A hydro-power plant generates electricity by harnessing the energy of flowing water, converting kinetic energy into electrical power through turbines and generators

In hydroelectric power plants, turbines are essential components that convert the kinetic energy of flowing water into mechanical energy, which is then used to generate electricity. The choice of turbine depends on the characteristics of the water flow, such as the head (height of the water drop) and the flow rate (volume of water passing through the plant).

There are several types of turbines used in hydroelectric power plants, each designed for specific operational conditions:

Pelton Turbine:

- Type: Impulse turbine

- Head Requirement: High head (large vertical distance, typically over 300 meters)

- Water Flow: Low to medium flow rate

- Usage: Best suited for locations with steep, fast-moving water (high head, low flow).

- Working Principle: Pelton turbines are impulse turbines that convert the energy of high-pressure water jets into mechanical energy. The water is directed onto spoon-shaped buckets on the turbine wheel, causing the wheel to rotate.

- Design: Pelton turbines have one or more buckets mounted around the circumference of the turbine runner. The water jet strikes the buckets and imparts momentum, turning the turbine.

- Advantages:

- Highly efficient in high-head, low-flow situations.

- Simple and durable.

- Example: Often used in mountainous regions where water drops from great heights.

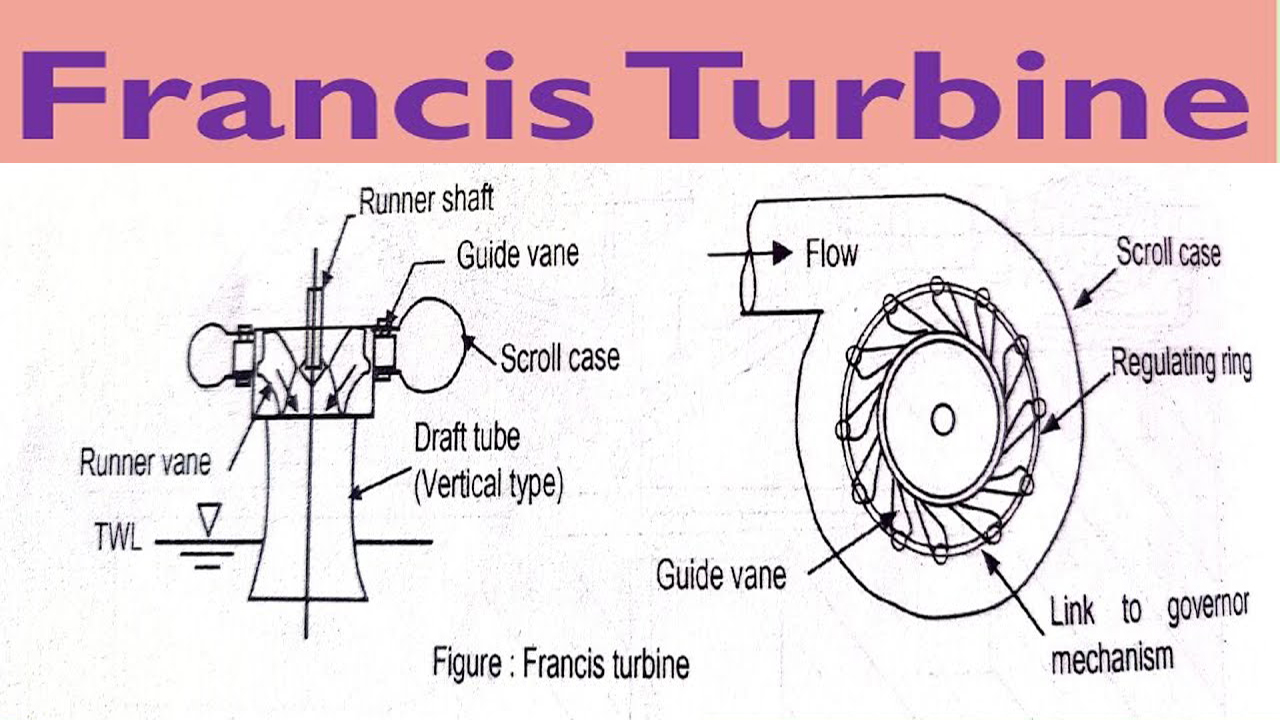

Francis Turbine

- Type: Reaction turbine

- Head Requirement: Medium head (20 to 700 meters)

- Water Flow: High flow rate

- Usage: Suitable for medium to high head and moderate flow applications.

