.

- Continuity of Supply: By diverting surges, it helps prevent flashovers, outages, and equipment failures, thereby contributing to the reliability and continuity of electrical power supply.

- Personnel Safety: Reduces the risk of electrical shock to personnel by limiting dangerous voltage levels.

Types of Lightning Arresters:

- Rod Gap Arrester

- Horn Gap Arrester

- Multi-Gap Arrester

- Expulsion Type Arrester (Protector Tube)

- Valve Type Arrester (with nonlinear resistors like zinc oxide)

- Metal-Oxide Varistor (MOV) Arrester – common modern type

- Pellet Type Arrester

- Electrolytic Arrester

- Early Streamer Emission (ESE) Arresters

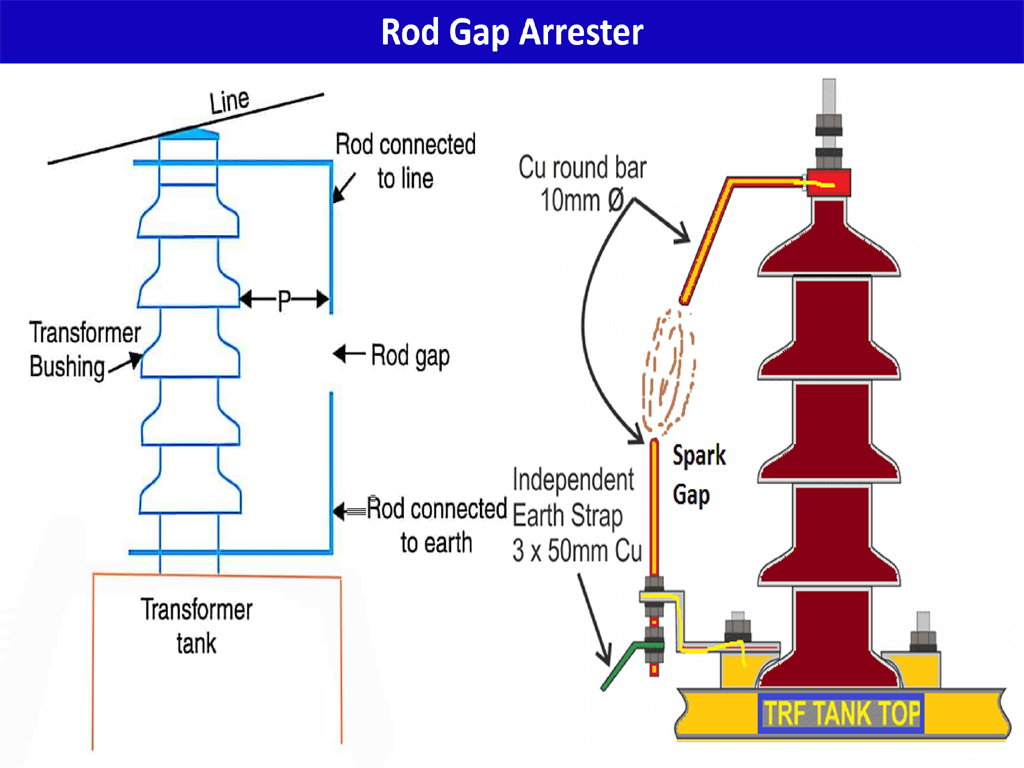

Rod Gap Arrester:

- Construction: The simplest type, consisting of two metal rods bent at right angles. One rod is connected to the line, and the other to the ground, with a small air gap between their tips.

Working Principle: When a surge voltage appears, the air in the gap ionizes, and an arc forms, providing a path for the surge to discharge to the ground.Limitations:

- No Arc Extinction: The main disadvantage is that once the arc is formed, it may continue to conduct the power frequency current even after the surge has passed, leading to a short circuit to ground. This requires a circuit breaker to operate to clear the fault.

- Weather Dependent: The spark-over voltage is affected by atmospheric conditions (humidity, dust).

Damage to Rods: The intense heat of the arc can melt or damage the rod tips.Fixed Spark-over Voltage: Not suitable for varying surge levels.

