Electrical Busbar

A busbar is a metallic strip or bar (usually made of copper or aluminum) used for conducting electricity within a switchboard, distribution board, substation, or other electrical apparatus. It serves as a central point where incoming and outgoing electrical currents are distributed.

✅ Key Points:

- Made from copper or aluminum due to high conductivity.

- Used to reduce energy loss and enhance reliability.

- Can carry large currents.

- Common in substations, power plants, and industrial setups.

- Types: Single busbar, Double busbar, Ring busbar, etc.

Primary materials used for busbars

The primary materials used are copper and aluminum. Copper is favored for its high conductivity and strength, while aluminum is lighter and more economical, although it requires a larger cross-section for the same current carrying capacity and needs special considerations for connections due to its oxide laye

🔁 Bus Coupler

A bus coupler is a switch (often a circuit breaker) used to connect two separate busbars in an electrical system. It allows power to flow from one busbar to another, either during maintenance, load balancing, or fault conditions.

✅ Key Functions:

- Connects or isolates two busbars.

- Provides operational flexibility.

- Helps in transferring load in case of busbar failure.

- Can be manual or automatic.

🧩 Example in a Substation:

- Busbar A feeds a set of loads.

- Busbar B feeds another set.

- A bus coupler connects A and B.

- If Busbar A fails, the coupler allows Busbar B to temporarily take over.

Different operating modes of a bus coupler:

A bus coupler can operate in several modes:

- Normally Closed (NC): The bus coupler is typically closed, keeping both bus sections connected. It opens only during specific events like faults or for maintenance.

- Normally Open (NO): The bus coupler is typically open, keeping the bus sections separate. It closes only when required for load transfer, redundancy, or fault clearance.

- Automatic Transfer Scheme: The bus coupler operates automatically in response to certain conditions, such as a fault on one bus section, to maintain supply.

The typical interlocking requirements for a bus coupler:

Interlocking is crucial for safe and correct operation. Typical interlocks might include:

- Electrical Interlock: Prevents parallel operation of transformers/sources unless specific conditions are met (e.g., phase angle synchronization).

- Mechanical Interlock: Prevents simultaneous closing of certain breakers to avoid hazardous conditions (e.g., short-circuiting two different feeders directly).

- Load Shedding Interlock: May open or prevent closing if the connected load exceeds the capacity of the remaining power source.

- Protective Relaying Interlock: Prevents closing if a fault condition persists.

What considerations are important when selecting a bus coupler?

Key considerations include:

- Voltage and Current Ratings: Must match the system requirements.

- Short-Circuit Breaking Capacity: Must be able to safely interrupt the maximum fault current.

- Operating Mechanism: Manual, motor-operated, or spring-charged for rapid closing.

- Protection Requirements: Integration with protective relays for overcurrent, earth fault, etc.

- Interlocking Needs: To ensure safe operation within the system.

- Space and Environmental Conditions: Physical dimensions and suitability for the operating environment.

What is Bus Coupler And Bus Riser?

- A Bus Coupler connects two horizontal busbar sections on the same level to provide operational flexibility and redundancy.

- A Bus Riser provides vertical power distribution by connecting busbars or electrical panels on different levels or floors.

- A bus coupler is a device that connects two buses together so that they can communicate with each other. A bus riser is a device that allows a bus to be raised up so that it can be connected to another bus or system.

Here are 10 questions and answers about electrical busbars:

- What are the main functions of a busbar in an electrical system?

- Answer: The main functions include:

- Distributing electrical current from a source to multiple loads or circuits.

- Collecting current from multiple sources (e.g., generators) to feed a common load.

- Providing a convenient point for connecting and disconnecting electrical equipment.

- Acting as a rigid conductor to support electrical components.

- Answer: The main functions include:

- What are the different types of busbar arrangements commonly found in substations?

- Answer: Common arrangements include:

- Single Busbar: Simple and economical but lacks redundancy.

- Single Busbar with Sectionalizer: Improves reliability by allowing isolation of faults in one section.

- Double Busbar: Provides high reliability and flexibility, allowing maintenance on one bus while the other remains energized.

- Ring Busbar: Offers high reliability and allows power flow in two directions, minimizing interruption during a fault.

- Breaker-and-a-Half Scheme: Very reliable and flexible, allowing any breaker to be taken out of service without interrupting power.

- Answer: Common arrangements include:

- What factors influence the sizing of a busbar?

- Answer: Key factors include:

- Current Carrying Capacity (Ampacity): The maximum current the busbar needs to carry without overheating.

- Temperature Rise Limits: The allowable temperature increase above ambient.

- Short-Circuit Current Withstand: The ability to withstand high fault currents without damage.

- Voltage Drop: Ensuring acceptable voltage levels along the busbar.

- Mechanical Strength: To withstand electromagnetic forces during short circuits and support connected equipment.

- Space Constraints: Physical limitations within the enclosure.

- Answer: Key factors include:

- Why is proper jointing and termination of busbars important?

- Answer: Improper jointing can lead to:

- Increased Resistance: Resulting in excessive heat generation and power loss.

- Hot Spots: Which can damage insulation, deform the busbar, and lead to premature failure.

- Voltage Drop: Affecting equipment performance.

