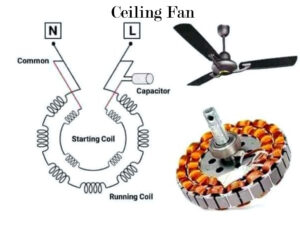

Ceiling Fan

A ceiling fan is a device suspended from the ceiling of a room, with hub-mounted rotating blades that circulate the air, thereby producing a cooling or DE stratification effect. Most ceiling fans have an electrical switch that allows one to reverse the direction of rotation of the blades.

Ceiling Fan Construction:

A ceiling fan consists of several key components that work together to provide air circulation.

Motor:

- The motor is the heart of the fan, responsible for turning the blades. It is usually an AC (alternating current) or DC (direct current) motor, depending on the fan’s design. The motor is housed in the motor housing or canopy, which is mounted to the ceiling.

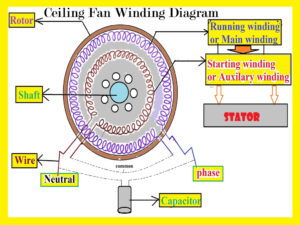

- The motor consists of:

- Stator: The stationary part of the motor that generates a magnetic field.

- Rotor: The rotating part of the motor, which is connected to the fan blades.

- Bearings: Support the rotor and allow it to rotate smoothly.

Blades:

- The fan blades are attached to the motor’s rotor. They are typically made from materials such as metal. The blades are angled (pitched) to move air effectively when they spin.

- The number of blades can vary, but most ceiling fans have 3, 4, or 5 blades. The design of the blades influences the airflow and noise level.

Blade Holder/Brackets:

- Blade brackets hold the blades securely in place. These brackets are attached to the rotor of the motor.

Canopy:

- The canopy is the cover that hides the motor housing and connects the fan to the ceiling. It also helps secure the fan and houses any electrical connections.

Pull Chain or Remote Control:

- The pull chain is used in traditional fans to control the fan’s speed and sometimes to reverse the direction of the blades.

- Modern fans often use remote controls or wall-mounted controls that allow users to adjust the speed, direction, and lighting.

Capacitor:

- Capacitors are used in the motor circuit to control the speed of the fan and ensure efficient performance. In some models, capacitors help reverse the motor direction for winter operation.

Lighting Kit (optional):

- Many ceiling fans come with an integrated lighting kit that includes light bulbs, usually LED or CFL. The lighting kit is mounted at the bottom of the fan assembly and can be controlled by a separate switch or integrated into the fan’s control system.

Working Principle of a Ceiling Fan:

The working principle of a ceiling fan is based on electromagnetic induction and air movement.

When you turn on the fan, electrical energy flows through the wires and into the motor. The motor receives an electric current, which interacts with the magnetic field produced by the stator. The motor generates a magnetic field that causes the rotor (the rotating part of the motor) to spin. The rotor is connected to the fan blades, so when the rotor turns, the blades also rotate.

As the fan blades rotate, they displace air, pushing it in the direction of the blade’s motion. The shape and angle of the blades (the pitch) determine how much air is moved and the effectiveness of the fan.

Job Viva Questions & Answer:

Q-01: What length down rod should be used with a ceiling fan?

Answer: For optimum performance, ceiling fan blades should be at least 2.4 m from the floor but no higher than 2.8 m in order to best cool a room.

Q-02: What is the difference between a four-blade and a five-blade ceiling fan?

Answer: The primary difference between 4-blade and 5-blade is appearance. For fans that use identical motors and blade designs, a 4-blade fan will move a bit more air than a 5-blade fan. The reduced weight allows the motor to spin a bit faster increasing the amount of air moved.

Q-03: Why is the fan running slowly?

Answer: A faulty capacitor may cause a ceiling fan to run slowly or quit running altogether. To replace capacitor follow the instructions below. The capacitor should be replaced by an electrician:

- There are three screws that hold the light kit or switch or housing cap to the bottom of the fan.

- Remove these screws and take the light kit or housing cap off. The capacitor needs to be identified for replacement by noting the numbers and letters on the side of the capacitor; ex. numbers followed by the letters “uf” (1.5uf). The voltage will need to be identified also.

Q-04: Which wire is used for light or fan connection?

Answer: 1.5 RM

Q-05:How many coils are in a ceiling fan?

Answer: A ceiling fan motor generally contains two coils, Running coil and Starting coil. The main difference between a running coil and a starting coil is the number of turns of wire used and the resistance of each coil.

Q-06: The starting coil of the fan has more resistance or does the running coil?

Answer: Starting coil. Because the motor-driven device draws a lot of current at start-up, the resistance of the starting coil must be high. The starting coil is made of fewer turns of thinner wire than the running coil. The starting coil has higher resistance and lower inductance (L) than the running coil.

Q-07: Why capacitor is connected in series with starting coil of the fan?

Answer: A capacitor is connected in series with the starting coil of a fan to create a phase angle in the current of the two windings, which makes the fan’s rotor rotate, When the fan is powered on, the two windings would normally be connected in parallel and generate fluxes in phase, which would prevent the fan from turning. Because this capacitor is used for the purpose of generating torque or rotation of the motor AC current creates an equal and opposite magnetic field, there is no net force to rotate the fan or motor.

Q-08: Which type of A.C motor is used in the fan (ceiling fan, exhaust fan, padestal fan, bracket fan etc) which are find in the houses ?

Answer: Its Single Phase induction motor which mostly squirrel cage rotor and are capacitor start capacitor run.

Q-09: What is the function of capacitor in ceiling fan?

Answer: It creates phase difference between running and starting winding and provides starting torque.

