What is insulator?

An insulator is a material that prevents the flow of electric current. In electrical systems, insulators are used to support and separate electrical conductors without allowing the current to flow through them, thus preventing short circuits and ensuring safety.

In overhead power lines, insulators are essential components that support the conductors (wires) and prevent them from coming into contact with the ground or other structures. They also prevent the leakage of electrical current to nearby objects.

Types of Insulators in Overhead Lines:

Pin Insulator:

Pin Insulator - It is mounted on a pin (hence the name) on the cross-arm of the pole and is commonly used in low-voltage distribution lines.

- Made of porcelain or glass.

- It is cost-effective and simple in design

- Used for lower voltage distribution lines, typically up to 33 kV.

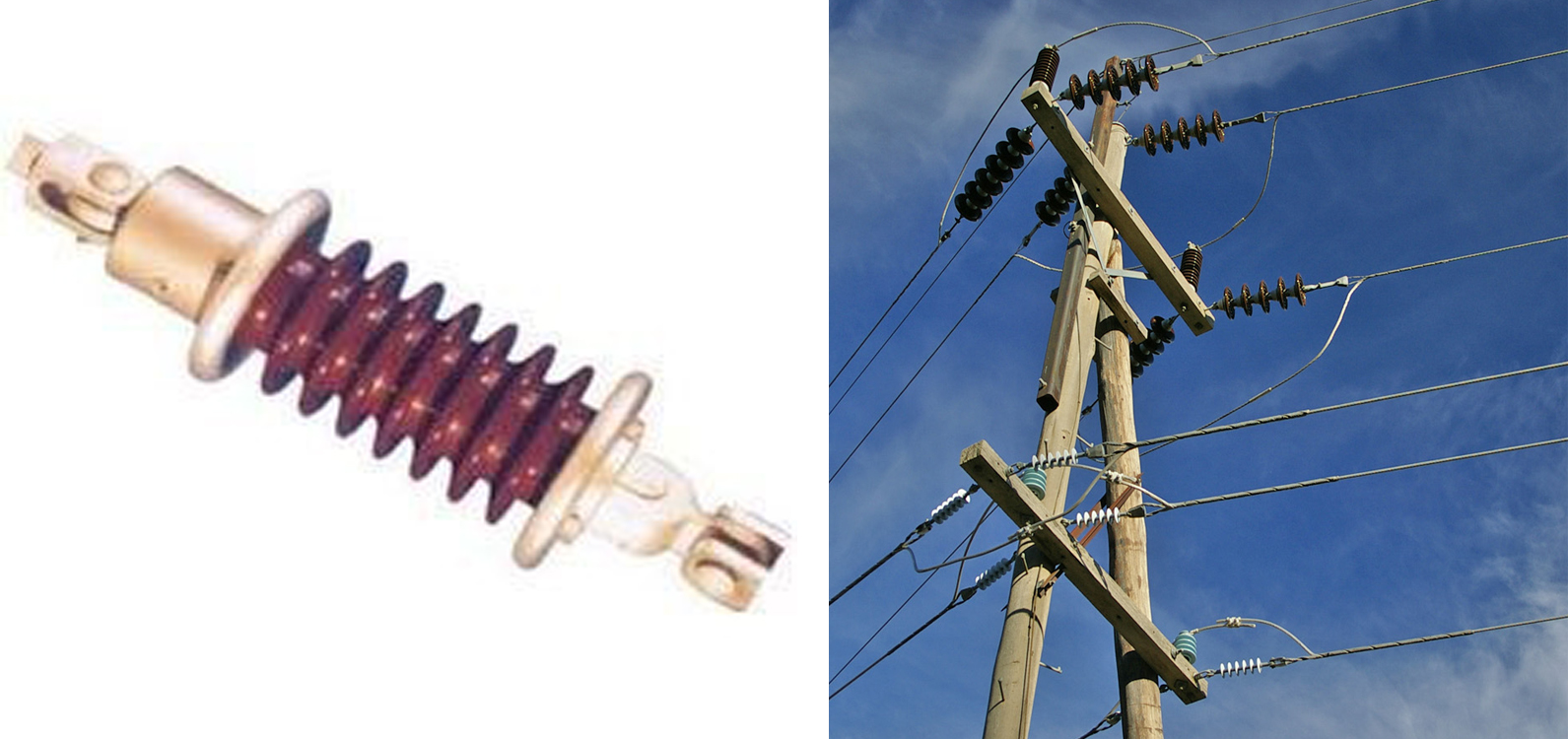

Suspension Insulator:

Suspension Insulator - Used for higher voltage transmission lines (more than 33 kV).

