Definition of Solar Electrical systems:

Solar Electrical Energy refers to the energy generated from sunlight and converted into electricity using solar panels (photovoltaic cells) or solar thermal systems. In photovoltaic systems, the sunlight is directly converted into electricity, while in solar thermal systems, the sunlight is used to heat a fluid that drives a turbine to generate electricity.

This type of energy is renewable, sustainable, and has gained widespread use as a cleaner alternative to fossil fuels.

PV system:

A photovoltaic (PV) system is able to supply electric energy to a given load by directly converting solar energy through the photovoltaic effect. The system structure is very flexible. PV modules are the main building blocks; these can be arranged into arrays to increase electric energy production.

Types of solar systems:

At a high level, there are three types of solar power system:

- On-grid solar.

- Off-grid solar.

- Hybrid solar.

Constructional Parts of Solar Electrical Energy System:

Solar Panels (Photovoltaic Cells):

- These are the most critical part of a solar power system. They are made up of many smaller solar cells that convert sunlight into electricity through the photovoltaic effect.

- Typically made from semiconductor materials like silicon, the cells generate direct current (DC) electricity when exposed to sunlight.

Inverter:

The inverter converts the DC electricity generated by the solar panels into alternating current (AC) electricity, which is used in homes and businesses.

Charge Controller (in off-grid systems):

In off-grid solar power systems, a charge controller manages the flow of electricity to and from the batteries. It ensures that the batteries do not overcharge and that the system works efficiently.

Batteries (in off-grid systems):

These store excess electricity generated during the day for use at night or during periods of low sunlight. Batteries are typically used in off-grid systems or hybrid systems (grid-tied with storage).

5. Mounting System:

The mounting system holds the solar panels in place. It can be fixed or adjustable to track the sun’s movement (solar trackers), optimizing energy collection. Solar modules are usually mounted on roofs. If roof area is not available, PV modules can be pole-mounted, ground-mounted, wall-mounted.

6. Wiring and Connections:

These are needed to connect the various components of the solar power system, ensuring proper flow of electricity.

Working Process:

- Absorption of Sunlight: Solar panels consist of photovoltaic cells that absorb sunlight. When sunlight hits these cells, it excites electrons, creating an electric current.

- Generation of Direct Current (DC): The photons from sunlight knock electrons loose from atoms in the semiconductor material of the solar cells. This generates direct current (DC) electricity.

- Conversion to Alternating Current (AC): The DC electricity produced is fed into an inverter, which converts it into alternating current (AC) electricity. AC is the type of electricity used in most homes and businesses.

- Power Distribution: The AC electricity is then distributed to power appliances and systems in the building or is sent back into the grid (in grid-tied systems). In off-grid systems, the electricity may be stored in batteries for later use.

- Grid Connection (if applicable): In a grid-tied system, the excess power that is not immediately used can be sent back to the electrical grid, often resulting in credits or payments through net metering.

Solar electrical energy systems can vary in size and complexity, from small rooftop panels powering a home to large-scale solar farms that feed electricity into the grid.

Types of solar cells:

There are several types of solar cells, each with unique properties and applications. These variations are based on the materials used in their construction and the way they capture and convert sunlight into electricity. Here’s an overview of the main types:

1. Monocrystalline Silicon Solar Cells

- Definition: Made from a single continuous crystal structure.

- Characteristics:

- High efficiency (typically 15-20%).

- Long lifespan (usually 25+ years).

- Higher cost due to the production process.

- Appearance: Dark black color with a uniform, smooth look.

- Best For: Residential and commercial installations where space is limited and high efficiency is needed.

2. Polycrystalline Silicon Solar Cells (or multicrystalline)

- Definition: Made from silicon crystals that are melted together and poured into molds.

- Characteristics:

- Slightly lower efficiency (typically 13-17%) compared to monocrystalline.

- More affordable due to simpler manufacturing.

- Slightly shorter lifespan than monocrystalline.

- Appearance: Blue color with a grainy or speckled texture.

- Best For: Budget-conscious residential and commercial systems, especially where space is less of a concern.

3. Thin-Film Solar Cells

- Definition: Made by layering photovoltaic material (such as cadmium telluride, amorphous silicon, or copper indium gallium selenide) onto a substrate (like glass, plastic, or metal).

