What is PLC?

PLC stands for Programmable Logic Controller. It is a type of industrial digital computer designed to control manufacturing processes, such as assembly lines, robotic devices, or any activity that requires high reliability, ease of programming, and process fault diagnosis.

Here’s a breakdown of what that means:

- Programmable: It can be programmed to perform a wide variety of tasks. Unlike older hard-wired relay systems, a PLC’s control logic is implemented through software. This program can be easily modified to change the behavior of the controlled system without rewiring.

- Logic-based: It uses logic operations (like AND, OR, NOT) to make decisions.

- Controller: It monitors inputs (sensors, switches) and controls outputs (motors, lights, valves) accordingly.

- Industrial Environment: PLCs are built to withstand harsh conditions like extreme temperatures, humidity, dust, and vibrations, which are common in industrial settings.

Key characteristics of a PLC:

- Input / Output (I/O) Modules: PLCs have interfaces to connect to various input devices (like sensors, switches, and buttons) and output devices (like motors, valves, and lights).

- Central Processing Unit (CPU): This is the “brain” of the PLC, where the control program is executed.

- Memory: Stores the control program and data.

- Power Supply: Provides the necessary power for the PLC to operate.

- Programming Interface: Allows users to create, download, and monitor the control program. Common programming languages include Ladder Logic, Function Block Diagram, Structured Text, Instruction List, and Sequential Function Charts.

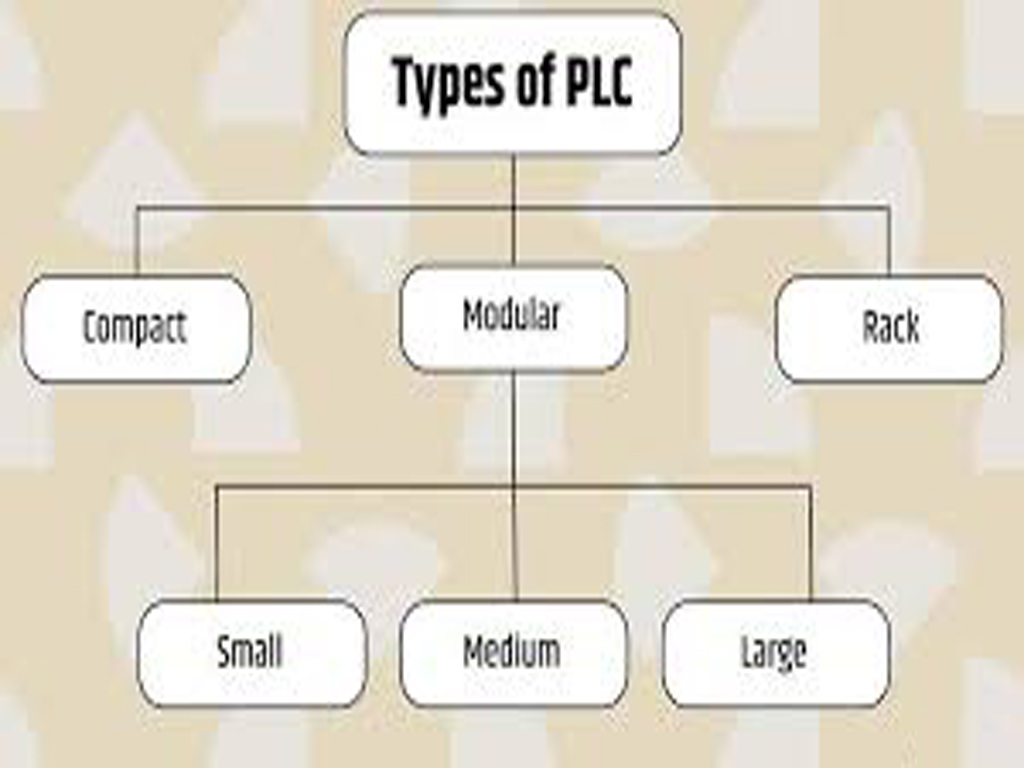

Types of PLCs

PLCs come in several types, classified based on their size, functionality, and application. Here’s a breakdown of the main types of PLCs:

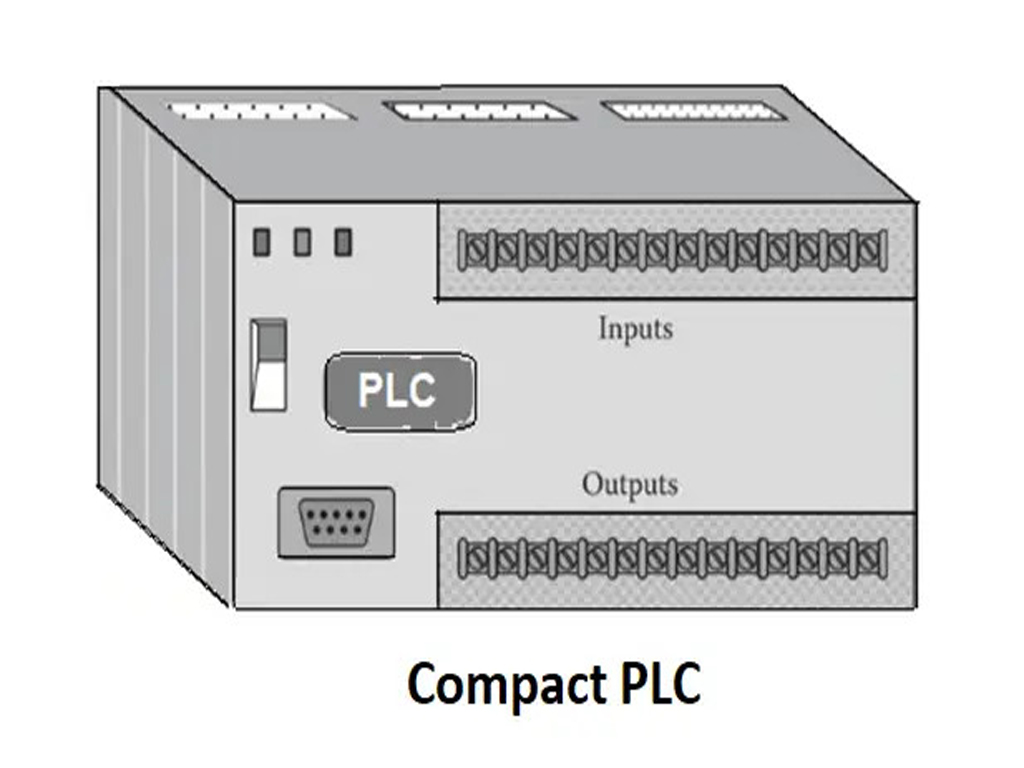

1. Compact (Fixed) PLC

- Description: All components (CPU, power supply, I/O modules) are built into a single unit.

- Advantages: Small, cost-effective, simple to install.

- Use Case: Small machines or standalone systems with limited I/O requirements.

2. Modular PLC

- Description: Components like CPU, input/output modules, and power supply are separate and can be added or replaced.

- Advantages: Highly flexible, scalable, and easier to maintain.

- Use Case: Medium to large industrial systems with complex control needs.

Types of Modular PLCs by Size

i. Small Modular PLCs

Description: Compact with limited I/O modules; suitable for small-scale automation.

Use Case: Simple machinery, packaging units, HVAC systems.

Features:

Up to a few hundred I/O points.

Basic communication options (RS-232/RS-485, Ethernet).

Limited program memory.

ii. Medium Modular PLCs

Description: Mid-range capacity, supports a larger number of modules and features.

Use Case: Process automation, production lines, and moderate machine control.

Features:

Several hundred to a few thousand I/O points.

Advanced communication (Ethernet/IP, Profibus, Modbus).

PID control, data logging, HMI integration.

iii. Large Modular PLCs

Description: High-end systems with extensive capabilities.

Use Case: Large plants, distributed systems, power plants, oil & gas.

Features:

Thousands of I/O points.

Redundancy support (CPU, power supply).

Distributed control via remote I/O racks.

Integrated SCADA support, safety and motion control.

3. Rack-Mounted PLC

- Description: A more advanced form of modular PLC where modules are mounted in a rack or chassis.

- Advantages: Supports a large number of modules; suitable for distributed systems.

- Use Case: Large industrial plants, process automation, or systems requiring remote I/O.

4. Soft PLC

- Description: PLC functionality is provided by software running on a standard PC.

- Advantages: Lower hardware cost, easy integration with other PC-based applications.

- Use Case: Simulation, training, or PC-based control environments.

5. Safety PLC

- Description: Designed to meet safety regulations and standards (e.g., SIL, ISO).

- Advantages: Provides safe shutdown in hazardous environments.

- Use Case: Automotive, chemical plants, or machinery with safety-critical operations.

How a PLC works (simplified scan cycle):

- Input Scan: The PLC reads the status of all connected input devices.

- Program Scan: The CPU executes the control program based on the input status.

- Output Scan: The PLC updates the status of all connected output devices based on the results of the program execution.

- This cycle repeats continuously and rapidly, allowing for real-time control of the industrial process.

Physical Structure of PLC

The physical structure of a PLC typically consists of several key components housed in a robust enclosure designed for industrial environments. These components work together to receive input signals, execute the control program, and generate output signals.

Power Supply Unit (PSU):

- This module provides the necessary electrical power for the PLC to operate.