- Usage: Mostly obsolete in modern high-voltage systems due to its limitations, but still found in very old or low-cost installations.

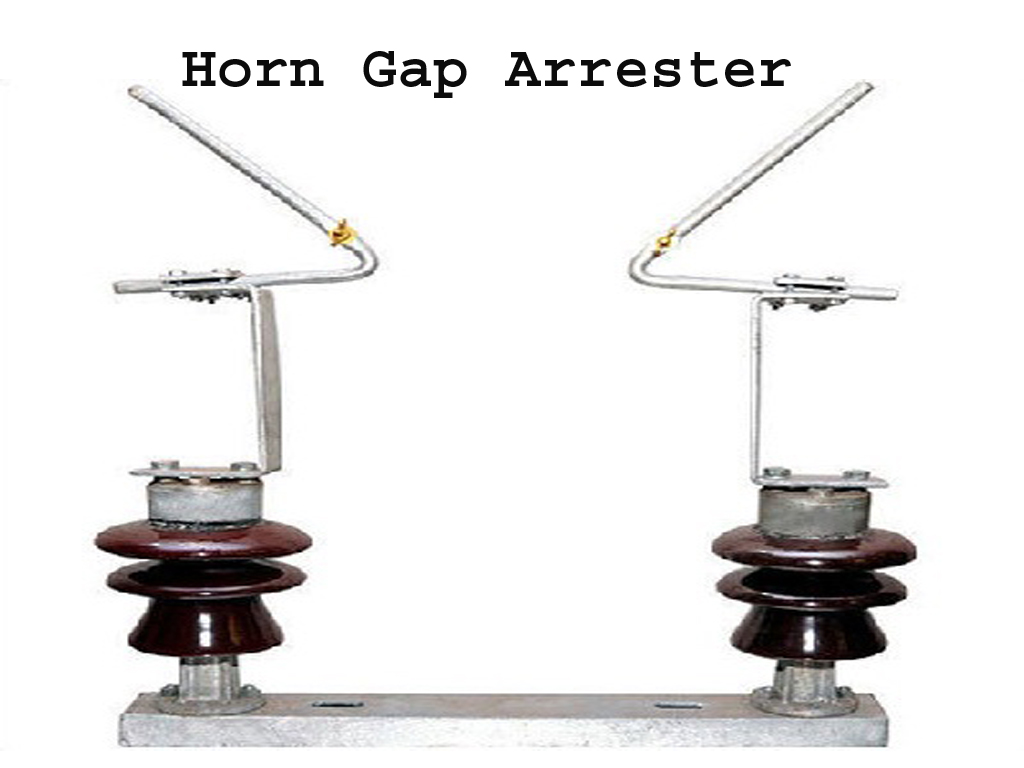

Horn Gap Arrester:

- Construction: Consists of two horn-shaped metal electrodes separated by a small air gap at the bottom. One horn is connected to the line, and the other to the ground. A series resistance and/or choke coil might be used.

Working Principle:

When a surge occurs, the air gap at the narrowest point sparks over. The heat of the arc causes it to rise due to convection and electromagnetic forces (similar to a magnetic blow-out coil effect). As the arc moves up the horns, it lengthens, eventually extinguishing itself when it becomes too long to sustain the normal power frequency voltage.

- Limitations:

- Still susceptible to follow current, although it has a mechanism to extinguish it.

- Arc extinction can be slow.

- Spark-over voltage varies with atmospheric conditions.

- Usage: More advanced than rod gaps but also largely replaced by modern types.

- Limitations:

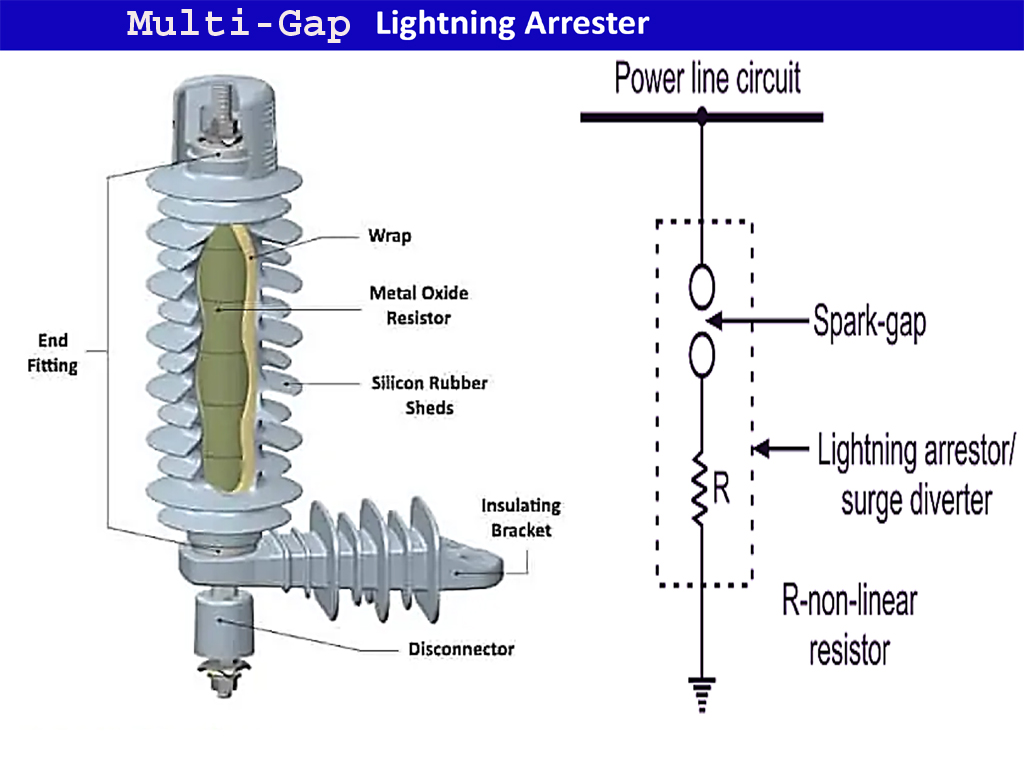

Multi-Gap Arrester:

- Construction: Comprises a series of small metallic cylinders (often an alloy of zinc) insulated from each other and separated by small air gaps. The first cylinder is connected to the line, and the last to the ground, often through a series resistance. Some gaps may have shunt resistances.

Working Principle:

The presence of multiple gaps helps to distribute the voltage stress and provide a more reliable discharge path. The series resistance helps limit the follow current.

- Limitations:

Complex construction, still involves air gaps, and less efficient than modern types.

- Usage: Also largely outdated.