- Characteristics:

- Less efficient (typically 10-12%) compared to crystalline silicon.

- Flexible and lightweight, making them suitable for unconventional surfaces (roofs, windows, etc.).

- Lower production costs and versatility in design.

- Appearance: Thin, flexible, often black or dark blue panels.

- Best For: Large-scale solar projects, integration into building materials (like solar windows or solar roof tiles), or areas where flexibility and lightweight panels are required.

4. Perovskite Solar Cells

- Definition: Made from a type of material known as perovskite (a compound with a unique crystal structure).

- Characteristics:

- High efficiency potential (around 20-25%) and is rapidly improving.

- Lower cost of production than traditional silicon-based solar cells.

- Still in the research and development phase, but it holds promise for future commercial use.

- Appearance: Typically small, with a variety of colors.

- Best For: Research purposes and potential future commercialization as technology matures.

5. Organic Photovoltaic Cells (OPVs)

- Definition: Made from organic materials (carbon-based) that can conduct electricity when exposed to light.

- Characteristics:

- Low efficiency (typically 5-10%).

- Flexible and lightweight.

- Relatively low production cost but currently not as durable as other types.

- Appearance: Flexible and available in a range of colors.

- Best For: Small-scale applications, such as powering small devices, or emerging technologies like solar-powered clothing or flexible panels.

6. Concentrated Photovoltaic Cells (CPVs)

- Definition: Use lenses or mirrors to concentrate sunlight onto small, high-efficiency solar cells.

- Characteristics:

- Very high efficiency (typically 30-40% or more) due to concentrated light.

- Require direct sunlight and tracking systems to follow the sun’s movement.

- Expensive, and mostly used for large-scale commercial or utility-scale projects.

- Appearance: Often look like clusters of small cells with lenses or mirrors.

- Best For: Large-scale solar power plants, particularly in regions with high direct sunlight

Six Main components of a solar panel

- Solar photovoltaic cells.

- Toughened Glass – 3 to 3.5mm thick.

- Extruded Aluminum frame.

- Encapsulation – EVA film layers.

- Polymer rear back-sheet.

- Junction box – diodes and connectors.

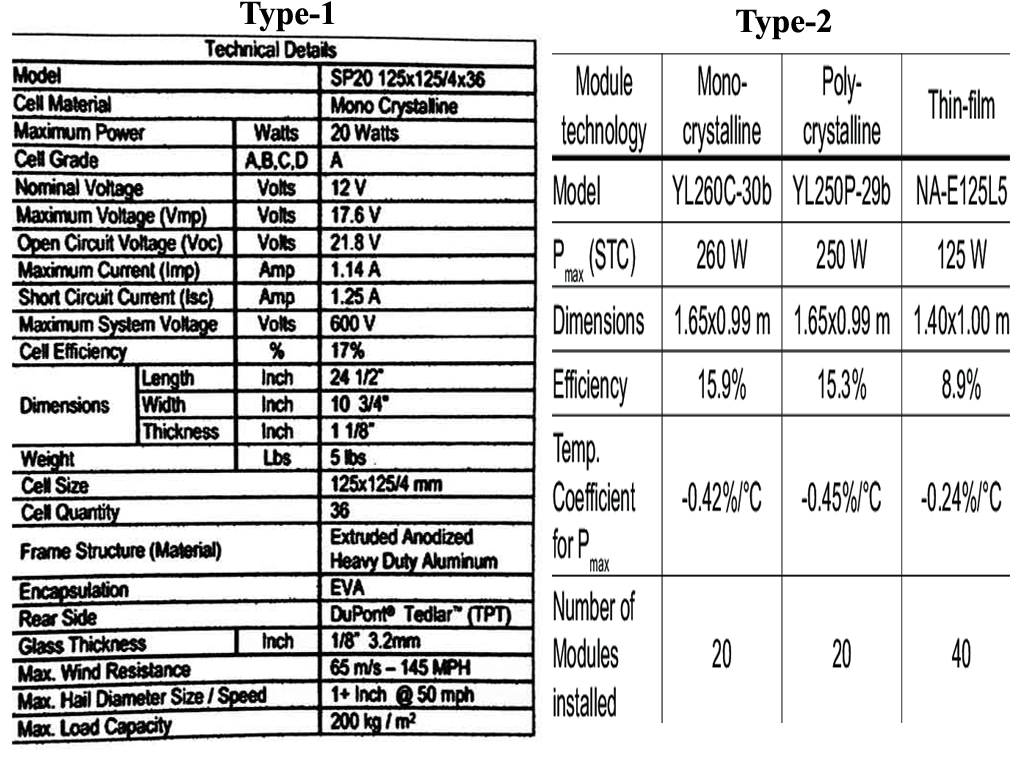

Solar Electrical specification:

The specifications of a solar electrical system can vary depending on the type and scale of the installation (residential, commercial, or industrial). However, here are some common key specifications you would find for a typical solar electrical system:

1. Solar Panels (Photovoltaic Modules)

- Type: Monocrystalline, Polycrystalline, Thin-film, or Bifacial.

- Power Output: Typically ranges from 250W to 400W per panel, depending on the panel size and efficiency.

- Efficiency:

- Monocrystalline: 15-22%

- Polycrystalline: 13-18%

- Thin-film: 10-12%

- Voltage: Usually around 18V to 22V (for standard 60-cell panels).

- Current: Typically ranges from 5A to 9A per panel.

- Size: Common panel sizes are 1.6m x 1m for 60-cell panels or 2m x 1m for 72-cell panels.

- Temperature Coefficient: Indicates how the efficiency drops as temperature increases (e.g., -0.4%/°C).

2. Inverter

- Type: String inverter, Microinverter, or Hybrid inverter.

- Power Rating: Typically between 1kW to 10kW for residential systems, but can go higher for commercial systems.

- Input Voltage Range: Varies, commonly between 150V to 600V DC.

- Output Voltage: Usually 120V or 240V AC for residential, or 380V/415V AC for commercial.

- Efficiency: 95%-98%, with higher efficiency in modern inverters.

- Grid Compatibility: Most inverters are grid-tied, but hybrid inverters can also work with battery storage systems.

3. Battery Storage (Optional for Off-grid/Hybrid Systems)

- Type: Lithium-ion (Li-ion), Lead-acid, or Flow batteries.

- Capacity: Measured in kilowatt-hours (kWh). Residential systems may range from 5kWh to 20kWh.

- Voltage: Typically 12V, 24V, or 48V depending on the system.

- Cycle Life: Lithium-ion batteries typically have a cycle life of 3,000-5,000 cycles; lead-acid batteries have fewer cycles (500-1,000 cycles).

- Charge/Discharge Efficiency: Generally 85%-95% for most systems.

4. Charge Controller (for Off-grid Systems)

- Type: PWM (Pulse Width Modulation) or MPPT (Maximum Power Point Tracking).

- Rated Current: Typically ranges from 10A to 60A, depending on system size.

- Voltage Compatibility: 12V, 24V, 48V (common voltages).

- Efficiency: MPPT controllers are typically 95%-98% efficient, while PWM controllers are less efficient (85%-90%).

5. Mounting System

- Material: Typically aluminum or galvanized steel for durability.

- Type: Fixed tilt or adjustable systems for tracking the sun’s movement.

- Angle: The optimal tilt angle depends on location but generally ranges between 20° to 40°.

6. Wiring and Connectors

- Wire Type: Solar-rated cables, often UL-listed, like PV1-F or THHN wires.

- Cable Size: Varies based on system size; common sizes are 10 AWG, 8 AWG, and 6 AWG.

- DC Disconnects and AC Disconnects: Used to isolate the solar array from the inverter or the grid for safety and maintenance.

7. System Monitoring

- Monitoring Type: Can be local (via a display on the inverter) or remote (via smartphone or web apps).

- Features: Performance tracking, energy production, efficiency metrics, and system diagnostics.

8. System Capacity and Output

- System Size: Residential systems typically range from 3kW to 10kW, while commercial and industrial systems may be much larger, up to several hundred kW.

- Energy Production: A 5kW system typically produces about 15-20 kWh per day depending on sunlight availability and geographical location.

9. Certifications

- IEC/UL Certification: Ensures that the system components meet global safety and performance standards.

- Warranty: Solar panels typically come with 20-25 years warranty, while inverters and batteries typically come with 5-10 years warranty.