What is Direct Online (DOL) Starter?

Answer: A Direct Online (DOL) starter for a single-phase motor is a straightforward method used to start and stop the motor by directly connecting it to the single-phase power supply at full voltage. It’s essentially a switch with built-in protection mechanisms.

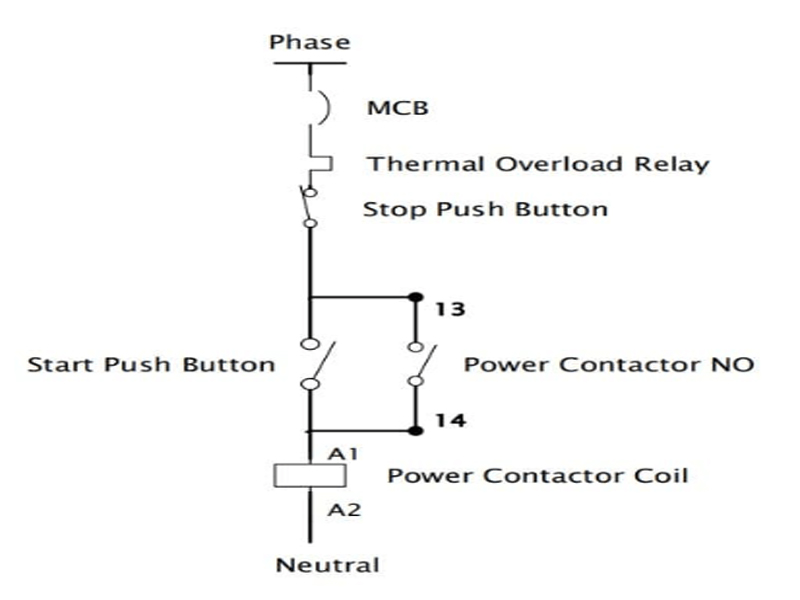

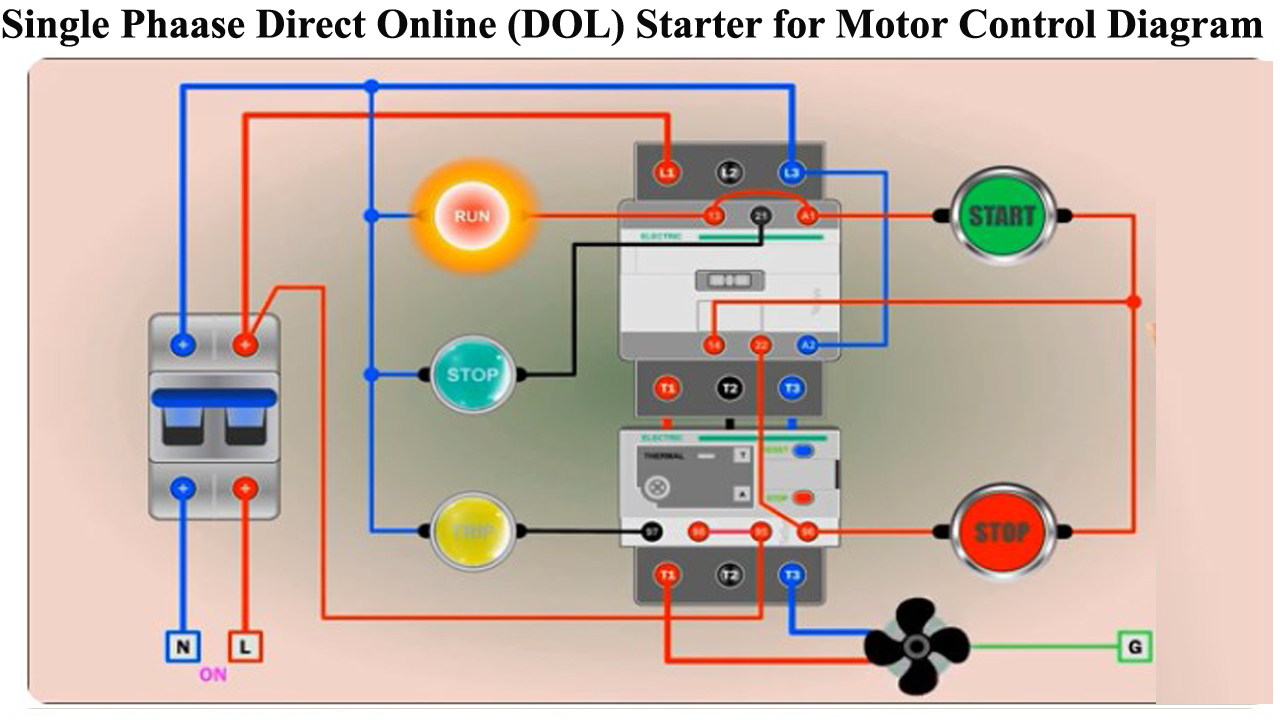

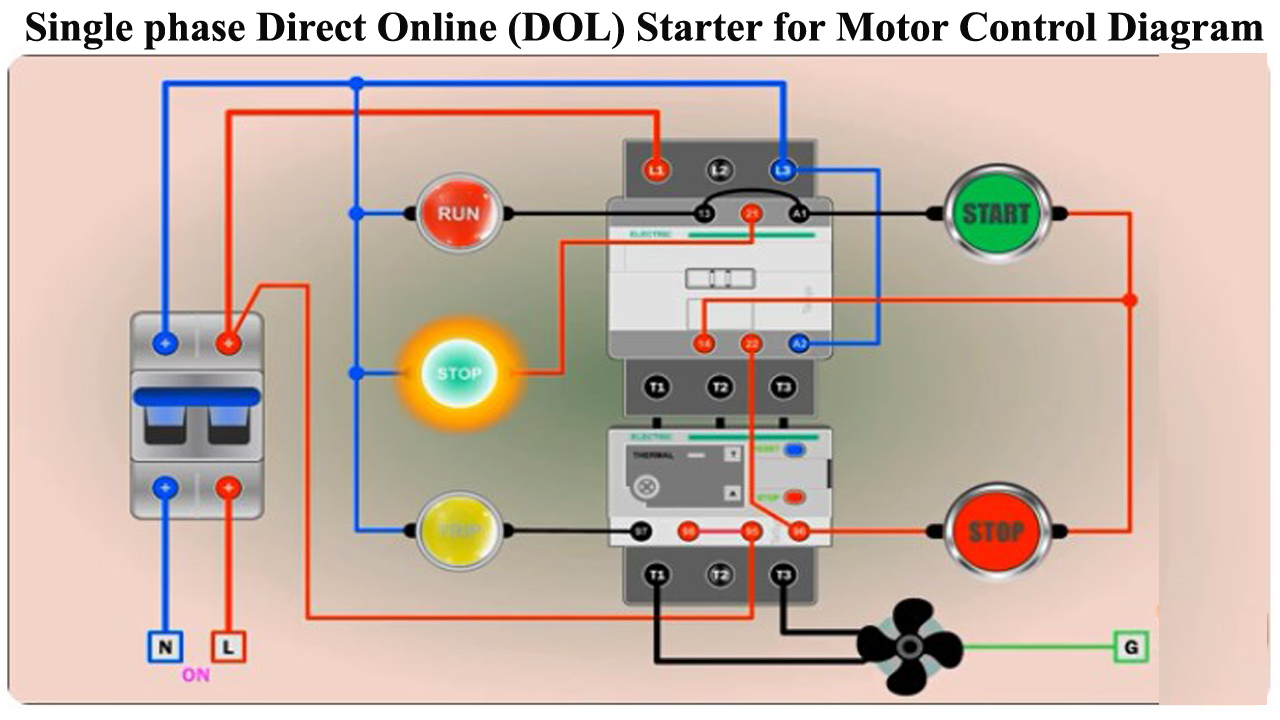

Working Principle:

When the start button is pressed, it energizes a double-pole contactor, which then closes its main contacts. This directly connects both the live and neutral wires of the single-phase power supply to the motor’s main winding and its starting circuit. The motor’s internal starting mechanism (like a capacitor and auxiliary winding) then initiates the rotation, drawing a high starting current. Once running, an auxiliary contact on the contactor creates a latching circuit to keep the contactor energized even after the start button is released. Pressing the stop button de-energizes the contactor, disconnecting the power and stopping the motor. An overload relay is important for protecting the motor from overcurrent conditions.

Components:

- Circuit Breaker or Fuses: Provide short-circuit protection.

- Double-Pole Magnetic Contactor: Switches both live and neutral lines.

