Solar panels

Solar panels work by converting sunlight directly into electricity using a process called the photovoltaic (PV) effect. The word “photo” means light, and “voltaic” refers to electricity.

The Photovoltaic Effect in Solar Cells

A solar panels is made up of many small units called solar cells, which are typically made of silicon (a semiconductor material) and constructed with two different layers:

- N-type layer: Silicon is “doped” with impurities (like Phosphorus) to give it extra electrons, resulting in a negative charge.

- P-type layer: Silicon is doped with impurities (like Boron) to give it a deficiency of electrons (creating “holes”), resulting in a positive charge.

When these two layers are placed next to each other, they form an electric field, which acts like a one-way street for electrons.

The Conversion Process

- Light Absorption: When sunlight (made up of energy particles called photons) strikes the solar cell, the photons transfer their energy to the silicon atoms.

- Electron Excitation: This energy is enough to knock electrons loose from their atoms in the silicon material, creating a flow of free electrons.

- Current Flow: The electric field between the N-type and P-type layers pushes these free electrons in a specific direction—toward the N-type layer. Since electrons can only travel back to the P-type layer through an external circuit, this directed flow of electrons creates an electric current (specifically, Direct Current or DC).

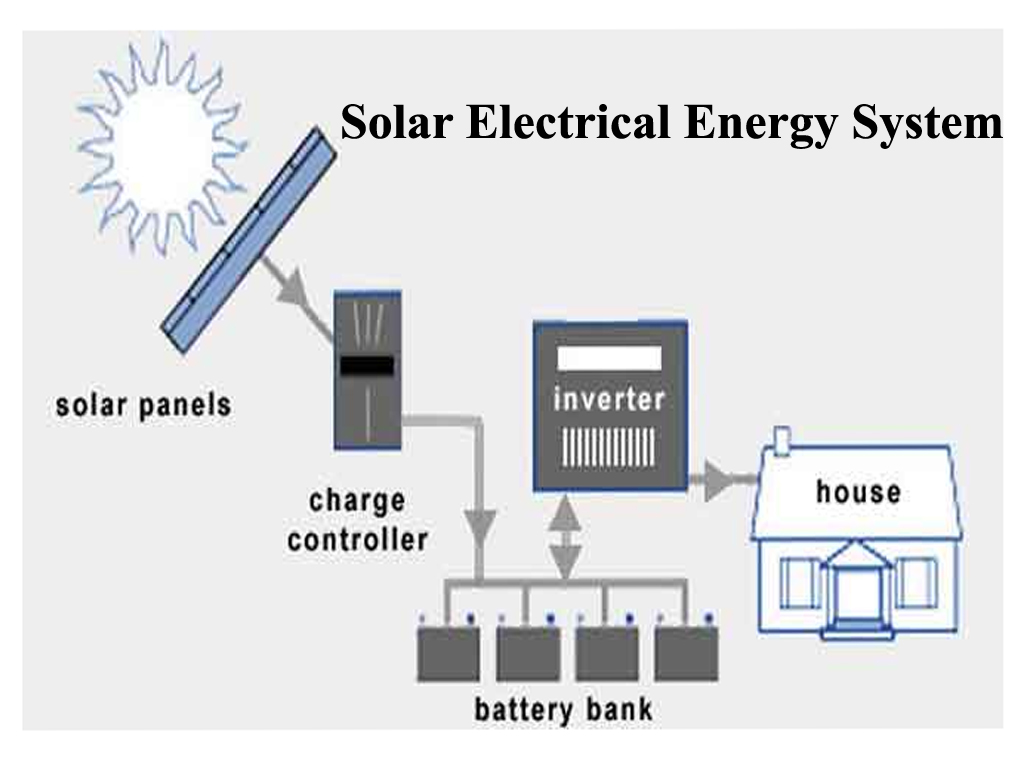

System Components for Usable Electricity

The DC electricity generated by the solar panels isn’t immediately usable by most household appliances, so it must be processed by other components:

- Solar Panels (PV Modules): Convert sunlight into DC electricity.

- Inverter: The direct current (DC) electricity from the panels is sent to an inverter, which converts it into Alternating Current (AC) electricity. AC is the standard type of electricity used by homes, businesses, and the public electric grid.

- Main Electrical Panel: The usable AC electricity is fed into your home’s main electrical panel (breaker box) and distributed to power your lights and appliances.

- Net Metering / Battery Storage:

- Excess Power to the Grid (Net Metering): If your solar panels produce more electricity than your home is currently using, the excess power is sent back to the utility grid, often earning you credits on your electricity bill.