- Working Principle: Francis turbines work on the principle of both impulse and reaction. Water enters radially from the outside and flows inward, where it then changes direction and moves through the turbine blades, causing them to rotate.

- Design: The turbine’s runner has curved blades, and the water enters the turbine radially and leaves axially (from the center). The reaction created by the water flow generates power.

- Advantages:

- Highly efficient in a wide range of flow and head conditions.

- Suitable for plants with moderate water flow.

- Example: Commonly used in large-scale hydroelectric plants, including those with a moderate head.

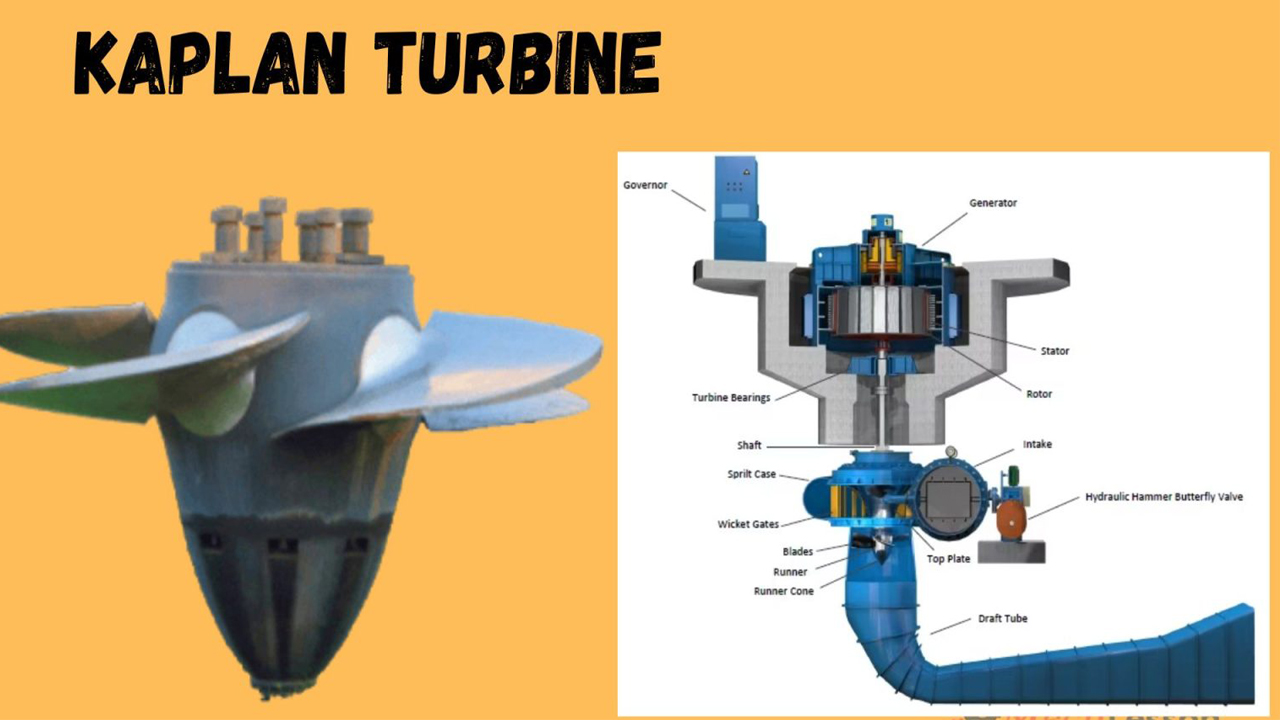

Kaplan Turbine

- Type: Reaction turbine (axial-flow)

- Head Requirement: Low head (2 to 30 meters)

- Water Flow: Very high flow rate

- Usage: Ideal for locations with low water heads but high flow, such as river flows.