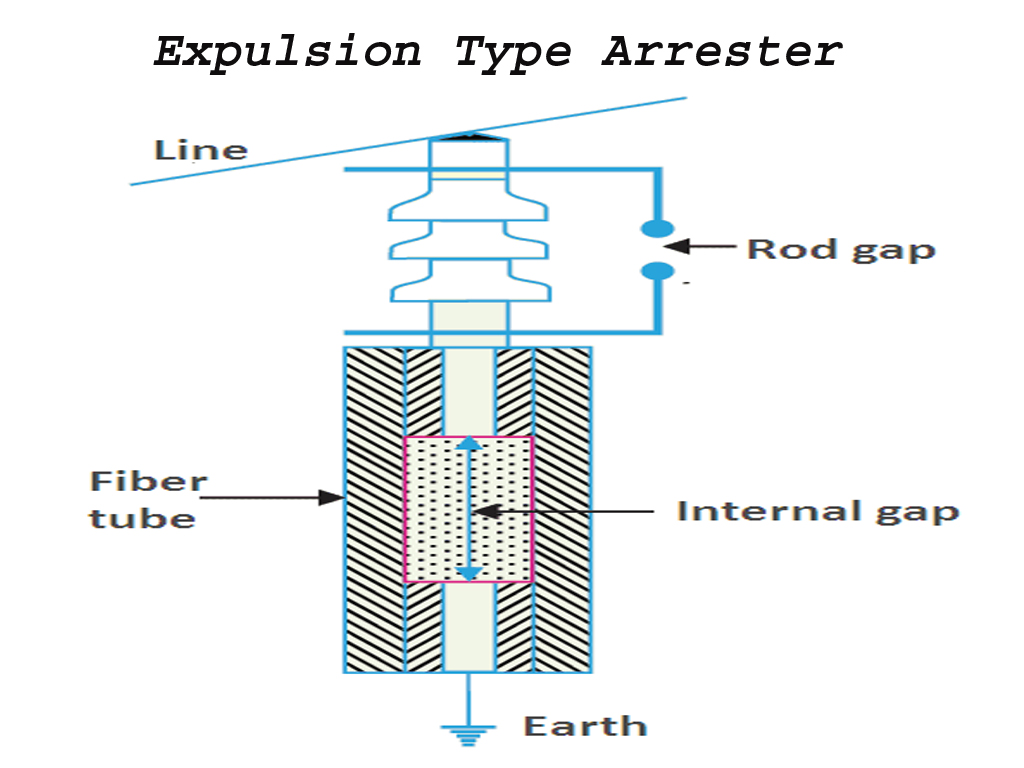

Expulsion Type Arrester (Protector Tube):

- Construction: An improvement over rod gaps, this arrester consists of a fiber tube with a series spark gap inside. One end of the tube is connected to the line, and the other end is open to the atmosphere.

- Working Principle: When a surge causes the gap to spark over, the arc heats and vaporizes the fiber tube material, producing a high-pressure gas. This gas blows out the arc, extinguishing the follow current.

- Limitations:

- Can only handle a limited number of operations.

- Generates loud noise and hot gases during operation, which can be dangerous in enclosed spaces.

- Not suitable for very high voltages or in areas where hot gas expulsion is problematic.

- Usage: Primarily used on distribution systems (up to 33 kV) where cost is a major factor.

Valve Type Arrester (Older Generation):

- Construction: Consists of a series of spark gaps in series with non-linear resistor discs (e.g., silicon carbide). The spark gaps break down during a surge, and the non-linear resistors limit the follow current.

- Working Principle: When an overvoltage occurs, the spark gaps ignite, creating a path to ground. The non-linear resistors then clamp the voltage to a safe level and limit the flow of power frequency current. Once the surge passes, the resistors’ impedance increases, extinguishing the arc across the gaps.

- Limitations:

- Still contains spark gaps, which have inherent limitations (response time, wear and tear).

- Not as efficient or fast as gapless designs.

- Usage: Mostly superseded by Metal Oxide Varistor (MOV) arresters.