- Battery Storage: For systems with batteries, the excess power is stored to be used later, such as at night or during a power outage.

What are Solar Panels Made of?

Solar panels are made up of several key components and materials that work together to turn sunlight into electricity. The core of the panel, responsible for converting sunlight into electricity via the photovoltaic effect, is typically made from silicon.

1. Solar Cells (the core component):

Solar Cells material usually silicon, a semiconductor that absorbs sunlight and releases electrons.

Types of silicon solar cells:

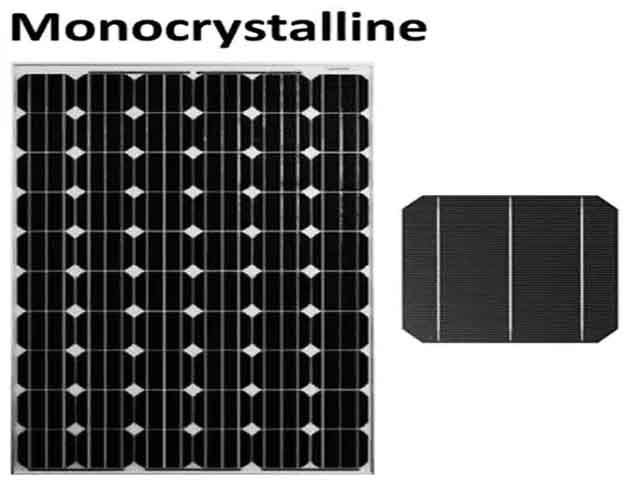

- Monocrystalline: Made from a single crystal of silicon. They’re dark black, highly efficient, and long-lasting. Panels using this are generally more efficient and appear uniform black.

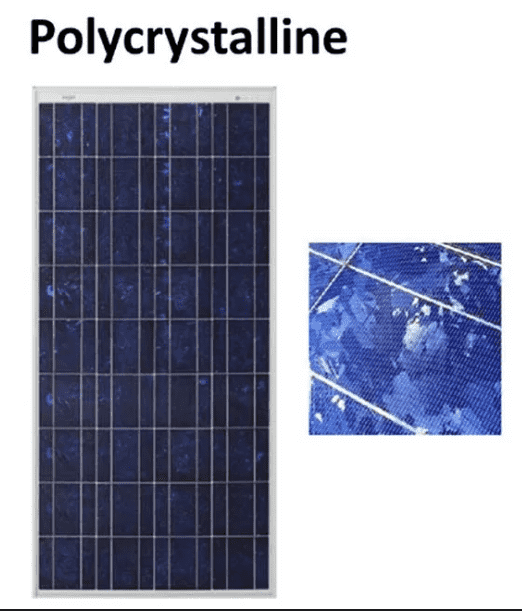

- Polycrystalline: Made from melted fragments of silicon. They’re bluish in color, slightly less efficient, but more affordable. Panels are slightly less efficient, have a lower manufacturing cost, and typically appear blue or speckled.

- Thin-film: Made from layers of materials like cadmium telluride (CdTe) or amorphous silicon (a-Si). Lightweight and flexible, but lower efficiency.

2. Protective Layers (The Shield):

- Glass Layer: Glass Layer material is tempered glass, This is the outermost layer and usually the heaviest part of the panel (up to 70-80% of the total weight). It must be highly transparent to allow maximum sunlight through while being strong enough to withstand hail, snow, and wind

- EVA Film (Encapsulant): Ethylene Vinyl Acetate (EVA) is a clear, rubber-like polymer film placed above and below the solar cells. When heated during manufacturing, it melts, laminates, and seals the cells, protecting them from moisture and vibration.

- Backsheet: This is the back layer of the panel, usually made of a durable polymer material (plastic, often containing fluoropolymers). It provides electrical insulation and protection from moisture and UV degradation on the backside.

Purpose: Protects the solar cells from weather (rain, hail, dust) while allowing sunlight to pass through efficiently. It’s durable, transparent, and often has an anti-reflective coating to capture more sunlight.

3. Structural Components (The Support)

These materials give the panel its rigidity and make it easy to install.

- Aluminum Frame: The sturdy frame surrounding the edge of the panel is made of aluminum alloy. Its purpose is to protect the glass edges, provide structural support, and allow the panel to be securely mounted to a racking system.

- Junction Box: A weatherproof box mounted on the back of the panel, containing the electrical wiring connections and bypass diodes to connect the panel to the rest of the solar system.

