Energy Meter Definition:

An electrical energy meter is a measuring device that quantifies the amount of electrical energy consumed by a residence, business, or electrical appliance over a specific period, typically measured in kilowatt-hours (kWh); Electric utility companies use these meters to determine the amount of electricity delivered to customers for billing purposes and ensuring fair and precise energy consumption monitoring.

Construction of Single phase energy meter:

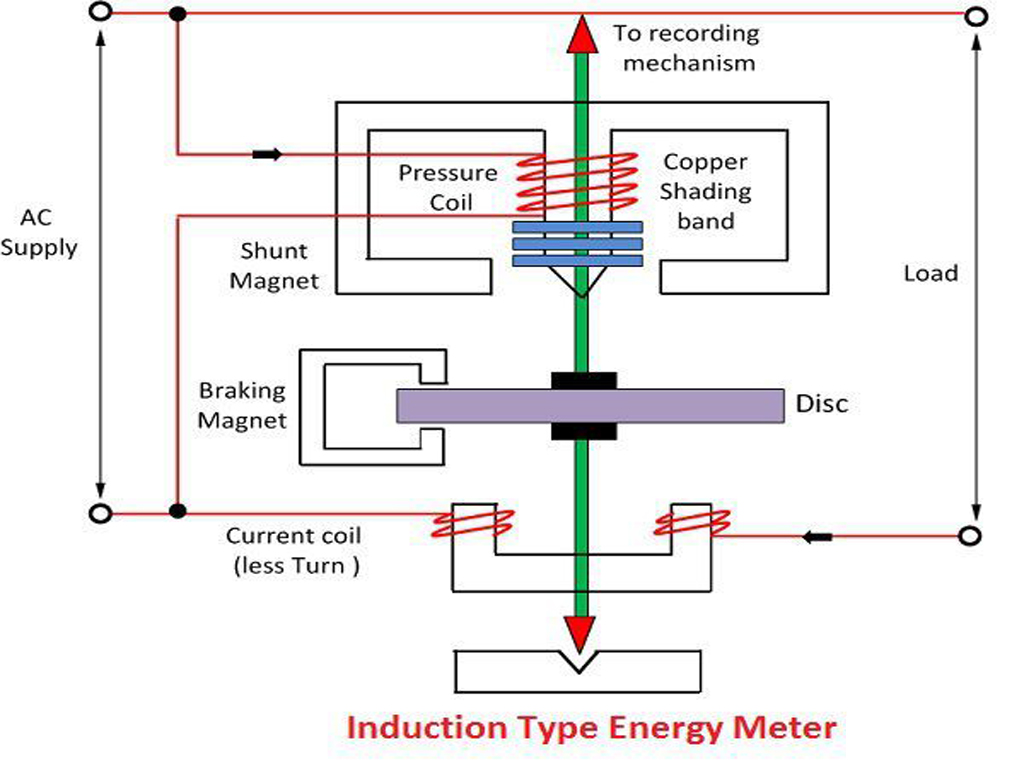

The construction of the single phase energy meter is shown in the figure below.

The energy meter has four main parts. They are the

- Driving System

- Moving System

- Braking System

- Registering System

Driving System:

This system consists of two electromagnets:

- Current Coil (Series Magnet or Shunt Resistor): Carries the load current. The current coil is connected in series with the load. When the current passes through the coil, it generates a magnetic field that interacts with the magnetic field from the potential coil, creating a torque that drives the moving system.

- Voltage Coil (Potential Coil) / Pressure Coil (Shunt Magnet): Connected across the voltage supply. This coil is connected across the supply voltage. The potential coil generates a magnetic field that interacts with the current coil to produce torque. It is responsible for driving the rotation of the disk.

These electromagnets create magnetic fields that interact to produce a driving torque.

Moving System:

- The moving system is responsible for physically rotating or moving in response to the energy consumption. This system converts the torque from the driving system into mechanical movement.

- This includes an aluminum disc mounted on a spindle.

- The disc is positioned in the air gap between the electromagnets.

- The interaction of the magnetic fields induces eddy currents in the disc, this eddy current is cut by the magnetic flux. The interaction of the flux and the disc induces the deflecting torque causing it to rotate.

When the devices consume power, the aluminium disc starts rotating, and after some number of rotations, the disc displays the unit used by the load. The number of rotations of the disc is counted at particular interval of time. The disc measured the power consumption in kilowatt hours.

Braking System:

- The braking system ensures that the moving system does not spin too freely and stabilizes the disk’s rotation, making the measurement more accurate and steady.