- Consists of a series of porcelain discs connected in series by metal fittings.

- These insulators are connected in a string (suspension insulator string), allowing for easy replacement of individual discs.

- The number of discs can be increased to handle higher voltages.

- Offer flexibility and better mechanical strength.

Strain Insulator:

Strain Insulator - Used to bear the mechanical tension in overhead lines.

- They are used in places where conductors experience high tension due to the line’s length or terrain.

- These are usually used in combination with suspension insulators.

- Can be made of porcelain or glass, similar to suspension insulators, but are often used in a horizontal position.

- Stay Insulators:

- Used in stay wires, which are used to support poles and prevent them from tilting.

- Must have high mechanical strength and good insulating properties.

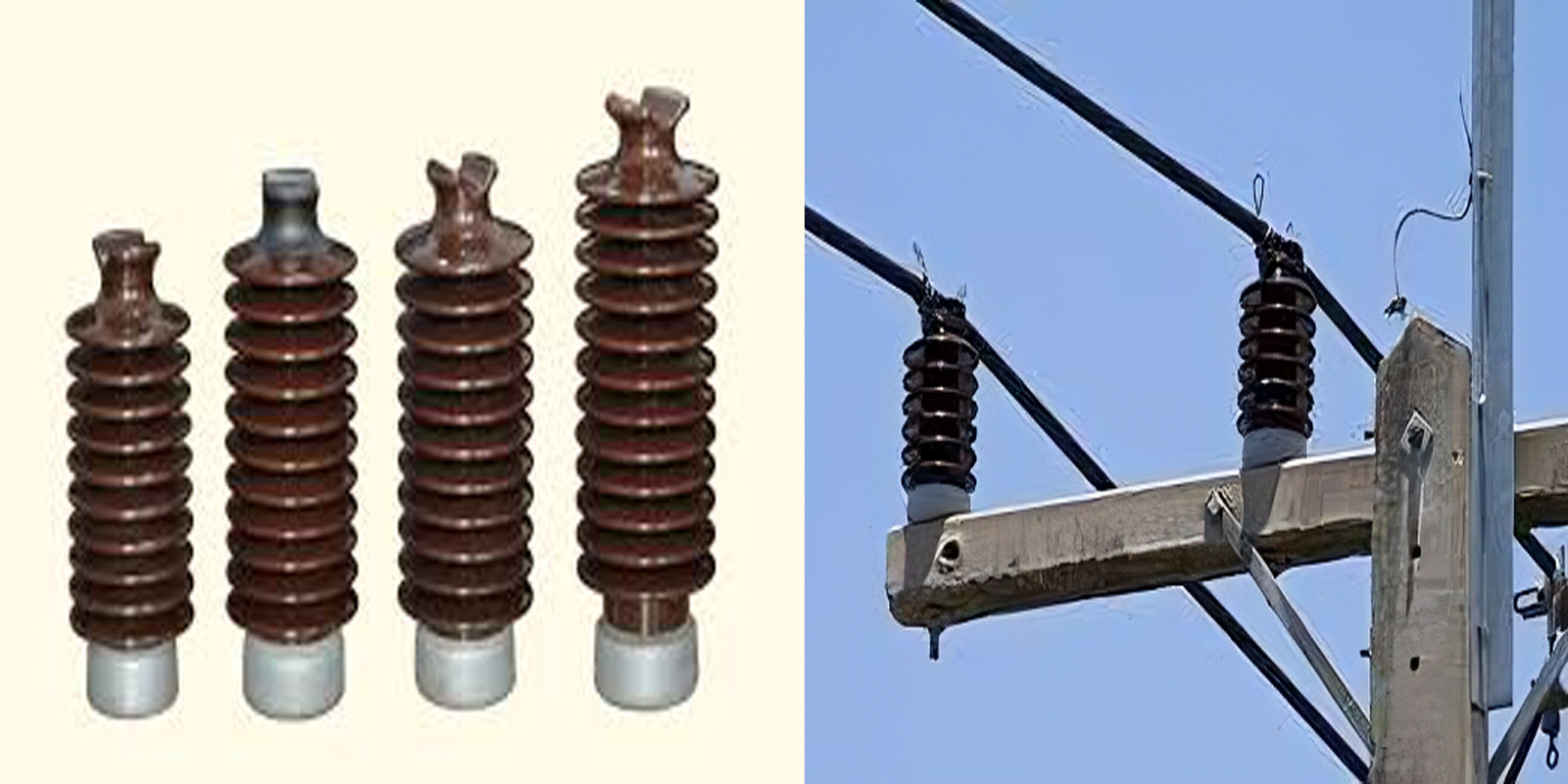

Post Insulators:

Post Insulators

- Used in substations and for supporting busbars and equipment.