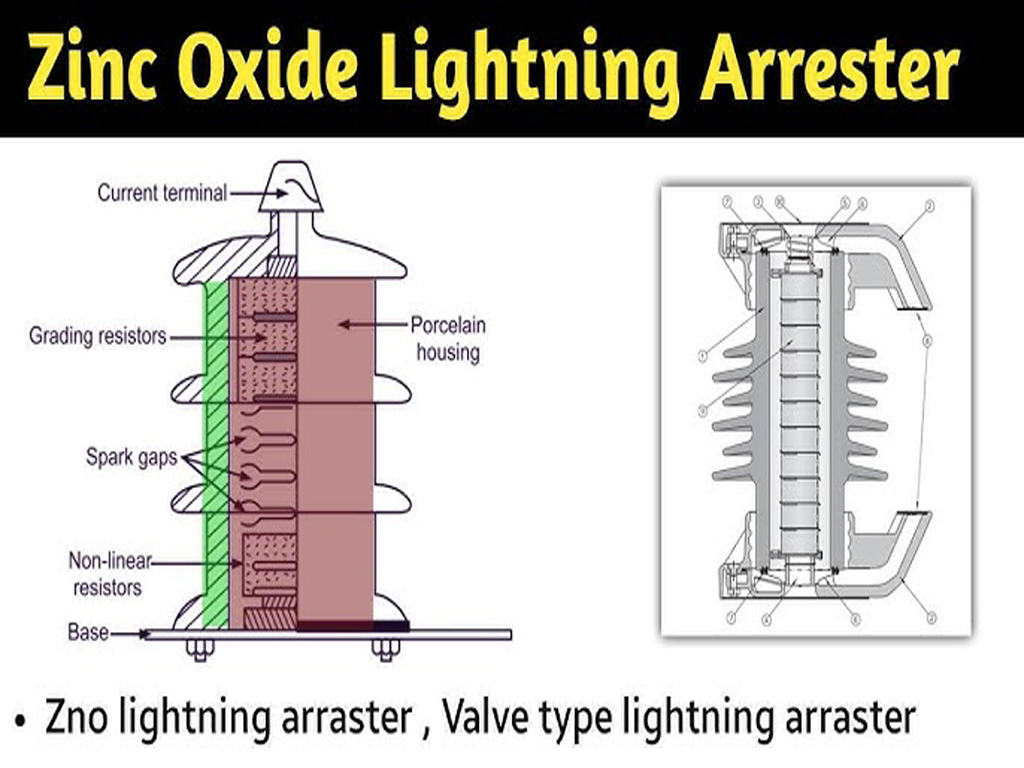

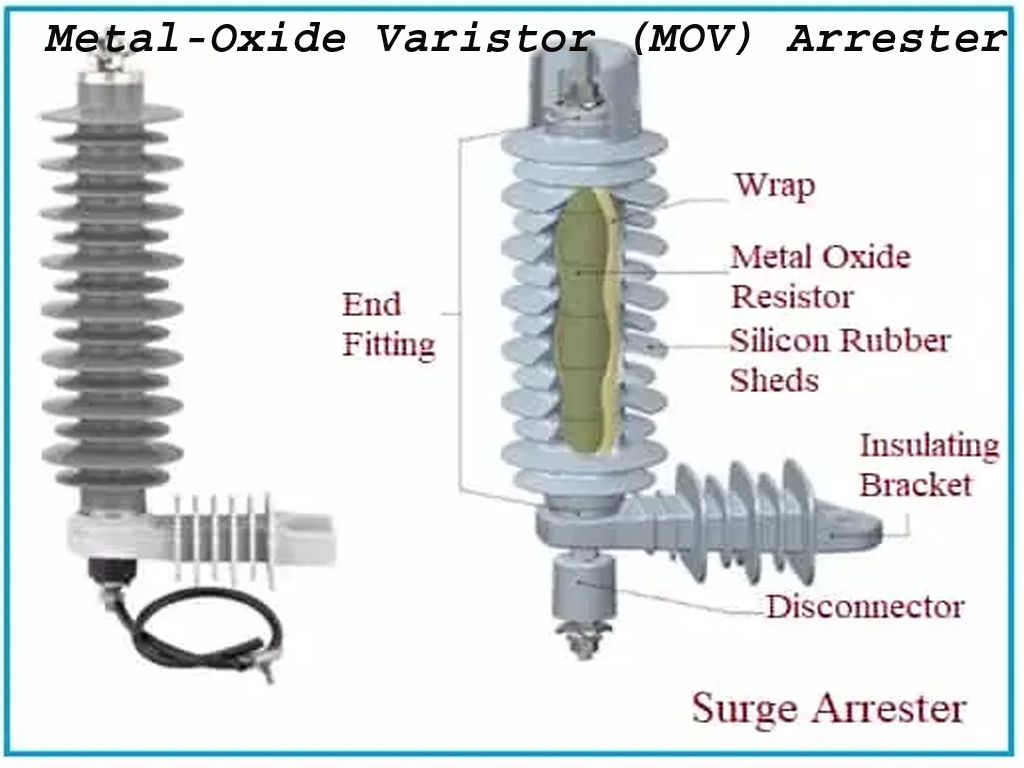

Metal Oxide Varistor (MOV) Arrester / Zinc Oxide (ZnO) Arrester:

- Construction: This is the most widely used type of lightning arrester in modern power systems, from distribution to EHV (Extra High Voltage) levels. It consists of a stack of highly non-linear ceramic resistor discs made primarily of zinc oxide (ZnO), often mixed with other metal oxides. These discs are enclosed in a hermetically sealed porcelain or polymer housing.