- Working Principle: The Kaplan turbine is a variation of the Francis turbine, but with adjustable blades that can change the angle of the water flow. This allows it to operate efficiently in low-head conditions with high flow.

- Design: The runner has adjustable blades, and water flows through the blades in an axial direction (from one end of the turbine to the other).

- Advantages:

- Efficient at low heads with high flow rates.

- The adjustable blades allow for optimization based on varying flow conditions.

- Example: Used in run-of-river plants or plants with low-head, high-flow conditions like those found in coastal regions or large rivers.

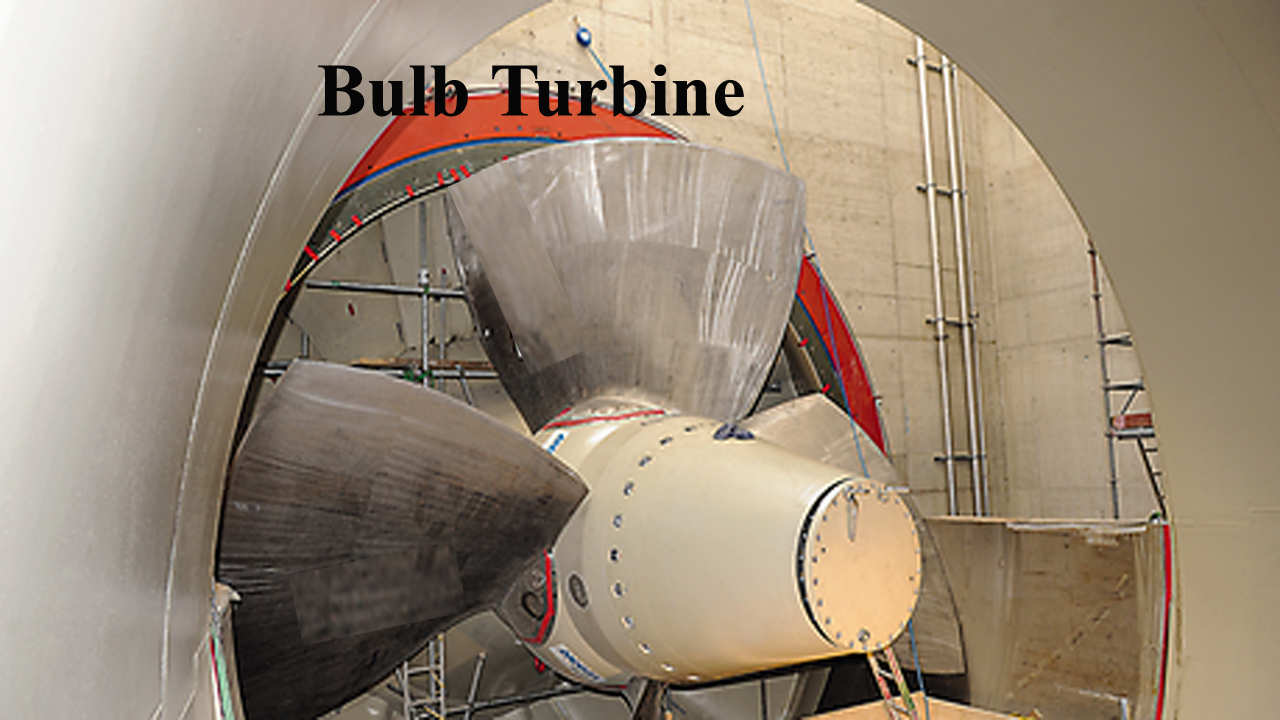

Bulb Turbine

- Type: Reaction turbine (a variation of the Kaplan turbine)

- Head Requirement: Very low head (1 to 15 meters)

- Water Flow: Very high flow rate

- Usage: Used in very low-head, high-flow situations where other turbines would be inefficient.

- Working Principle: Similar to the Kaplan turbine, but with the turbine and generator enclosed in a “bulb” shaped casing. The water flows through the turbine’s runner and then passes through the bulb, where it drives a generator.

- Design: The turbine runner and generator are submerged in a large bulb-shaped casing, and the water flows axially through the blades.

- Advantages:

- Suitable for very low head, high-flow locations.