- Designed for higher voltages and provide rigid support.

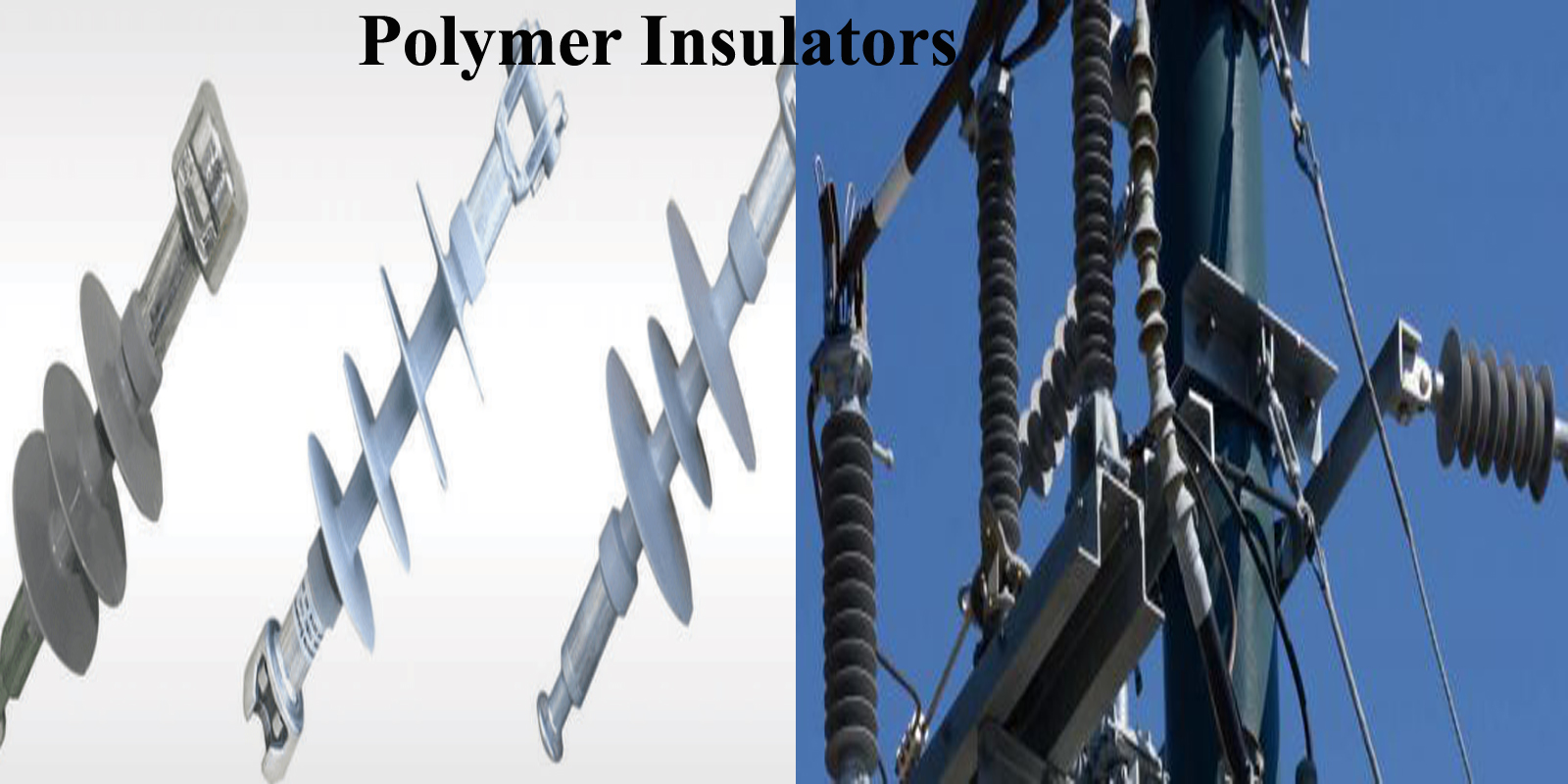

Polymer Insulators:

- Made of fiberglass reinforced polymer materials.