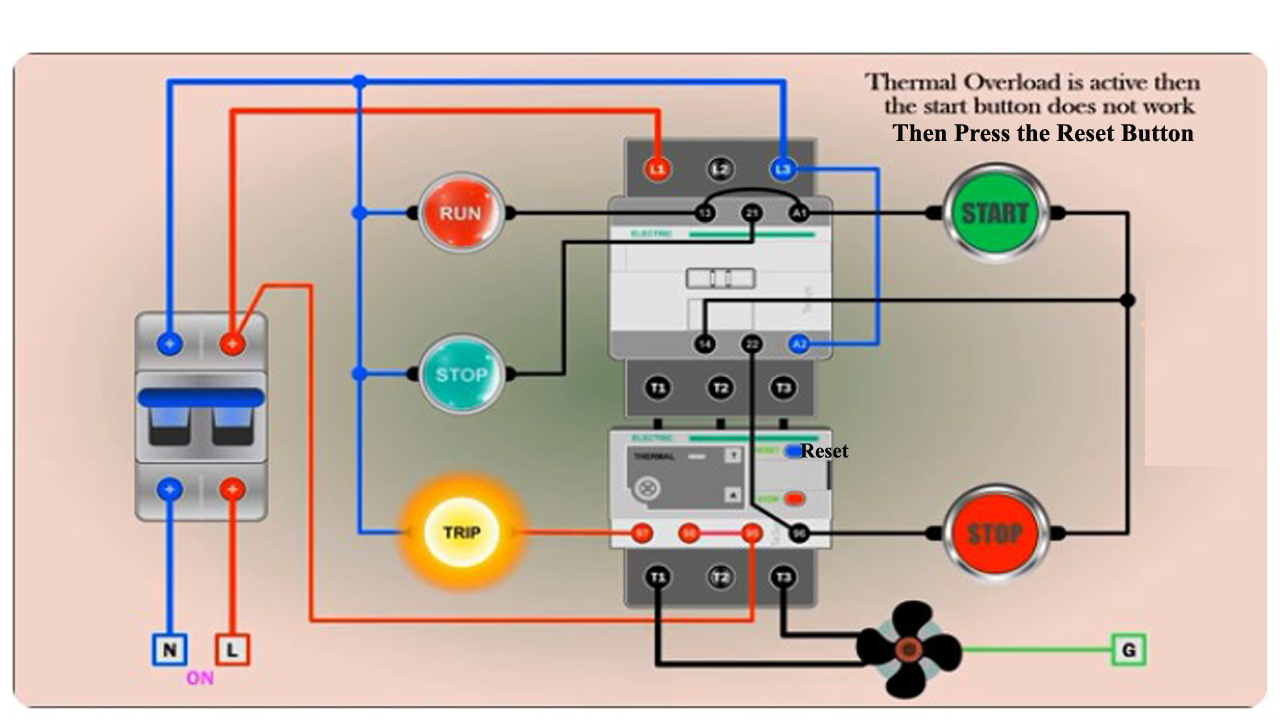

- Overload Relay (OLR): Protects against overcurrent and overloads. It needs to be correctly rated for the single-phase motor’s current. Sometimes, a three-pole OLR is used by passing both live and neutral through different poles for proper sensing.

- Start Button (Green Button)– Initiates the motor start-up process. It energizes the contactor coil, allowing current to flow to the motor.

- Stop Button (Red Button)– It stops the motor. De-energizes the contactor coil, cutting off the current to the motor.

- Wiring and Terminals: To connect the components.

- Auxiliary Contacts – Provide additional control and feedback functions. It maintains the contactor coil’s energization even after the start button is released, guaranteeing continuous motor operation.

- Enclosure – Protects all internal components from dust, moisture, and physical damage. It also ensures the safety and durability of the DOL starter.

When Start Condition,

When Stopped Condition:

When Trip Condition:

Advantages:

- Simple and Economical: The most basic and cost-effective starting method for smaller single-phase motors.

- Easy to Install and Maintain: Simple wiring and operation.

- Full Starting Torque: Provides the maximum torque the motor can produce at startup.

Disadvantages:

- High Starting Current: Draws a large inrush current, potentially causing voltage drops.

- High Starting Torque (can be a disadvantage): May cause mechanical stress if not needed.

- Limited to Smaller Motors: Generally used for lower power ratings where the starting current impact is acceptable.

Applications:

DOL starters for single-phase motors are commonly used for:

- Small water pumps

- Fans and blowers

- Small compressors

- Some power tools

- Household appliances in industrial settings

In essence, a DOL starter for a single-phase motor is a simple and direct way to start and protect it, primarily suited for smaller motors where the high starting current doesn’t pose significant problems.

Related Post:

Three Phase Direct Online (DOL) Starter Wiring Diagram

Star Delta Starters

Reverse Forward Starter Control Wiring Diagram

FAQ:

1. Why is an overload relay used in a DOL starter?

Answer: To protect the motor from overheating due to overcurrent. It trips the circuit when the motor draws current beyond the preset limit for too long.

2. Where is a single-phase DOL starter commonly used?

Answer: In small pumps, compressors, fans, and other light-duty applications where motors up to 3 HP are used.

3. What is the purpose of the holding contact in a DOL starter?

Answer: The holding contact (also known as an auxiliary contact or latching contact) is a normally open contact that is mechanically linked to the contactor’s main contacts. When the “Start” button is pressed and the contactor energizes, this holding contact closes. It then provides an alternative current path to the contactor coil, allowing the operator to release the “Start” button while the contactor remains energized and the motor continues to run. This creates a self-latching circuit.

4.What happens when the “Stop” button of a DOL starter is pressed?

Answer: The “Stop” button is a normally closed contact in the control circuit of the contactor coil. When the “Stop” button is pressed, it momentarily opens this circuit, interrupting the current flow to the contactor coil. This de-energizes the electromagnet in the contactor, causing the main contacts (which were supplying power to the motor) and the holding contact to open. Opening the main contacts disconnects the motor from the power supply, stopping it.

5. What could be some common faults or issues that might occur with a single-phase DOL starter?

Answer: Common faults or issues can include:

- Contactor Failure: Contacts may become worn, pitted, or welded shut. The coil might burn out.

- Overload Relay Tripping: Frequent tripping indicates an overload condition, a fault in the motor, or an incorrectly set relay.

- Loose Wiring: Can lead to intermittent operation or failure to start.

- Button Malfunction: Start or stop buttons may become stuck or fail to make/break contact.

- Blown Fuses (if present): Often a symptom of a more significant fault like a short circuit.