What is an Electric Motor?

An electric motor is an electromechanical device that converts electrical energy into mechanical energy. This mechanical energy is typically in the form of rotational motion (torque), It is widely used in machines, fans, pumps or any other mechanical system vehicles and household appliances.

Electric Motor Works on the Principle of…

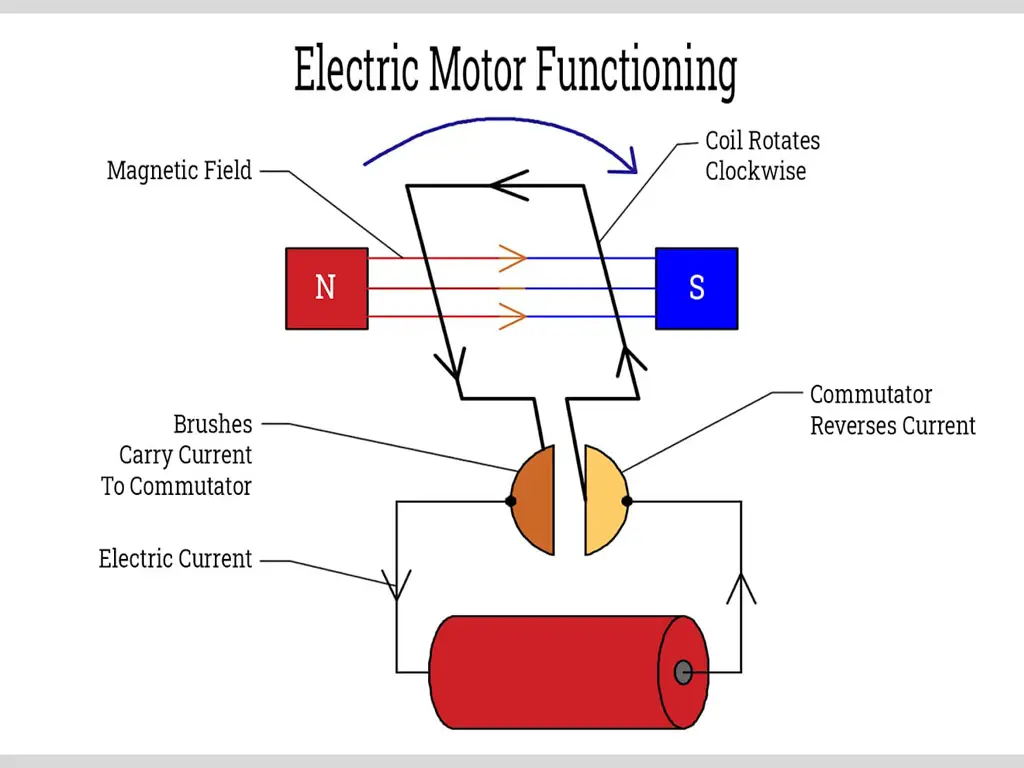

Electric motors primarily work on the principle of electromagnetic induction (or more broadly, electromagnetism). Specifically, they utilize the Lorentz force, which states that a current-carrying conductor placed in a magnetic field experiences a force.

In simpler terms:

- When an electric current flows through a wire, it creates its own magnetic field around the wire.

- If this current-carrying wire is placed within an external magnetic field (from a permanent magnet or another electromagnet), these two magnetic fields interact.

- This interaction results in a force being exerted on the wire.

- In an electric motor, this force is cleverly arranged to produce a continuous rotational motion.

Fleming’s Left-Hand Rule is often used to determine the direction of the force, current, and magnetic field in motors. If you point your forefinger in the direction of the magnetic field (North to South), your middle finger in the direction of the current, then your thumb will point in the direction of the force (motion) on the conductor.

Transformation Process: Electrical Energy to Mechanical Energy

The transformation from electrical energy to mechanical energy in an electric motor can be broken down into these steps:

- Electrical Input: Electrical energy (in the form of current and voltage) is supplied to the motor’s windings.

- Magnetic Field Generation:

- In the stator (stationary part), either permanent magnets create a constant magnetic field, or electromagnets (coils of wire) are energized by the input current to produce a magnetic field.

- In the rotor (rotating part), current also flows through coils of wire (armature windings), creating a second, interacting magnetic field.

- Interaction of Magnetic Fields (Lorentz Force): The magnetic field generated by the stator interacts with the magnetic field generated by the rotor’s windings. Due to this interaction, a force is exerted on the current-carrying conductors in the rotor.

- Torque Production: Because the rotor windings are arranged in coils, the forces on opposite sides of the coil act in opposite directions, creating a torque (a rotational force) that causes the rotor to spin around its central axis.

- Continuous Rotation (Commutation in DC Motors): For continuous rotation, the direction of the current in the rotor coils needs to be reversed at specific points in its rotation.

- In DC motors, this is achieved by a mechanical component called a commutator and brushes. The commutator is a split ring that reverses the direction of the current in the coil every half rotation, ensuring the torque always acts in the same direction.

- In AC motors, the alternating nature of the current naturally provides the necessary reversal of magnetic fields to maintain continuous rotation.

- Mechanical Output: The continuous rotation of the rotor is then transmitted through a shaft, providing mechanical energy to drive external loads. This mechanical energy is primarily kinetic energy (rotational motion).

Notes: an electric motor does not transform potential energy into mechanical energy directly. Instead, it transforms electrical potential energy (associated with the voltage difference driving the current) into magnetic field energy (as current flows and creates magnetic fields) and then into mechanical kinetic energy (the rotation of the shaft). The electrical energy supplied is a form of potential energy that gets converted.

Internal Components of an Electric Motor

While there are many types of electric motors, the core components generally include:

Stator:

- This is the stationary outer part of the motor.

- It contains either permanent magnets or field windings (coils of wire) that create the stationary magnetic field.

- The stator core is often made of laminated steel to reduce energy losses from eddy currents.

Rotor (Armature):

- This is the rotating inner part of the motor.

- It typically consists of armature windings (coils of wire) wrapped around a laminated ferromagnetic core.

- When current flows through these windings, they create a magnetic field that interacts with the stator’s field.

- The rotor is mounted on a shaft.

Shaft:

- This is a central rod attached to the rotor.

- It is the component that delivers the mechanical rotational energy to the external load.

Bearings:

- These support the shaft and allow the rotor to spin smoothly with minimal friction. They are crucial for efficiency and longevity.

Commutator (for DC Motors):

- A segmented copper ring attached to the rotor.

- It works with the brushes to periodically reverse the direction of current in the armature windings, ensuring continuous, unidirectional torque.

Brushes (for DC Motors):

- Stationary carbon or graphite contacts that press against the commutator segments.

- They provide electrical connection between the stationary power supply and the rotating armature windings.

Air Gap:

- The small space between the stator and the rotor.

- It’s kept as small as possible to ensure efficient magnetic field interaction.

Casing/Housing:

- The outer protective shell of the motor, which encloses and supports all the internal components.

- Often includes cooling fins or a fan to dissipate heat generated during operation

In summary, an electric motor is a masterful application of electromagnetism, converting the ordered flow of electrons (electrical energy) into the ordered rotational movement of a mechanical shaft (mechanical energy) through the clever interplay of magnetic fields