Working Principle:

- Normal Conditions: At normal system voltage, the ZnO material has extremely high resistance, allowing only a very small leakage current to flow (in microamperes). Essentially, it acts as an insulator.

- During Overvoltage: When a transient overvoltage (from lightning or switching) appears, the voltage across the MOV discs rapidly increases. The unique non-linear characteristic of ZnO causes its resistance to exponentially decrease at a specific voltage threshold (the “knee point” of its V-I characteristic).

- Diverting and Clamping: This sudden drop in resistance creates a very low-impedance path, allowing the large surge current to flow to the ground, thereby “clamping” the voltage across the protected equipment to a safe, predetermined level (the “residual voltage”).

- Self-Restoring: Once the surge current dissipates and the system voltage returns to normal, the ZnO material’s resistance instantly reverts to its high-impedance state, effectively “sealing” the path to ground without any follow current.

Advantages:

- Gapless Design: No air gaps to spark over, leading to faster response times and no follow current.

- Excellent Non-Linearity: Highly effective in limiting overvoltages to very low residual values.

- High Energy Absorption: Can handle significant surge energy.

Reliability: Very reliable and requires minimal maintenance.

- Compact Size: Often more compact for a given voltage rating.

- Usage: Dominant type used across all voltage levels in substations, transmission lines, distribution systems, and even in surge protective devices for homes and electronics.

These arresters do not rely on air gaps for operation, making them faster, more reliable, and capable of handling more energy.

Other less Common or Specialized Types:

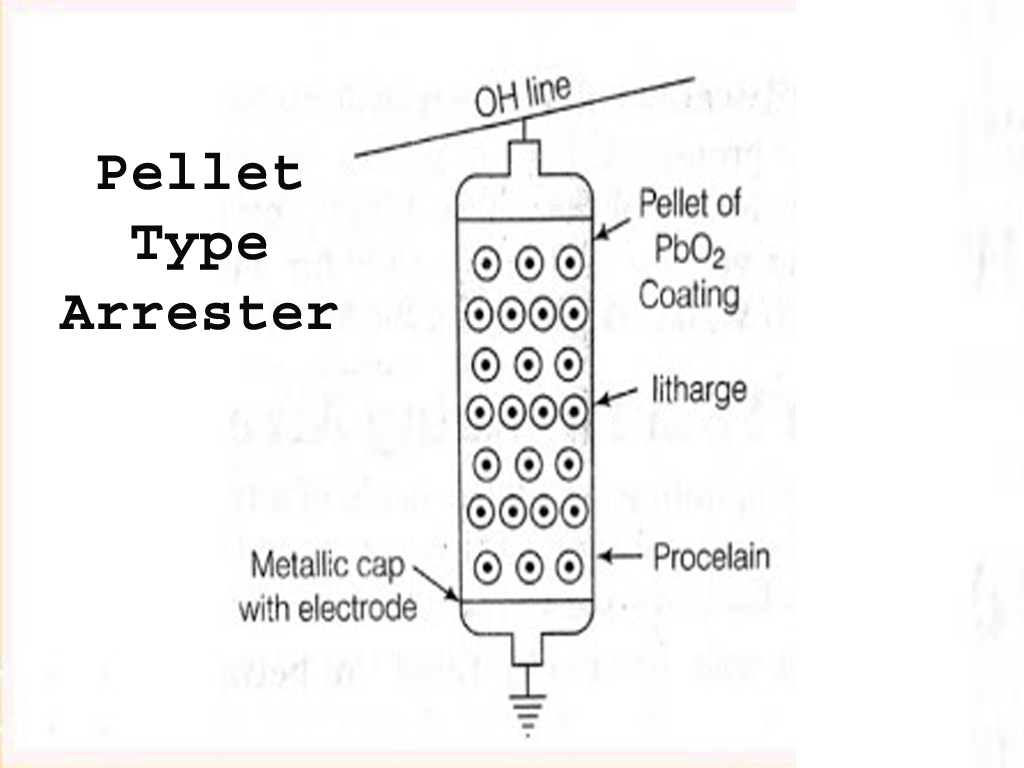

Pellet Type Arrester:

An older type using lead peroxide pellets. Less common now.