- It converts the incoming AC or DC power (depending on the model) to the low DC voltages (commonly 24V DC, but others exist) required by the CPU, memory, and I/O modules.

- It often includes features like over current protection and voltage regulation to ensure stable and reliable operation.

- In some smaller PLCs, the power supply might be integrated into the CPU module. Larger, modular PLCs usually have a separate, replaceable power supply module.

Central Processing Unit (CPU) Module:

- This is the “brain” of the PLC. It contains the microprocessor that executes the control program stored in memory.

- It communicates with the I/O modules to read input data and send output commands.

- The CPU module often includes indicators for power status, run/program mode, and errors.

- It has connectors for programming cables and sometimes for communication networks.

Memory Module:

- This section stores the PLC’s operating system, the user-written control program, and data such as input/output status, timer/counter values, and other variables.

- PLCs typically use a combination of different types of memory:

- ROM (Read-Only Memory): Stores the PLC’s firmware and operating system, which are permanent and cannot be changed by the user.

- RAM (Random Access Memory): Used for storing the user program and temporary data during operation. This memory is usually volatile and requires a battery backup to retain data during power loss.

- Non-Volatile Memory (like EEPROM or Flash): Used to store the user program and retentive data that needs to be preserved even when power is off, often replacing or supplementing battery-backed RAM.

- In some PLCs, the memory might be integrated into the CPU module, while others have separate memory cards or modules.

Input/Output (I/O) Modules:

- These modules act as the interface between the PLC and the external world (sensors, actuators, etc.).

- They come in various types to handle different signal types:

- Digital Input (DI) Modules: Receive discrete (on/off) signals from devices like switches, push buttons, and proximity sensors. They convert these signals into a digital format that the CPU can understand.

- Digital Output (DO) Modules: Send discrete (on/off) signals to control devices like relays, solenoids, and indicator lights. They convert the digital signals from the CPU into the appropriate voltage and current to drive these outputs.

- Analog Input (AI) Modules: Receive continuous signals (e.g., voltage or current) from sensors measuring parameters like temperature, pressure, or flow. They convert these analog signals into digital values for the CPU to process.

- Analog Output (AO) Modules: Generate continuous signals (e.g., voltage or current) to control analog devices like variable speed drives or proportional valves. They convert digital values from the CPU into analog signals.

- Specialty Modules: These can include high-speed counter modules, communication modules (for protocols like Ethernet, Modbus, etc.), motion control modules, and more, depending on the application requirements.

- I/O modules are typically modular and can be added or removed to match the number and type of input and output points needed for a specific application. They often have terminal blocks or connectors for field wiring.

Mounting Rack or Chassis:

- For modular PLCs, the CPU, power supply, and I/O modules are mounted on a backplane or rack.

- The rack provides mechanical support and electrical connections (power and communication bus) between the different modules.

- Racks come in various sizes to accommodate different numbers of modules.

Communication Interface:

- PLCs often have one or more communication ports for programming, monitoring, and communication with other devices or systems (e.g., HMIs, other PLCs, supervisory control systems).

- Common communication interfaces include Ethernet, USB, RS-232, RS-485, and various industrial network protocols.

Indicators and Diagnostic LEDs:

- Most PLC modules have LEDs to indicate their status (e.g., power on, running, error, input/output status). These are crucial for troubleshooting and system monitoring.

Applications of PLCs are vast and include:

- Manufacturing: Controlling assembly lines, robotic systems, packaging machines, and material handling.

- Automotive: Automation in car manufacturing processes.

- Food and Beverage: Controlling processing, packaging, and bottling.

- Power Plants: Monitoring and controlling various equipment like boilers and turbines.

- Water Treatment: Controlling filtration, chemical dosing, and pumping systems.

- Transportation: Traffic light control, automated trains, and elevators.

- Building Automation: Controlling HVAC systems, lighting, and security.

- Automated production lines

- Conveyor systems.

Advantages of using PLCs:

- Flexibility: Programs can be easily changed and updated.

- Reliability: Designed for harsh industrial environments.

- Speed: Real-time control and fast response times.

- Ease of Troubleshooting: Built-in diagnostics help identify and resolve issues quickly.

- Compact Size: Take up less space compared to traditional relay systems.

- Networking Capabilities: Can communicate with other control systems and devices.

Disadvantages of using PLCs:

- Initial Cost: Can be expensive depending on the complexity.

- Requires Training: Personnel need to be trained to program, maintain, and troubleshoot PLCs.

- Fixed Circuit Operation (to some extent): The fundamental hardware architecture is fixed, although the software provides flexibility.

In essence, the PLC is a workhorse of modern industrial automation, providing a robust, reliable, and programmable solution for controlling complex machinery and processes.