Q-10: Name the insulation used in ceiling fan?

Answe: Rubber, Paper, Varnish, Bakelite etc

Q-11: What are the Rating of ceiling fan?

Answe: (i) 60W, 350rpm, 1-phase, 230V, 50Hz

(ii) 45W, 350rpm, 1-phase, 230V, 50Hz

Q-12: What happen if the capacitor terminals interchanged of ceiling fan?

Answe: There will be no effect on fan performance.

Q-13: What happen if the running winding are terminals interchanged of ceiling fan?

Answe: Fan will running with opposite direction

Q-14: We can start a ceiling fan without using capacitor, Yes or Not?

Answe: Yes, By providing a torque in any direction but its rotate slowly.

Q-15: What is the function of speed regulator / fan Dimmer

Answe: It controls the input voltage of the motor. Thus controls the flux produced hence speed controlled.

Q-16: Which motor used in ceiling fan?

Answe: It is single phase squirrel cage permanent capacitor induction motor.

Q-17: What is the capacity of a capacitor of a ceiling fan?

Answer: 2.5 µF

Q-18: What is the capacity of a capacitor of a table fan?

Answer: 2.0 µF to 2.5 µF

Q-19: What is the capacity of a capacitor of a Exhaust fan?

Answer: 2.0 µF.

Q-20: Who invented Ceiling Fan?

Answer: The electrically-powered ceiling fan was invented in 1882 by Philip Diehl

Q-21: What type of bearings are used in ceiling fans?

Answer: Ceiling fans typically use ball bearings in their motors, but the specific type can vary depending on the fan’s design and quality.

Ball bearings are used between the hub and axial of ceiling fans because it reduces the friction between the rotating hub and the fan’s static axial to a much greater extent than direct contact, which can generate large amounts of heat. ball bearings (either shielded or deep groove) are the most common type of bearing used in modern ceiling fans because they offer a good balance of performance, durability, and cost-effectiveness.

Q-22: Tell some name of most common types of bearings used in ceiling fans.

Answer:

- Shielded Ball Bearings: They are sealed or shielded to protect the internal ball bearings from dust, dirt, and moisture. Shielded ball bearings are relatively low-maintenance, but they might need to be lubricated occasionally, depending on the fan’s design.

- Sintered Sleeve Bearings: Some lower-cost or older ceiling fan models may use sintered sleeve bearings (also called bushing bearings).These are made from a porous material that holds lubricant and gradually releases it to reduce friction. These bearings are less expensive than ball bearings but tend to wear out faster and are noisier over time.

- High-Quality Ball Bearings (Deep Groove Bearings): High-end or industrial ceiling fans often use deep groove ball bearings, which are designed for high-speed and high-load conditions.These bearings are more durable and can handle higher operating speeds while generating less noise.

- Angular Contact Ball Bearings: Some premium ceiling fans may use angular contact ball bearings, which are designed to handle both radial and axial loads. These types of bearings provide better performance in high-load applications but are more expensive.

- Hydrodynamic Bearings (Less Common): Very high-end or industrial fans might use hydrodynamic bearings, which rely on a thin film of lubricant to keep the components separated, reducing friction and wear. These are typically found in specialized applications and are not common in residential ceiling fans.Bottom of Form

Q-23: How many size ceiling fan available in the market?

Answer:

- 36 inches

- 48 inches

- 56 inches.

Q-24: How do ceiling fans work?

Answer: Ceiling fans circulate air to create a wind-chill effect that cools the body. The blades spin, pushing air downwards in the summer to help with cooling. In winter, the fan can be reversed to circulate warm air that gathers near the ceiling back down to the floor.

Q-25: What is the difference between a DC motor and an AC motor in ceiling fans?

Answer:

- AC (Alternating Current) motors are more common and less expensive. They tend to consume more electricity and generate more noise.

- DC (Direct Current) motors are more energy-efficient, quieter, and usually have more speed settings but are typically found in higher-end ceiling fans.

Q-26: How do you reverse the direction of a ceiling fan?

Answer: Most ceiling fans have a switch on the motor housing or a remote control button to reverse the direction of the fan. In the summer, the blades should rotate counterclockwise to blow air down, and in the winter, the blades should rotate clockwise to circulate warm air upward.

Q-27: How long should a ceiling fan last?

Answer: With proper maintenance, a ceiling fan can last 10-15 years. Regularly cleaning the blades and lubricating the motor can extend the life of the fan.

Q-28: Why is my ceiling fan making a noise?

- Answer: Noises can come from several sources:

- Wobbling blades: Check if the blades are balanced.

- Loose parts: Tighten screws or other components.

- Bearing issues: The motor bearings may need lubrication or replacement.

- Dirt buildup: Dust on the blades or motor can cause noise.

Q-29: Is it okay to use a ceiling fan in winter?

Answer: Yes, ceiling fans can be used in winter. By reversing the fan’s direction to clockwise, the fan will pull the cooler air upward and push the warm air that accumulates near the ceiling back down, helping to evenly distribute heat.

Q-30: Do ceiling fans use a lot of electricity?

Answer: Ceiling fans are relatively energy-efficient compared to air conditioners. A typical ceiling fan uses about 75 watts of electricity on high speed. DC motor fans are even more energy-efficient than AC motor fans.

Q-31: Why does my ceiling fan turn on by itself?

Answer: A ceiling fan might turn on by itself due to:

- Faulty remote control: Check the remote’s settings or replace the batteries.

- Electrical issues: A wiring issue or a power surge can cause the fan to turn on unexpectedly.

- Interference from other devices: If you have other devices with remote controls, they may interfere with your fan.