- Lighter than porcelain or glass insulators.

- Offer good resistance to weathering and contamination.

- Increasingly used in overhead lines due to their advantages.

7. Shackle Insulator:

- A type of pin insulator that is used for medium-voltage lines.

- Made of porcelain and is shaped to fit the wire securely.

- It is used in smaller distribution systems, especially for lower-voltage applications.

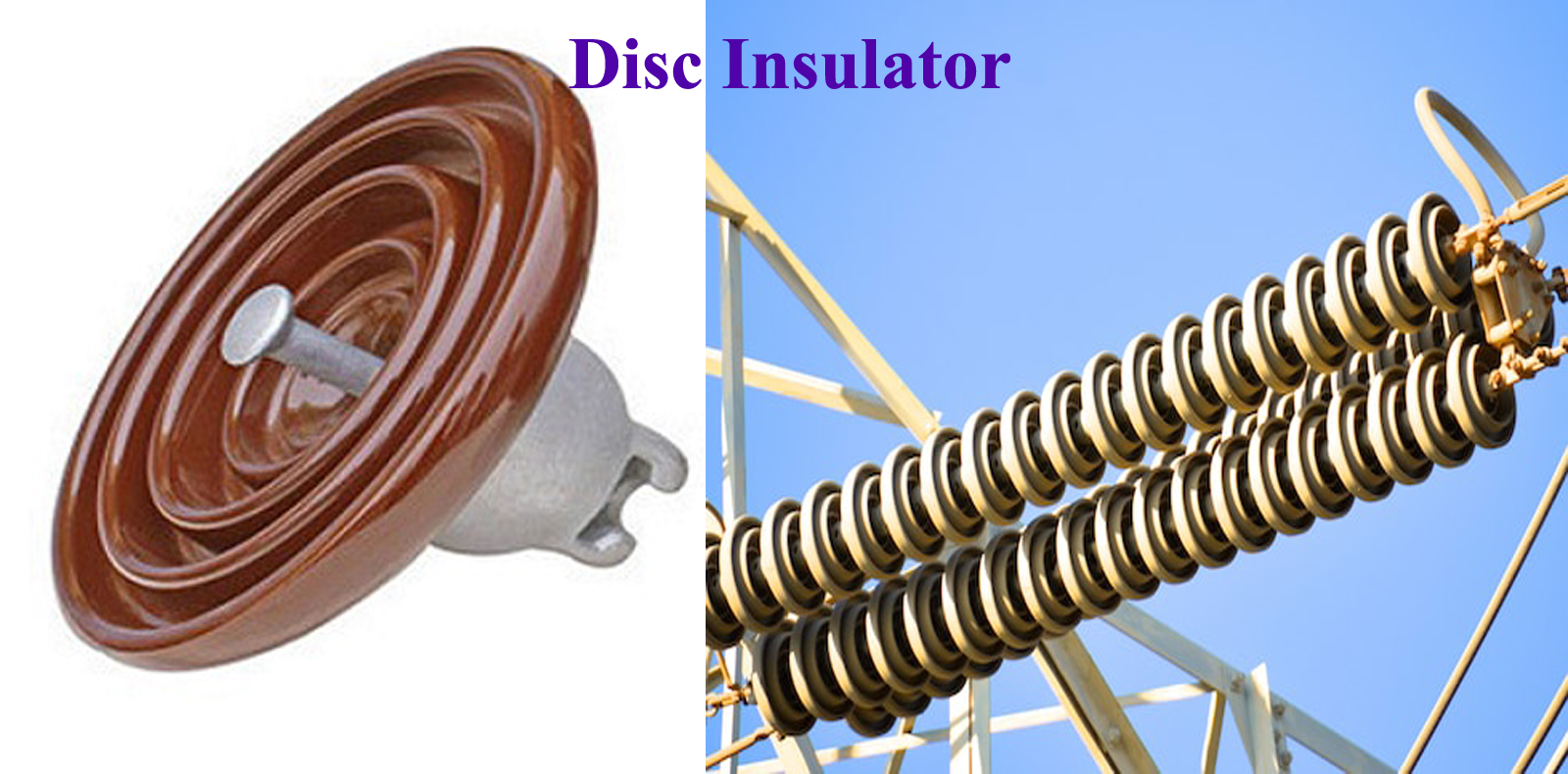

8. Disc Insulator:

- A type of suspension insulator made up of porcelain or glass discs.