- Compact design.

- Example: Often used in areas with low head, such as tidal and canal-based hydro plants.

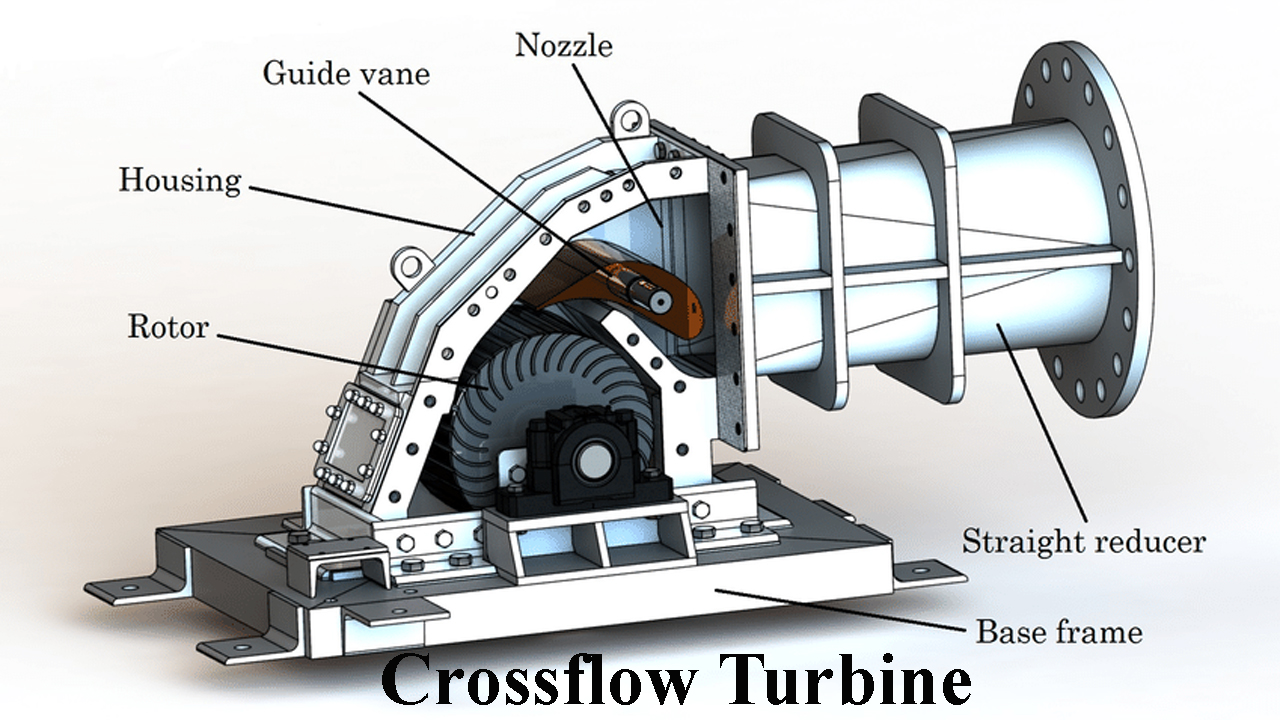

- Crossflow Turbine

- Type: Impulse turbine

- Head Requirement: Medium to low head

- Water Flow: Moderate to high flow

- Usage: Suitable for small-scale hydroelectric plants with varying water flow and medium head.

- Working Principle: Water flows through the turbine in two directions: first radially through the blades, and then axially through the runner. The water imparts energy to the turbine through the blades, which then rotates.

- Design: The water enters through the side of the turbine and flows over the blades in a crosswise manner. The unique design allows it to be used in small hydro projects or places with varying water levels.

- Advantages:

- Simpler design than Francis or Pelton turbines.

- Works well in varying flow conditions.

- Example: Often used in small or micro-hydro power plants.

Each turbine type is chosen based on specific site conditions (head and flow) to maximize efficiency and power output.

Related Post:

What Is a Hydro Power Plant and How Does It Work?

How to Choose the Right Energy Storage System for Your Needs

The Benefits of Co-Generation: A Comprehensive Guide to Combined Heat and Power Systems