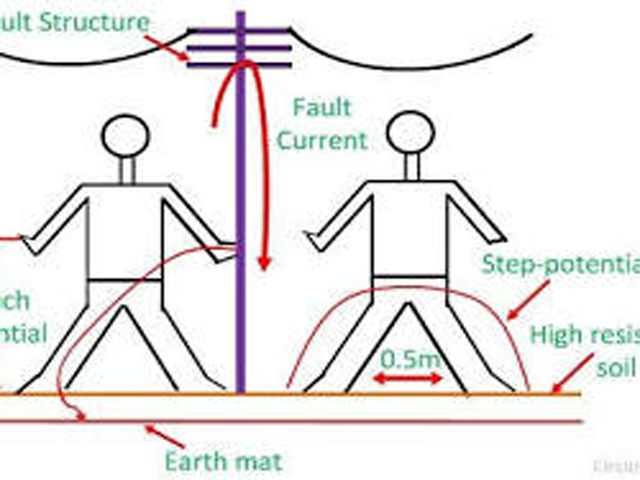

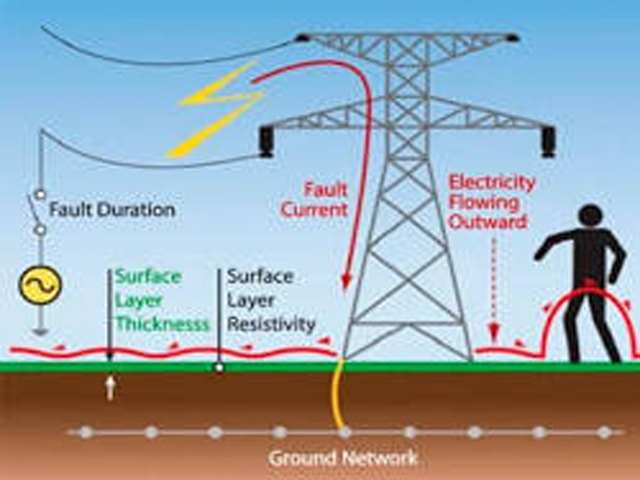

In electrical substations, step potential and touch potential are terms related to the safety of personnel in the event of an electrical fault, particularly during ground fault conditions. These potentials arise due to differences in voltage at different points on the ground around the substation, and they are important for preventing electric shock hazards.

Step Potential:

- Definition: The voltage difference between two points on the ground that are a step’s distance apart (typically about 1 meter) where a person might be standing.

- Cause: It occurs when there’s a fault in the system, like a short circuit, and current flows into the ground. This creates a voltage gradient on the ground surface.

- Hazard: When a fault occurs, current flows into the earth, creating a voltage gradient. If a person walks near the fault point, their feet may be at different potentials, leading to current flowing through their body.

- Risk: The higher the voltage difference, the greater the risk of electric shock.

Touch Potential:

- Definition: Touch potential refers to the voltage difference between a grounded object (like a fence, equipment, or the substation’s structural parts) and the ground where a person might be standing.

- Cause: This happens when there’s a fault and part of the equipment becomes energized, such as a metal enclosure or grounding system. A person who touches this energized object while standing on the ground could experience an electric shock.

- Hazard: Touch potential becomes dangerous if the object someone is touching is energized, causing current to flow through the person’s body to the ground.

Safety Measures:

To mitigate the risks of step and touch potentials, substations employ various safety measures:

- Grounding grids: Provide a low-impedance path for fault current, reducing voltage gradients.

- Bonding: Connect all metallic objects to the grounding grid, ensuring they are at the same potential.

- Insulation: Use insulating materials for equipment and surfaces to prevent contact with energized parts.

- Barriers: Restrict access to areas with high voltage gradients.

- Signage: Warn personnel about potential hazards.

- Training: Educate workers about safety procedures and how to recognize and avoid hazards.

Additional Considerations:

- Soil resistivity: Affects the voltage gradient and the effectiveness of grounding.

- Fault current magnitude: Higher fault currents lead to higher voltage gradients.

- Duration of fault: The longer the fault duration, the greater the risk.

By understanding the concepts of step and touch potential and implementing appropriate safety measures, electrical substations can be made safer for personnel.

GIS Electrical substation:

A gas-insulated substation (GIS) is a high-voltage substation in which the major conducting structures are contained within a sealed environment with a dielectric gas known as SF6, or sulfur hexafluoride gas as the insulating medium.

GIS technology is used in substations where space is limited, as it requires less space than traditional air-insulated substations. It is also used in areas where environmental conditions are harsh, as the sealed environment protects the equipment from the elements.

GIS technology has been used in Japan since the 1960s, and has been adopted by other countries over the years. It is now used in about 20% of new substations in countries with severe space limitations.

GIS technology is more expensive than traditional air-insulated substations.

Advantages:

- Compact Size: GIS equipment is housed in metal enclosures, reducing the need for large physical space compared to traditional air-insulated substations (AIS).

- High Reliability: The use of SF6 gas as an insulating medium allows for better performance in extreme weather conditions, and the sealed environment reduces the chances of faults or failures.

- Safety: GIS substations are enclosed, which improves safety for both operators and the surrounding environment, as the equipment is protected from external factors such as dust, moisture, and physical damage.

- Reduced Maintenance: Because of the sealed and protected nature of GIS substations, they often require less maintenance and have a longer operational life compared to traditional air-insulated systems.

- Environmental Considerations: SF6, though highly effective, is a greenhouse gas, so its use and disposal require proper management to minimize environmental impact. Some advances are working on alternatives to SF6 to make GIS more eco-friendly.

- Applications: GIS substations are often used in urban areas, industrial facilities, and places where space is at a premium. They’re also favored for offshore installations, such as those for renewable energy.

GIS technology is a good choice for substations in urban areas, where space is at a premium. It is also a good choice for substations in harsh environments, where the equipment needs to be protected from the elements.