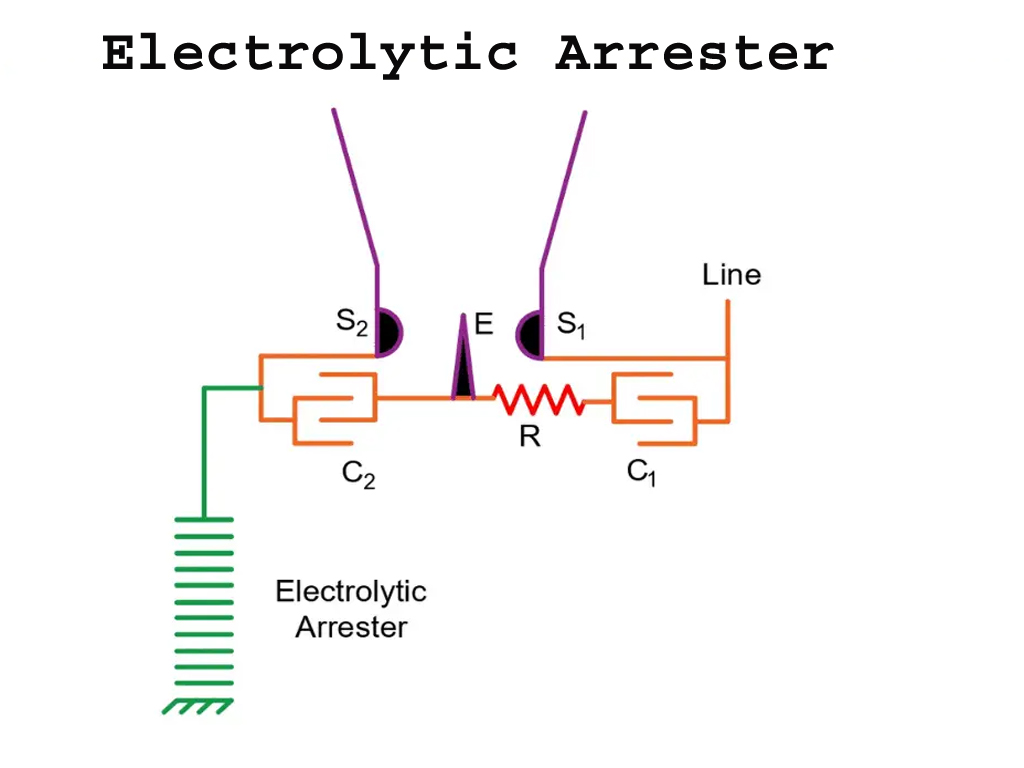

8. Electrolytic Arrester:

Operated on the principle of electrolytic cells, forming high resistance films at low voltage. Largely obsolete.

9. Early Streamer Emission (ESE) Arresters: These are a type of lightning rod, not strictly an arrester in the same way as MOV, but rather a system designed to “attract” lightning to a specific point and guide it safely to the ground before it strikes other parts of a structure. They generate an upward streamer earlier than conventional lightning rods.

In modern power systems, the Metal Oxide Varistor (MOV) arrester is the workhorse for surge protection due to its superior performance, reliability, and gapless design. The older gapped arresters are largely being phased out due to their limitations.

Where are Lightning Arresters Installed?

Lightning arresters are strategically installed at points where equipment is most vulnerable to overvoltage:

Substations: Near transformers, circuit breakers, and bus bars.Power Plants: To protect generators and associated equipment.Transmission Lines: On transmission towers, especially at line terminations or where line characteristics change.

- Distribution Lines: On poles near distribution transformers or service entrances to buildings.

- Buildings: To protect internal electrical systems and appliances (smaller versions known as surge protectors).

In essence, a lightning arrester acts as a guardian, standing ready to absorb and divert the destructive energy of voltage surges, ensuring the integrity and safety of the entire electrical system.

Difference between Lightning Arrester and Surge Arrester

A Lightning Arrester is a specialized surge arrester focused mainly on protecting from lightning.

A Surge Arrester is a broader category that protects against all transient overvoltages, including lightning.