- Arcing and Fires: Due to poor contact. Proper termination ensures a low-resistance, reliable connection.

- Answer: Improper jointing can lead to:

- What is the significance of busbar insulation?

- Answer: Insulation (e.g., heat-shrinkable sleeves, epoxy coating, air gaps) is important for:

- Preventing short circuits between busbars or between busbars and ground.

- Ensuring personnel safety by providing electrical isolation.

- Protecting the busbar from environmental factors like dust, moisture, and chemical contamination.

- Reducing the physical clearances required between conductors.

- Answer: Insulation (e.g., heat-shrinkable sleeves, epoxy coating, air gaps) is important for:

- How do electromagnetic forces affect busbars during a short circuit?

Answer: During a short circuit, extremely high currents flow through the busbars. These currents create strong magnetic fields, which exert significant electromagnetic forces (Lorentz forces) on the busbars. These forces can cause the busbars to bend, twist, or even rupture if they are not adequately supported and designed to withstand such stresses.

- What are some common busbar accessories?

Answer: Common accessories include:

- Busbar supports/insulators: To hold and insulate the busbars.

- Connectors/clamps: For making connections to other busbars or equipment.

- Flexible connectors: To accommodate thermal expansion or vibration.

- Protective covers/shrouds: For safety and environmental protection.

- Expansion joints: To allow for thermal expansion and contraction.

- What are the advantages of using a segregated or isolated phase busbar system?

Answer: Segregated or isolated phase busbar systems enclose each phase conductor in its own metallic casing, providing:

- Higher Short-Circuit Withstand: Prevents phase-to-phase faults.

- Enhanced Safety: Reduces the risk of personnel contact with live conductors.

- Improved Reliability: Faults are typically confined to a single phase, making them easier to locate and clear.

- Reduced Electromagnetic Interference: Due to the shielding effect of the enclosures. They are often used in high-voltage and high-current applications, such as power plants and large industrial facilities.

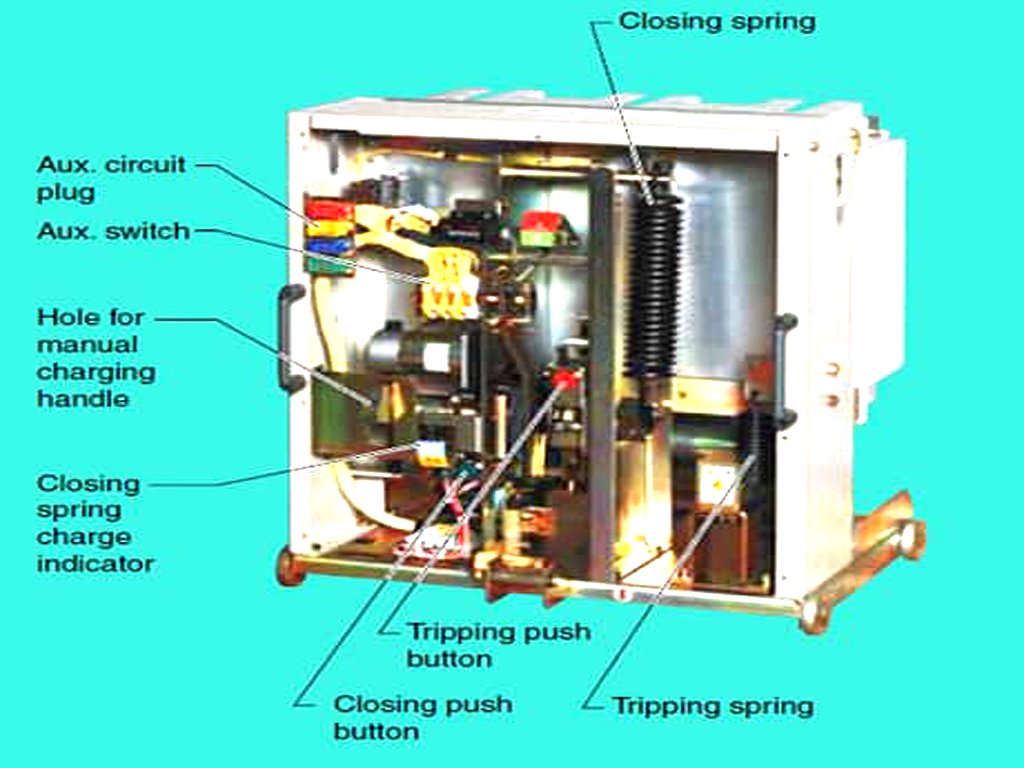

- What type of protective device is commonly used as a bus coupler?

Answer: A circuit breaker is most commonly used as a bus coupler. This is because circuit breakers can interrupt fault currents, be operated remotely, and are designed for frequent operation. In some lower-voltage or less critical applications, a heavy-duty switch-disconnector might be used, but a circuit breaker offers superior protection and control

- Explain the role of a bus coupler in a double busbar arrangement.

Answer: In a double busbar arrangement, there are two main busbars (Bus 1 and Bus 2). Feeders can be connected to either bus. A bus coupler connects Bus 1 and Bus 2. This arrangement allows:

- Any feeder to be transferred from one bus to the other without interruption.

- Maintenance on one bus while the other remains energized and supplying loads.

- Increased flexibility for system expansion and fault management.