4. Encapsulant Layers:

Encapsulant layers are protective, transparent polymer films used to secure and safeguard solar cells from environmental damage. They sandwich the solar cells between layers of glass and a backsheet, protecting them from moisture, dirt, and pollutants while also improving mechanical stability and light transmission. Material is the Ethylene-vinyl acetate (EVA).

Encapsulant layers Seals and cushions the solar cells, holding them in place and protecting them from moisture and vibration.

5. Back Sheet:

Black sheet Material is Durable polymer or plastic (often PVF or PET). Purpose of black sheet is bottom layer of the panel that provides insulation, protects against UV rays, and prevents damage from the environment.

Types of silicon solar cells:

1. Monocrystalline Solar Cells (Mono-Si)

These cells are made from a single, highly pure silicon crystal grown from a seed crystal in a vat of molten silicon (Czochralski process). The uniform structure allows electrons to move more freely, resulting in higher efficiency.

| Feature | Details |

| Material | Single-crystal silicon ingot. |

| Appearance | Uniform dark black color with rounded corners. |

| Efficiency | Highest, often 20%–25%+. |

| Manufacturing | High-purity, energy-intensive process; creates some silicon waste. |

| Lifespan | Longest, typically 25–30+ years. |

Advantages

- Highest Efficiency: Excellent performance, meaning fewer panels are needed.

- Space Efficient: Ideal for installations with limited roof or ground space.

- Aesthetics: Sleek, uniform black appearance is often preferred by homeowners.

- Better in Low Light: Performs slightly better in low-light or cloudy conditions than polycrystalline.

Disadvantages

- Highest Cost: Most expensive due to the complex manufacturing process.

- Performance in High Temperatures: Efficiency can drop slightly more than other types when temperatures are very high (though performance is still high overall).

Applications

- Residential Rooftops with limited space.

- Commercial Buildings where high power output per square meter is essential.

- Solar Farms prioritizing maximum energy density.

2. Polycrystalline Solar Cells (Poly-Si or Multicrystalline)

Polycrystalline cells are made by melting raw silicon fragments together and pouring the molten silicon into a square mold, which is then cooled and sliced into wafers. This process results in multiple crystals, giving the cells a less uniform look.

| Feature | Details |

| Material | Multiple silicon crystals fused together. |

| Appearance | Bluish, speckled, non-uniform look (due to multiple crystals). |

| Efficiency | Moderate, typically 15%–17%+. |

| Manufacturing | Simpler, faster, and less waste compared to monocrystalline. |

| Lifespan | Long, typically 25–30 years. |

Advantages

- Lower Cost: Less expensive to manufacture, making them more budget-friendly.

- Lower Waste: The manufacturing process uses silicon more efficiently, with less material waste.

- Wider Application: A cost-effective choice for large installations with ample space.

Disadvantages

- Lower Efficiency: Requires more surface area to produce the same power output as monocrystalline.

- Lower Aesthetics: The speckled, blue color is often considered less visually appealing.

Applications

- Residential and Commercial installations where cost is a higher priority than maximum space efficiency.

- Large-scale Solar Farms where land is not a constraint.

3. Thin-Film Solar Cells (TFSC)

Thin-film technology involves depositing one or more very thin layers of photovoltaic material (such as amorphous silicon (a-Si), Cadmium Telluride (CdTe), or Copper Indium Gallium Selenide (CIGS)) onto a substrate like glass, plastic, or metal.

| Feature | Details |

| Material | Amorphous silicon, CdTe, CIGS, etc. Deposited in thin layers. |

| Appearance | Uniform, typically black and very sleek; can be flexible. |

| Efficiency | Lowest, typically 10%–13%, though newer technologies are improving. |

| Manufacturing | Cheapest production process; uses less material. |

| Lifespan | Shorter than crystalline types, typically 10–20 years. |

Advantages

- Most Affordable: Lowest manufacturing cost.

- Flexible and Lightweight: Can be integrated into building materials or used on curved surfaces.

- Better in High Temperatures and Low Light: Their performance is less affected by high heat and they can be highly effective at capturing diffuse light.

- Aesthetics: Very thin, low-profile, and uniform appearance.

Disadvantages

- Lowest Efficiency: Requires significantly more space to achieve the same power output as crystalline panels.

- Shorter Lifespan/Lower Durability: Generally less durable than crystalline panels.

- Material Concerns: Some types use materials like Cadmium Telluride, which requires careful recycling and disposal.

Applications

- Large-scale Utility projects where space is plentiful and low cost is paramount.