The terms Lightning Arrester and Surge Arrester are often used interchangeably, but they have distinct differences in scope and application.

Here’s a clear comparison:

| Feature | Lightning Arrester | Surge Arrester |

| Purpose | Specifically protects against lightning strikes | Protects against all types of voltage surges, including lightning, switching surges, and transient overvoltages |

| Application | Mostly used in outdoor high-voltage power transmission systems | Used in both indoor and outdoor electrical systems (homes, industries, substations) |

| Voltage Levels | Typically for high-voltage systems (above 11 kV) | Available for low, medium, and high-voltage systems |

| Construction | Often simpler (e.g., rod gaps, spark gaps, etc.) | More advanced (e.g., metal oxide varistors (MOVs) for precise control) |

| Response Time | Very fast, designed to handle direct lightning strikes | Fast, designed to handle a wide range of overvoltage events |

| Typical Location | Mounted on power poles, transformers, transmission lines | Found in residential surge protectors, industrial panels, and substations |

Advantages of lightning arrestor:

- Protects Equipment:

Prevents costly damage to electrical devices, transformers, and power lines due to lightning strikes. - Reduces Downtime:

Keeps systems operational during storms, reducing power outages and service interruptions. - Improves Safety:

Minimizes the risk of electrical fires or injuries caused by high-voltage surges. - Low Maintenance:

Most modern lightning arresters require little to no maintenance once installed. - Fast Operation:

Responds instantly to overvoltage, protecting equipment in microseconds. - Extends Equipment Life:

By preventing voltage spikes, it helps extend the lifespan of expensive electrical infrastructure.

Disadvantages of lightning arrestor:

- Limited to High Voltage Protection:

Not designed to protect against low-voltage surges (like those from switching operations or internal faults). - Does Not Absorb Energy:

It only diverts the surge to the ground—it doesn’t absorb or eliminate it. - Installation Cost:

Can be costly to install, especially for high-voltage systems or in remote locations. - Requires Proper Grounding:

Without effective grounding, the arrester may fail to protect or may even become a hazard itself. - Not Always Effective Against Indirect Strikes:

May not fully protect sensitive electronic devices from indirect or induced surges unless combined with other protection systems.

FAQs (Frequently Asked Questions)

🔹 1. What is a lightning arrester?

A lightning arrester is a device that protects electrical systems by safely diverting high-voltage surges (caused by lightning) to the ground, preventing damage to equipment.

🔹 2. How does a lightning arrester work?

When a high voltage surge (like from a lightning strike) travels through a power line, the arrester provides a low-resistance path to ground, allowing the surge to bypass sensitive equipment.

🔹 3. Where is a lightning arrester installed?

It is typically installed:

- At the entry point of overhead lines into a building or substation

- On transformers, transmission lines, and distribution poles

- Near communication towers or electronic installations

🔹 4. Is a lightning arrester the same as a surge protector?

Not exactly. A lightning arrester is primarily for lightning-induced surges and used in high-voltage systems, while a surge protector handles a broader range of overvoltages, including those from switching operations, and is used in homes and offices.

🔹 5. Does a lightning arrester need grounding?

Yes, effective earthing (grounding) is essential. Without a proper ground connection, the arrester cannot safely divert the surge, and equipment remains unprotected.

🔹 6. What are the types of lightning arresters?

Common types include:

- Rod gap arrester

- Horn gap arrester

- Valve type arrester

- Metal Oxide Varistor (MOV) arrester – most widely used today

🔹 7. Can a lightning arrester protect electronics?

Only indirectly. For direct protection of electronics (like computers), use a surge protector or secondary surge arrester along with the main lightning arrester.

🔹 8. How long does a lightning arrester last?

Most modern arresters last 10–20 years, depending on environmental conditions and lightning activity. Regular inspection ensures performance.

🔹 9. What happens if a lightning arrester fails?

If it fails, the surge may reach equipment, causing burnout, fire, or system failure. Some arresters have failure indicators or fuses to show damage.

🔹 10. Is maintenance required?

Minimal. However, in high-risk or critical systems, regular inspection and testing are recommended to ensure functionality.