- Used in high-voltage transmission lines and can be stacked together to achieve the required electrical strength.

9. Ball and Socket Insulator:

- These insulators are used in situations where flexibility is required (such as in lines subjected to wind or vibration).

- They are designed to allow movement while still providing electrical insulation.

Each type of insulator is designed to handle specific voltage levels and mechanical stresses. The choice of insulator depends on factors such as the voltage of the line, environmental conditions, and mechanical load.

Factors to Consider When Choosing Insulators:

- Voltage: The insulator must be able to withstand the operating voltage of the line.

- Mechanical strength: The insulator must be strong enough to support the conductors and withstand mechanical stresses.

- Environmental conditions: The insulator must be resistant to weathering, contamination, and other environmental factors.

- Cost: The cost of the insulator must be considered in relation to its performance and reliability.

Applications of Insulators in Overhead Lines:

- Supporting Conductors: Insulators are used to support and separate conductors in overhead power lines, preventing them from touching the ground or other structures.

- Preventing Electrical Leakage: They prevent electrical current from leaking to nearby objects or the earth, ensuring the safety of both the system and individuals in the vicinity.

- High-Voltage Transmission: Insulators are used in high-voltage transmission lines to isolate the conductors from the supporting towers or poles, enabling the efficient transmission of electricity over long distances.

- Ensuring System Reliability: They provide stability to the transmission system by preventing short circuits or ground faults, which can lead to power outages or equipment damage.

- Reducing Losses: Insulators help in minimizing losses due to the leakage of electricity, especially in systems with high voltages.

- Distribution Networks: Insulators are essential in distributing electricity from substations to homes and businesses. Pin insulators and polymer insulators are often used in these applications.

- Special Applications: Strain insulators are used where lines change direction or terminate, while stay insulators support the poles themselves. Post insulators are common in substations.

Advantages of Insulators in Overhead Lines:

- Safety: Insulators ensure that the electrical current does not flow into the support structures, reducing the risk of electric shock and providing a safer environment for maintenance personnel.

- Prevention of Short Circuits: By isolating the conductors from other surfaces (like poles or towers), insulators prevent accidental short circuits and ground faults, thereby improving system reliability.

- Mechanical Support: Insulators provide the necessary mechanical support to hold conductors in place under normal conditions and during extreme weather (such as wind or storms).

- Durability / Long Lifespan: Insulators made from materials like porcelain or composite materials have a long lifespan and are resistant to wear and tear, reducing maintenance needs.

- High Voltage Handling: Insulators are designed to withstand high voltage stresses without breaking down, ensuring the smooth transmission of electricity over long distances.

- Cost-Effective: Especially for lower-voltage systems, insulators like pin and shackle types are relatively inexpensive, making them a cost-effective solution for power transmission.

- Various Designs: The availability of different types of insulators (pin, suspension, strain, etc.) allows for flexibility in design and application, catering to different voltage levels and mechanical requirements.

Disadvantages of Insulators in Overhead Lines:

- Vulnerability to Environmental Factors: Insulators can be susceptible to damage from harsh environmental conditions, such as lightning strikes, pollution, salt accumulation (in coastal areas), or extreme weather, which can degrade their effectiveness over time.

- High Maintenance in Some Cases: In regions with high pollution, insulators can accumulate dirt, moisture, and salt, which can reduce their insulating properties and may require frequent cleaning or replacement.

- Breakage Risk: Insulators made of materials like porcelain or glass are fragile and can break if subjected to mechanical stress, high winds, or physical impacts. Broken insulators can cause power outages and require costly replacements.

- Initial Cost for High Voltage Lines: While lower-voltage insulators are cost-effective, the cost of high-voltage insulators (like suspension or string insulators) can be relatively high, especially when a large number of insulators are required for long-distance transmission.

- Limited Flexibility in Certain Conditions: Some types of insulators, like pin insulators, are less suitable for areas with high mechanical load or in situations requiring flexibility (e.g., in areas with heavy winds or seismic activity).

- Weight and Size: Some types of insulators, particularly those made of porcelain or glass, can be heavy and bulky, making them difficult to handle and install. This is less of an issue with lighter polymer insulators.