- Magnetic Braking Mechanism: A permanent magnet is used to create a braking torque. These permanent magnet is usually used to apply a braking force to the rotating disk. This braking mechanism is designed to ensure that the disk’s rotation is proportional to the power consumption.

- This torque opposes the rotation of the aluminum disc, ensuring that the disc’s speed is proportional to the power consumed. The magnetic brake creates a drag force on the rotating disk, slowing it down to a controlled speed. This controlled movement helps ensure that the disk rotates in a way that is proportional to the energy consumption over time.

- This system creates accuracy in the meter.

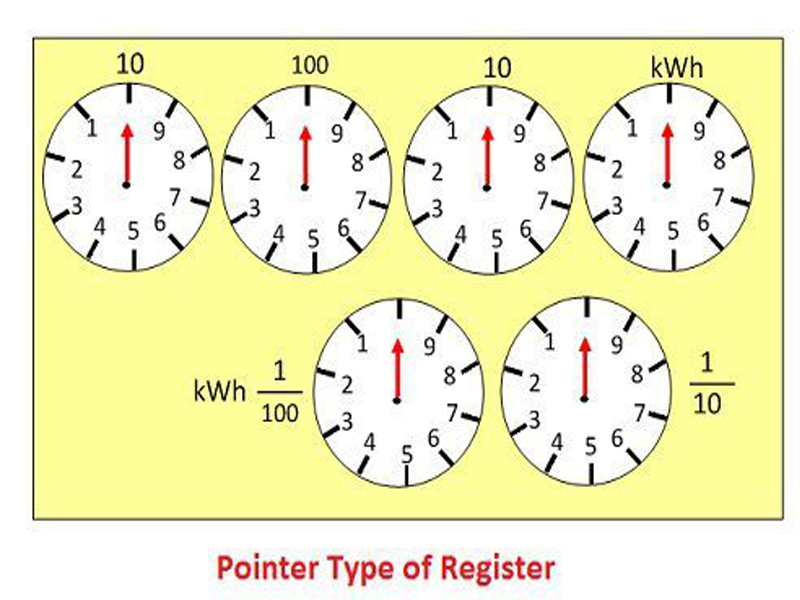

Registering System:

- This mechanism records the number of rotations of the aluminum disc.

- The rotations are proportional to the energy consumed.

- Gears and dials or a digital display are used to show the total energy consumption in kilowatt-hours (kWh).

- Register Mechanism: This is typically a set of mechanical dials or a counter that registers the energy consumed. In older electromechanical meters, this system consists of rotating dials or a mechanical counter that tracks the number of rotations of the disk.

- Digit Display (in digital meters): In modern digital meters, an electronic register displays the energy consumed in numerical format, such as kWh.

- As the disk rotates, it drives the register mechanism, which accumulates the number of rotations. Each rotation corresponds to a specific amount of energy consumption. The register system records this data and presents it to the user, either via dials or a digital display.

Working principle of the single phase Energy Meter :

The working principle of a single phase energy meter is based on the interaction of magnetic fields generated by voltage and current coils. The voltage coil is connected across the supply voltage, and the current coil is connected in series with the load. These coils produce magnetic fluxes that interact, creating a torque on a rotating disk. The speed of the disk’s rotation is proportional to the instantaneous power consumption, which is the product of voltage, current, and power factor. A magnetic braking system ensures steady rotation, preventing excessive speed. The rotating disk drives a registering mechanism, which records the total energy consumed, typically displayed in kilowatt-hours (kWh). This system provides an accurate measurement of energy usage by accumulating power over time.

Energy Calculation:

- The energy consumed over time is the integral of the instantaneous power, which is the product of voltage and current. The energy meter continuously accumulates this energy over a period of time.

- The formula for instantaneous power is:

P(t)=V(t)×I(t)×cos(ϕ)

Where:

- V(t) is the instantaneous voltage,

- I(t) is the instantaneous current,

- cos(ϕ) is the power factor, which accounts for the phase difference between voltage and current.

- The energy meter continuously integrates this power over time to measure the total energy (in kWh) consumed.

Modern Energy Meters:

- Modern digital energy meters work on a different principle. They use electronic components to sample voltage and current, calculate power, and digitally record energy consumption. They offer advantages like increased accuracy, remote reading, and advanced features like time-of-use metering.

- While the electromechanical meter is a classic design, modern energy meters increasingly use digital technology.

- Digital meters use electronic components to measure and record energy consumption.

- Smart meters take this even further, providing features like remote reading and two-way communication with utility companies.

Related Terms:

- Creeping in Energy Meter

- Three Phase Energy Meter

- Difference Between Wattmeter & Energy Meter

- Q Meter

- Electromagnetic Flow Meter

- Smart Prepaid meter