- Building Integrated Photovoltaics (BIPV), such as solar shingles or semi-transparent glazing.

- Mobile/Portable Applications, due to their lightweight and flexibility (e.g., camping gear, small electronics, RVs, boats).

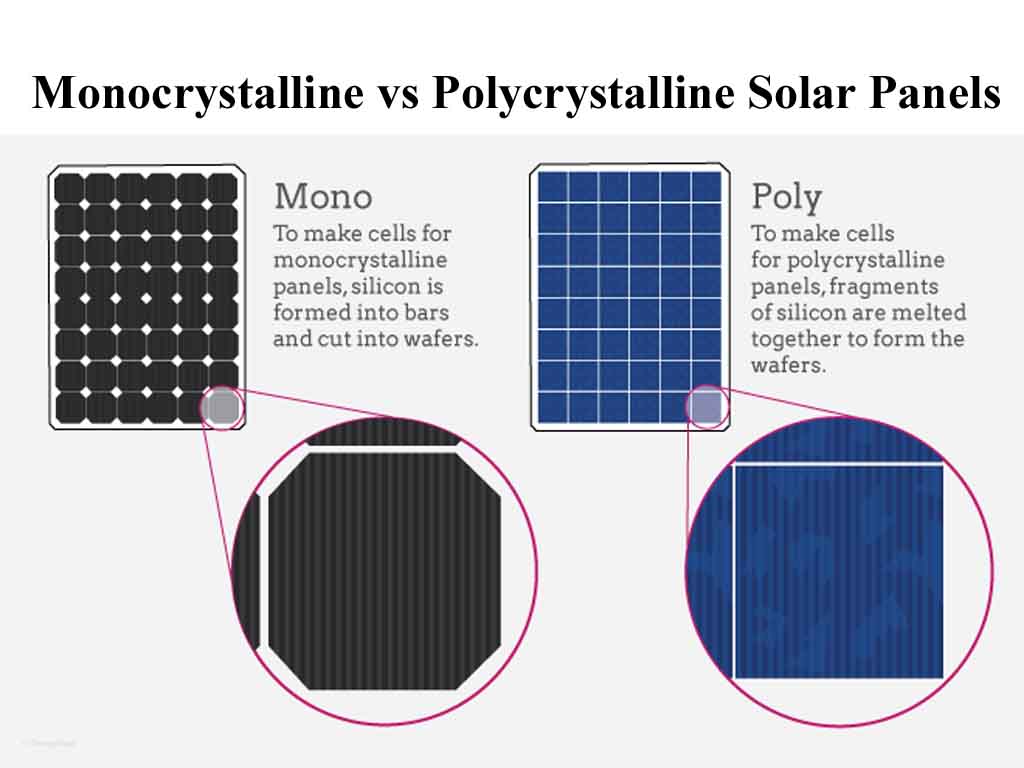

Monocrystalline vs Polycrystalline Solar Panels:

The key differences between monocrystalline and polycrystalline solar panels lie in their silicon cell structure, which impacts their efficiency, cost, and appearance.

Monocrystalline panels are made from a single, pure silicon crystal, while polycrystalline panels are made from multiple silicon crystal fragments melted together.

Comparison Table

Key Differences Explained

1. Cell Structure and Efficiency

- Monocrystalline: The cell is cut from a single, continuous crystal of silicon ingot. This uniform structure allows electrons to move more freely, resulting in higher efficiency and greater power output per square foot. They are considered the premium option.

- Polycrystalline: The cell is made from multiple silicon fragments melted together. The numerous crystal boundaries within the cell slightly restrict electron movement, leading to lower efficiency compared to mono panels.

2. Cost and Manufacturing

- Monocrystalline: The process of creating a single, pure silicon crystal is more complex and results in some silicon waste, making these panels more expensive to produce.

- Polycrystalline: The manufacturing process is simpler, using molten silicon cast into a mold and allowing for the reuse of silicon fragments, which makes them less expensive upfront.

3. Aesthetics

- Monocrystalline: Their single-crystal structure gives them a uniform, sleek black appearance, which many homeowners find more aesthetically pleasing.

- Polycrystalline: Their multi-crystal structure gives them a distinctive dark blue, slightly speckled look.

Related Posts:

Step-by-Step Guide to Controlling a DOL Starter Motor with Solar Power

Basic Concept of Hybrid solar system

What Is an Off-Grid Solar System and How Does It Work?

The Complete Guide to Installing an On-Grid Solar System

Battery Storage and Inverter Technologies in Solar Home Systems

Solar System MCQ -01

Solar System MCQ-001